Manufacturer significantly cuts development time with HMI software

February 28, 2014

By Blake DeBiasio

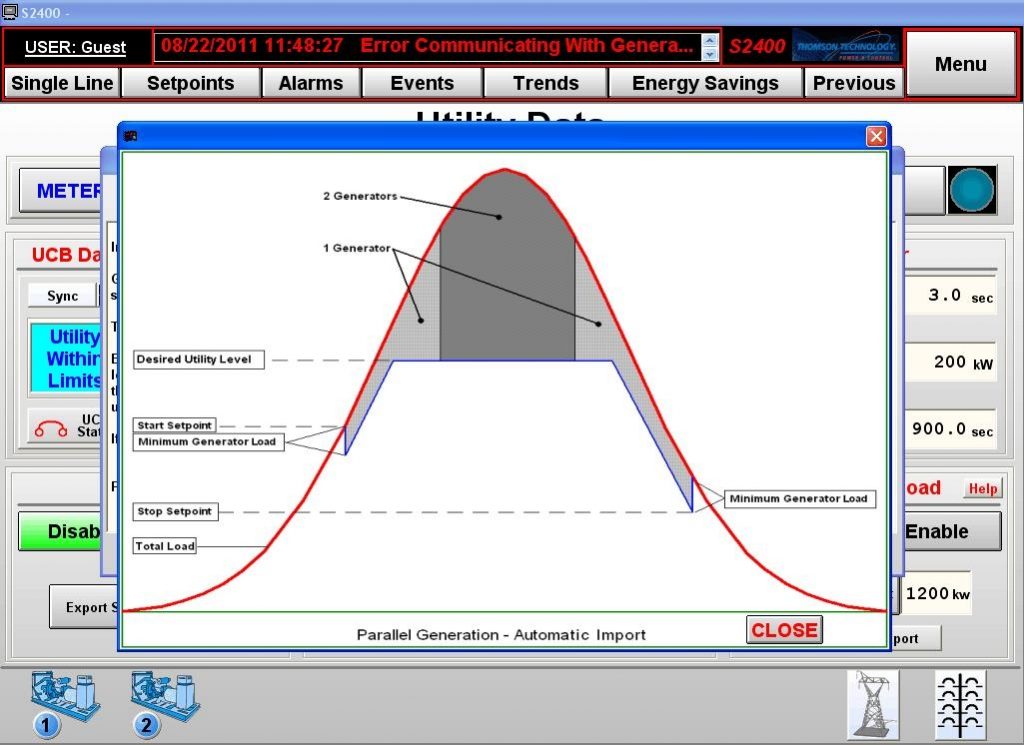

The SCADA/HMI Scheduler is capable of reading hundreds of setpoints and displaying them all in a visually intuitive manner.

The SCADA/HMI Scheduler is capable of reading hundreds of setpoints and displaying them all in a visually intuitive manner.

A manufacturing facility is only as reliable as its power source, as much of the equipment in those facilities must have a robust supply of electrical power. That’s why the low- and medium-voltage switchgear and other power control products produced by Thomson Technology are so critical for facility power generation infrastructure. Such products require an equally reliable SCADA and HMI solution.

Thomson Technology has been developing, designing and manufacturing power generation controls and switchgear since 1973. We provide systems for critical applications such as health care, data centres, water/wastewater treatment plants, and oil and gas exploration. Our wide variety of customers presents challenging and ever-changing demands, and we needed a SCADA/HMI capable of meeting these mandates.

Searching for a solution

No OEM likes to switch critical components, but we realized the time spent in development of SCADA/HMI screens and related functionality for our switchgear systems was preventing us from meeting our crucial objective of providing our customers with the shortest possible lead times.

For several years, we custom programmed our SCADA/HMIs using many well-known software products and related development platforms. While these products allowed us to create acceptable SCADA/HMI solutions, we couldn’t find what we really wanted — a software product that offered both the reliability of a hardware-based platform and the flexibility of a hardware-independent solution. In addition, we spent too much time and effort in application development because the software products, particularly the development platforms, we were using were cumbersome and hard to program.

Once Thomson Technology made the decision to find a solution to our SCADA/HMI problem, we started with a list of requirements that had to be met, including flexibility, easy customization, seamless scheduling and extensive communication capabilities.

