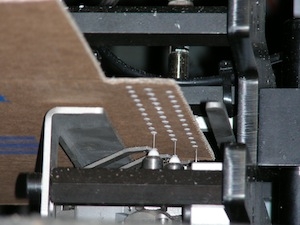

The new ERO-OE high-pressure gluing system from Haeco brings extra high-speed production, low maintenance and up to 40 per cent lower glue usage to casemaker/flexo-folder machines. The ERO-OE glue system has a maximum production speed of more than 2,000 fpm, and uses ceramic nozzles to prevent the formation of dried glue, eliminating daily washing. Unique in the industry, the system can apply glue in a dot pattern, as well as stripes, reducing glue consumption up to 40 percent. The ERO glue detection system uses a 640X480-pixel resolution black-and-white camera capable of capturing 60 frames per second. It mounts on the gluing station and is monitored via the control’s 12-inch touchscreen. A data analyzer, encoder frequency divisor and LED stroboscopic illuminator are all housed in a compact electrical cabinet. The glue detection system is “mastered” by running a well-glued box through. An auto-learning system then records the image and compares all other boxes with the good sample. Boxes with glue volume or position outside the tolerance threshold are marked with ink or UV liquid. The maximum error is ±0.0625″ at 1600+ fpm, and the smallest readable dot is 0.06″ diameter at 650 fpm.

www.haeco.us