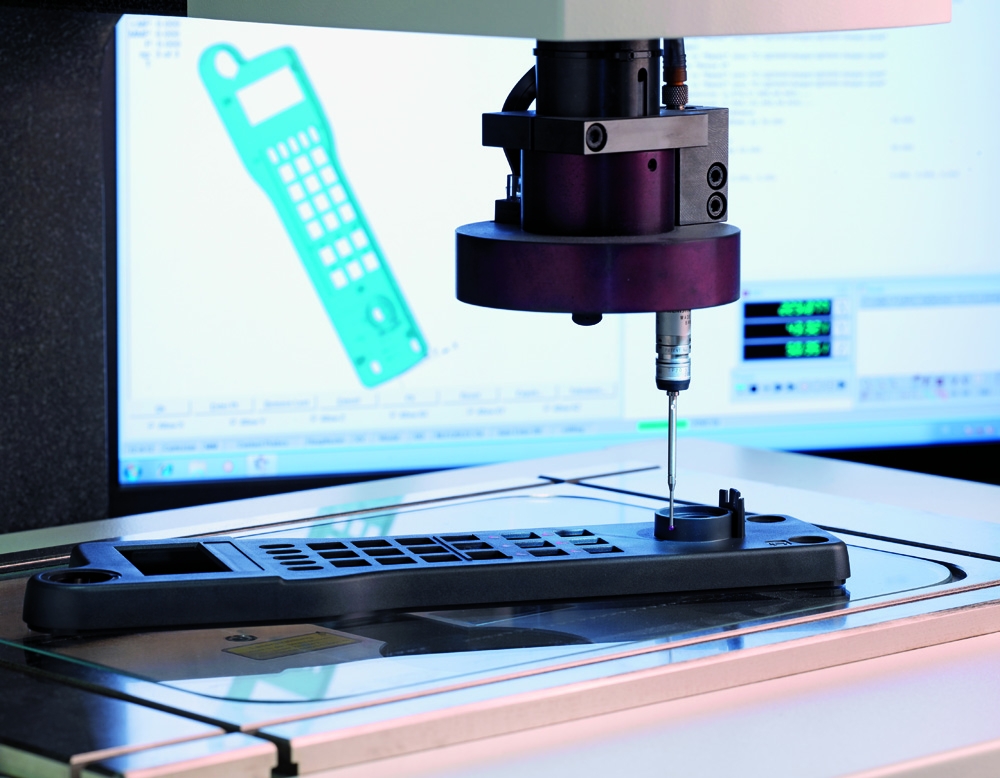

Offering a new 3-D profiling capability to inspection measurement, Heidenhain’s IK 5000 QUADRA-CHEK PC software system is designed to give operators the ability to quickly measure and determine parts profiles within desired tolerance zones. This optional 3-D feature compares the actual measured part to a three-dimensional model within the PC software. To use the 3-D Profiling, the operator first imports a computer-generated 3-D model using IGES or STEP formats and then takes measurement points on the desired part. This new function fits and compares the two within the IK5000, and then both the overall profile and the individual point results can be toleranced, printed and/or exported for evaluation. The measurement and evaluation routines of 3-D contours using the IK 5000 makes inspection on CMMs and multisensory measurement inspection machines an easy process. These part programs can then be used to take measurements of subsequent parts either manually or in an automated measuring process depending on the machine design.

www.heidenhain.us