Robot tool changer control

November 10, 2010

By

Mary Del

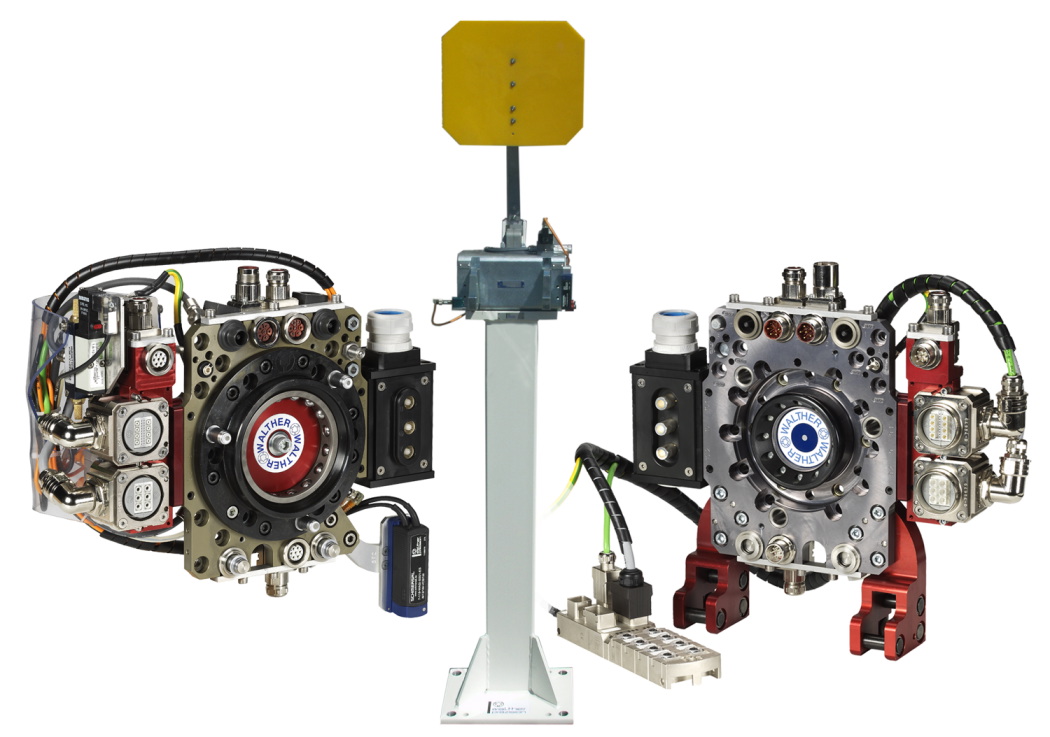

WALTHER-PRÄZISION has focused the development of its latest tool changer control, WASI 2, towards the highest possible safety level. The WASI 2 system is well suited for use in automated systems, the company says. This is how it works: During tool changing outside the protected tool parking station (robot cell), an emergency stop function, integrated into WASI 2, prevents the locking mechanism from releasing. If an error message occurs, it is only possible to restart the system after it has been enabled. Consequently, an uncontrolled disconnection is safely ruled out. An enable signal, however, will only be given in the safe area. The connection cycle and thus the safe operation can then be resumed via the robot control.

WALTHER-PRÄZISION has focused the development of its latest tool changer control, WASI 2, towards the highest possible safety level. The WASI 2 system is well suited for use in automated systems, the company says. This is how it works: During tool changing outside the protected tool parking station (robot cell), an emergency stop function, integrated into WASI 2, prevents the locking mechanism from releasing. If an error message occurs, it is only possible to restart the system after it has been enabled. Consequently, an uncontrolled disconnection is safely ruled out. An enable signal, however, will only be given in the safe area. The connection cycle and thus the safe operation can then be resumed via the robot control.

These safety properties complement the Robot Tool Master line, tool changers developed by WALTHER-PRÄZISION. The compact and modular designed tool changing systems may be equipped with various connector elements for a wide range of fluid and gaseous media. Also, a large number of signal plugs, measuring lines, power and welding connectors as well as connectors for Profibus and Profinet, which are also available in fibre optic versions, can be integrated.