Five-axis horizontal machining centre

May 9, 2011

By

Mary Del

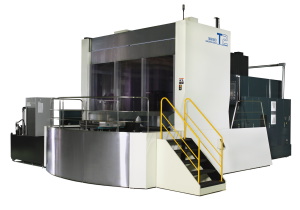

Makino’s new T2 five-axis horizontal machining centre is designed for mid-sized titanium aerospace part production. Its purpose-built design provides the rigidity, dynamic stiffness, vibration damping and agility necessary for more productive titanium machining and longer tool life, the company says. The T2 provides X-, Y- and Z-axis travels of 2,000 mm, 2,000 mm and 1,800 mm, respectively, allowing for part sizes up to 1,900 mm by 2,000 mm and 5,000 kg. The T2’s construction features large way surfaces and table casting for extra rigidity and vibration damping, as well as a 120-position automatic tool changer (up to 190 available) for continuous, uninterrupted machining. The T2’s HSK-A125 spindle is Makino’s most powerful spindle to date, delivering higher torque, horsepower and clamping force than all predecessors. The T2 includes an automatic pallet changer system that features continuous operation and eliminates costly downtime for part changeovers with pallet change times of only 60 seconds, according to the company.

Makino’s new T2 five-axis horizontal machining centre is designed for mid-sized titanium aerospace part production. Its purpose-built design provides the rigidity, dynamic stiffness, vibration damping and agility necessary for more productive titanium machining and longer tool life, the company says. The T2 provides X-, Y- and Z-axis travels of 2,000 mm, 2,000 mm and 1,800 mm, respectively, allowing for part sizes up to 1,900 mm by 2,000 mm and 5,000 kg. The T2’s construction features large way surfaces and table casting for extra rigidity and vibration damping, as well as a 120-position automatic tool changer (up to 190 available) for continuous, uninterrupted machining. The T2’s HSK-A125 spindle is Makino’s most powerful spindle to date, delivering higher torque, horsepower and clamping force than all predecessors. The T2 includes an automatic pallet changer system that features continuous operation and eliminates costly downtime for part changeovers with pallet change times of only 60 seconds, according to the company.

www.makino.com

Advertisement

- Five-axis machining and machine support

- Inspections announced for summer jobs, labour group says it’s not enough