Five-axis machining and machine support

May 9, 2011

By

Mary Del

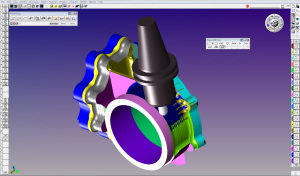

Gibbs and Associates, developer of GibbsCAM software for programming CNC machine tools, recently unveiled improvements within GibbsCAM 2011, including additions and enhancements to five-axis machining and multi-task machining (MTM). New features include:

Gibbs and Associates, developer of GibbsCAM software for programming CNC machine tools, recently unveiled improvements within GibbsCAM 2011, including additions and enhancements to five-axis machining and multi-task machining (MTM). New features include:

• Five-axis hole-making – A new routine for five-axis hole-making operations, aided by enhancements to GibbsCAM’s automatic feature recognition, makes programming five-axis drill cycles much easier and much more efficient, the company explains.

• Five-axis toolpath conversion – A new Operation Modifier allows converting 2.5- and three-axis toolpaths for machining in five-axis, which enables use of shorter tools to achieve smoother toolpaths at certain surface intersections and other geometric conditions.

• Five-axis machining styles – Additional swarf cutting capabilities have been added, as well as a new five-axis trimming (wireframe) strategy.

• Five-axis milling on turning machines – Support for B-axis (tilting live tooling) enables programming of five-axis milling with Y-axis offsets on lathes and multi-task machines equipped with a live-tooling B-axis.

• MTM thread whirling – GibbsCAM support of thread whirling attachments is a key addition for multi-task machines with multiple axes (typically running with five-axis simultaneous motion). Thread whirling attachments provide the rigidity and rotary tools to make screws of high length-to-diameter ratio, such as ball screws, worm shafts, feedscrews and acme screws.

www.GibbsCAM.com