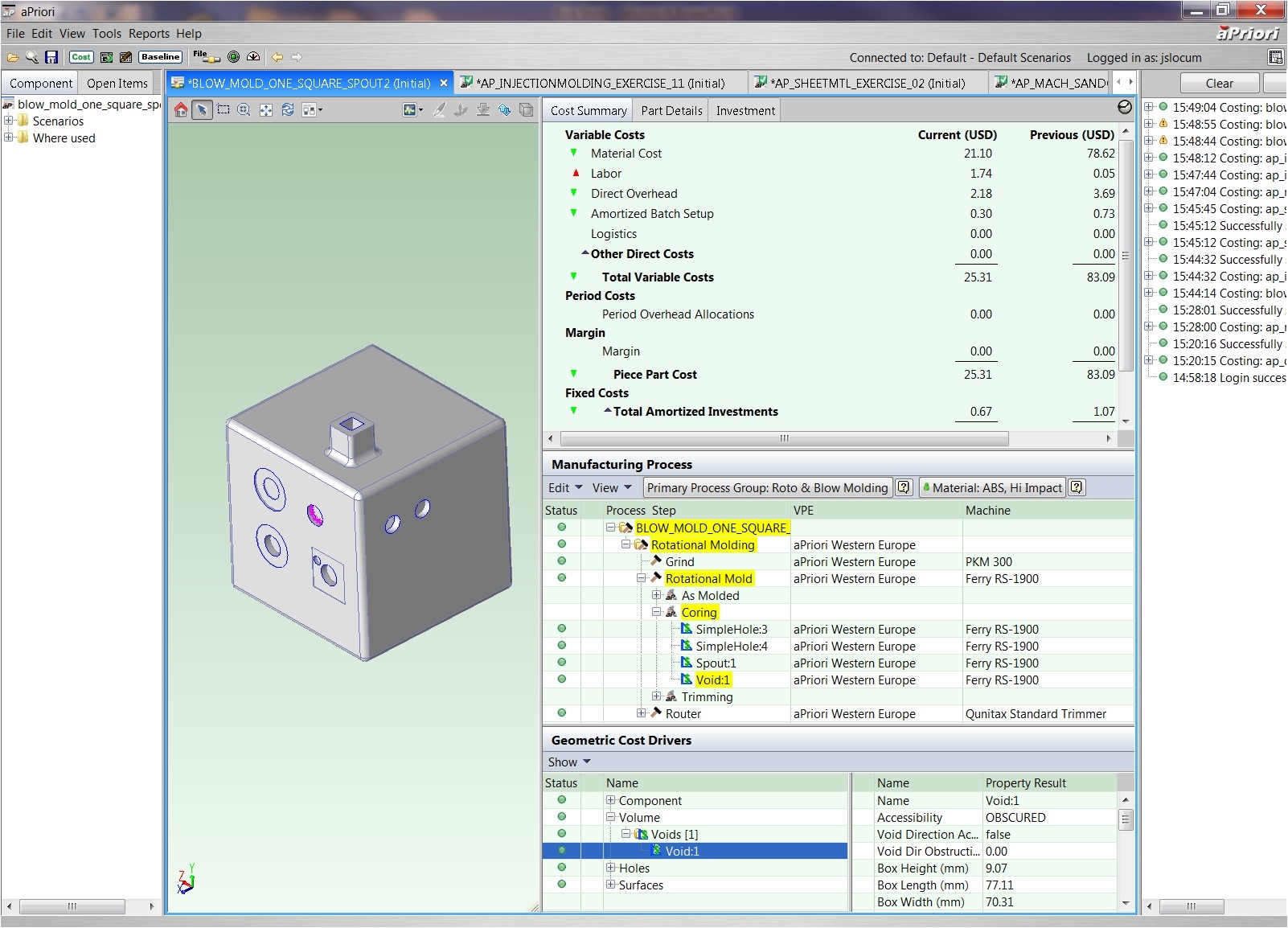

aPriori’s 2011r2 offers new functionality and enhancements that expand the platform’s cost optimization capabilities for companies with high tolerance machining requirements in the automotive, oil and gas, semi-conductor equipment manufacturing and aerospace/defence segments. Also, in response to the growing market need for better methods to estimate the cost of hard tooling that can be used by tooling experts, as well as non-experts, aPriori has significantly upgraded its capabilities to generate highly detailed tooling cost estimates for components. The Product Cost Management software platform is able to instantly and precisely determine the cost of a part or product from a CAD model, based on the manufacturing process, materials to be used and the factory or region where it will be produced. As design changes are made, or new product specs are introduced, the software automatically re-assesses and provides an updated product cost quickly and easily, the company says. Using this new level of cost knowledge, companies can make more informed design and production decisions and significantly reduce product costs throughout the entire product life cycle. Upgraded features include new and expanded baseline costing processes, detailed tooling estimates for plastic and stamped parts, tools to more efficiently cost components and leverage cost data, and expanded platform support.