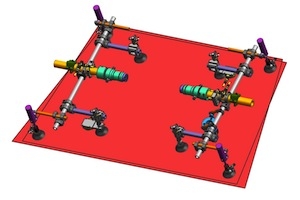

Bilsing Automation recently developed a flexible destacking solution that can successfully separate and feed both steel and aluminum blanks in various sizes and configurations. The solution was designed and engineered by Bilsing for flexibility where the end effector can handle multiple parts. It is comprised of the company’s 2.5” diameter aluminum round-body tooling and other Bilsing components. Where traditional steel blank destacking systems rely on magnetic holders for separating the blanks before lifting and transfer, aluminum has no magnetic qualities. Typical aluminum destacker systems employ peel cylinders to lift the corners of the blank with air knives that shoot air in that space to break the vacuum. Another issue is that lubrication on the blanks acts like a glue-agent, causing the blanks to stick together. To overcome these issues, Bilsing compiled field data for strategic placement of the peel cylinders in its design. During a cycle, the automation lowers so that the peeler suction cups are all level, with the front cups being spring-loaded and programmed to fire just slightly prior to the other cups. The air knives then fire to help peel back the top sheet, breaking the vacuum, which assists in separating the blanks.

www.bilsing-automation.com