Buehler adds UH4000 Series Universal Hardness Tester for process control

February 12, 2019

By Manufacturing AUTOMATION

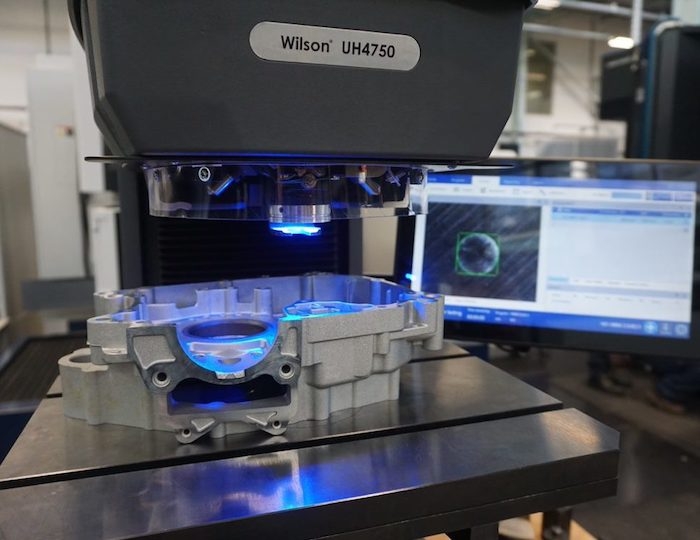

February 12, 2019 – Buehler has added the new UH4000 Series Universal Hardness Tester to its line of measurement tools for process control.

The Wilson UH4000 series tests Rockwell, Vickers, Knoop and Brinell hardness scales within the selected tester load range, and comes in two configurations: UH4250 Hardness Scale 0.5-250 kgf and UH4750 Hardness Scale 3-750 kgf.

The tester has a sturdy steel casting frame, which the company says ensures durability in production and workshop environments. The hardness test process is controlled by DiaMet hardness control software. With this software integration, it is suited for quality control and process control applications, whether it tests large or small manufactured components in the lab or directly on the production floor.

The testers feature a closed-loop loading cycle for best accuracy, faster testing cycles and a new eight-position turret to hold desired combination of indenters and objectives. It has a large 300 mm x 400 mm T-slot stage with high weight capacity, enabling the testing of heavy and large parts nondestructively. An optional clamping tool is available to ensure stability during the test process; both manual and automatic stage movement options are also available.

Other features include an anvil adapter/extension for small parts handling, a ring light for accuracy in Brinell measurements, an automatic/mechanical motorized vertical stage, and a red target laser cross for position testing.

The UH4000 Series is designed for rugged environments and suits testing in the automotive industry, metals production and large components such as castings and forgings, flat or cylindrical work pieces, steels, heat-treated materials, cemented carbides, ceramics and plastics and carbon testing.

Advertisement

- Eaton releases high-density rack power distribution unit

- OCTOPUZ releases new robotic programming software