We needed to create new projects based on a basic template that would let us quickly customize the SCADA/HMI for each switchgear product based on the intended application. The new SCADA/HMI development platform had to let us customize a new project by simply selecting options during the configuration process, as opposed to performing custom programming.

The same standard SCADA/HMI program also had to be able to perform different tasks based on the features selected. The SCADA/HMI configuration process had to include automatic screen layout changes based on information entered. It also needed to include a built-in simulator that would allow us to test new features or troubleshoot existing projects.

The ability to save and load the project configurations in our own file structures was critical. This feature, in combination with the simulator, would enable us to quickly load a site configuration without changing the basic program. We also needed to run tests to offer support to the service department, or to simply develop a new project quickly.

To keep the HMI intuitive, we needed complete control over the design of our interfaces. To include advanced information to operators, we would need the functionality to develop HMI solutions with pop-up help screens, messages and indicator lights that would detail the meaning of each individual set point in the application. Any conflicts or illegal operations, as well as the status of communication with field devices, would also have to be diagnosed and depicted on the screens.

Customers in control

We wanted our customers to have control over their SCADA/HMI, so we looked for a development platform that would enable changes to be made during runtime without stopping program execution. Customers needed the ability to add or remove users, edit communication parameters, configure their own web server for remote monitoring, generate reports from history files, and configure the application to send automatic emails when the system triggered alarms — all without taking the SCADA/HMI offline.

Because the scheduler we implemented can use hundreds of setpoints, a good display that enabled the user to edit in a visually intuitive way was important. Just as significant was the ability to save and load all the scheduler setpoints to a file to save time when entering hundreds of setpoints. Furthermore, it had to be easy to deploy these setpoints at multiple sites.

Finally, it was imperative that our new SCADA/HMI software serve as a communication gateway between devices. It should be able to acquire data from engine controllers, meters, protection relays and other devices. It also had to provide a central monitoring and logging platform to send the information further up the chain to integrate with other SCADA systems.

The right fit

The solution that we found to this challenging set of requirements was the InduSoft Web Studio SCADA/HMI software and development platform. The software’s Rapid Application Configuration Environment development platform, displayed as a ribbon interface, helped us cut development time by 60 per cent. This in turn cut our costs, and reduced lead times for delivery of switchgear systems to our customers.

Using InduSoft, Thomson Technology designed a custom application template for use in our Series 2400 switchgear. Each system in this series is delivered with an integrated SCADA/HMI that offers options for communication with the Building Automation System, the Building Management System, the plant monitoring system and other customer systems.

Our application offers standard communications through Modbus Serial, Modbus TCP and OPC. Virtually any protocol is available through InduSoft’s native drivers, from DNP 3.0 to BACnet.

By finding a better SCADA/HMI solution, we were soon able to incorporate other features as well. We could now make minor changes on-site with only the runtime license installed. This saved us the time, trouble and expenses of taking a PC with the InduSoft development system software installed to the site.

We can now also provide our customers with the option of multiple remote stations delivered using the InduSoft Web Thin Client, which is important for our oil and gas as well as water/wastewater customers.

In addition, we now offer a “Virtual Technician” that enables us to remotely connect to the local switchgear SCADA/HMI over the Internet, allowing us to diagnose problems and make adjustments without travelling to the site. This saves us time and, more importantly, lets us help customers faster and more economically since we no longer need to send a technician to the site.

By switching to InduSoft Web Studio, we’ve cut down on SCADA/HMI programming time by 60 per cent per project. We’re also able to offer a much more feature-rich application with many more communication options, along with a standardized and easily serviceable installation. Data logging and remote maintenance features are now also offered, both of which didn’t exist in previous applications.

By taking the time to find the right SCADA/HMI platform, we reduced our costs while providing a better product and improved customer satisfaction.

Blake DeBiasio is an engineering manager with Thomson Technology. DeBiasio graduated from the British Columbia Institute of Technology in 1986 with a Diploma of Technology in Control Electronics. He began his career with Thomson Technology in June 1986 as the junior electrical designer for power generation system, and currently manages the team dedicated to designing power generation switchgear systems.

Advertisement

- Standalone safety controller

- Ontario investment in automotive door and seat manufacturer to create and retain hundreds of jobs in the province