Safe full-stop detection

August 19, 2009

By Manufacturing AUTOMATION

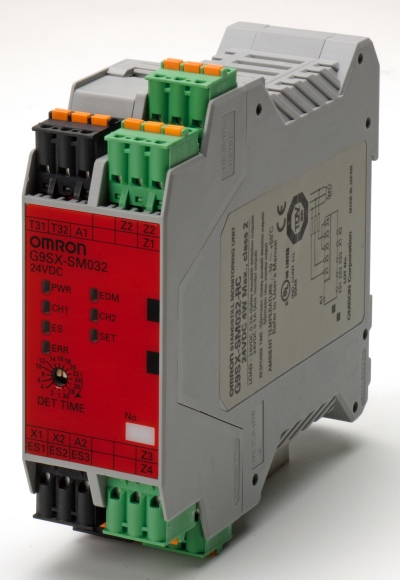

Machine operators can now reduce their downtime by implementing the new G9SX-SM Standstill Monitoring Unit from Omron into their machines.

Machine operators can now reduce their downtime by implementing the new G9SX-SM Standstill Monitoring Unit from Omron into their machines.

Typically, when access to a hazardous area is required when there are moving parts within that area, either timers or sensors are used to grant access. Sensors can be tricky to implement safely in situations where the motion can stop at any position, or if space is limited. Timers are more commonly used, however the problem with this technique is that the timers need to be set based on a worst case scenario, which can prevent access to the machine longer than is necessary. Machines also have a tendency to mechanically deteriorate over time and with fixed timers, this cannot easily be accounted for.

What the G9SX-SM does differently is to monitor the back-EMF from the motors directly producing the motion in the hazardous area. By doing this, the G9SX-SM knows exactly when the movement has stopped, and will grant access immediately, regardless of how long it may take. The G9SX-SM is currently the only device on the market that can do this and maintain a Category 4 (EN954-1), SIL 3 (IEC/EN 62061), and PLe (ISO13849-1) rating.

The solid state design of the G9SX-SM is also safe to use with inverters and is particularly well suited for use on machines with high or variable inertial loads when the stopping time can vary significantly.” Examples of this are CNC machines, flywheels on power presses, centrifuges, and saws or grinders.

Additional information can be found at www.ia.omron.com under Safety Components / Safety Application Controllers, or by simply contacting your local Omron representative.