Kuka Systems debuts Pulse line technology

September 22, 2015

By Manufacturing AUTOMATION

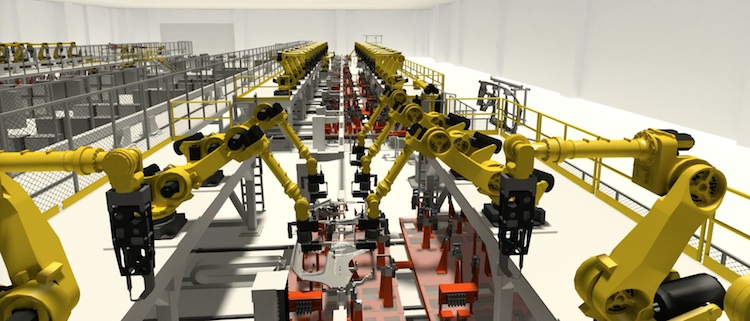

Sept. 22, 2015 – Kuka Systems North America has launched the Pulse carrier conveyance system for automotive car body assembly lines.

The concept utilizes linear synchronous motor technology provided by MagneMotion to move body sections through robotic work stations along assembly lines as joining and other functions are performed. According to the company, Pulse technology is “extremely fast and flexible” and 30 per cent faster than conventional friction-based transfer systems. The line uses solid state linear motors, giving the Pulse system fewer wear components that require maintenance causing unscheduled downtime, says the company. A Pulse line can be configured to handle up to four models, notes Kuka Systems, and boasts a flexible design that allows it to be adapted to the physical conditions at each assembly plant.