New U of Waterloo lab to help companies adopt additive manufacturing

May 25, 2017

By Manufacturing AUTOMATION

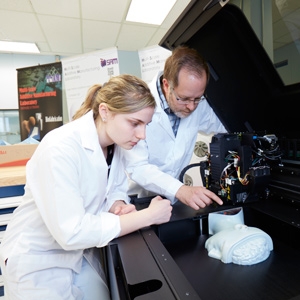

Engineering co-op student Agata Jarkiewicz (left) and managing director Mark Barfoot work together in the Multi-Scale Additive Manufacturing Lab at the University of Waterloo.

Engineering co-op student Agata Jarkiewicz (left) and managing director Mark Barfoot work together in the Multi-Scale Additive Manufacturing Lab at the University of Waterloo. May 25, 2017 – The University of Waterloo says it is building one of the world’s largest university-based facilities to advance additive manufacturing (AM) and help companies adopt these processes.

The project got a major boost this week with the announcement of $8.9 million in funding through the Federal Economic Development Agency for Southern Ontario. Combined with $6.2 million from the province, that makes it the largest-ever government investment in AM at a Canadian university.

In addition to the governments of Canada and Ontario, numerous industry partners and the University of Waterloo itself also contributed cash and in-kind support to the lab.

Backed by nearly $27 million in funding and in-kind support, the lab aims to help Canadian companies tap in the “enormous potential of AM,” explains the institution, while also further developing the technology through research that will involve at least 14 professors and dozens of engineers, post-doctoral fellows, graduate students and co-op students. When fully equipped, the Waterloo lab will be one of the 10 largest university-based AM facilities in the world, it says. Researchers will also collaborate with peer institutions with top AM labs, including those in Germany, the United States, and Singapore.

“Right now, we get a lot of calls from industry about how best to move in this direction,” said Mark Barfoot, managing director of the Multi-Scale Additive Manufacturing Lab at Waterloo. “With this lab, we can leverage our expertise to help companies adopt AM to be globally competitive in the new advanced manufacturing economy.”

Experts at the lab will work directly with companies to develop high-value products using AM processes, equipping them to either do their own production or outsource it.

In the place of traditional manufacturing processes that cut and shape individual parts out of blocks of material, AM devices gradually build up by adding layers of material in a process based on three-dimensional computer designs, says the university. As well, AM will give manufacturers much greater design flexibility while also reducing waste and saving energy, it says, adding that AM will help users rapidly prototype and repair, instead of replace, worn or broken parts.

“This will change the entire manufacturing enterprise,” said Ehsan Toyserkani, a professor of Mechanical and Mechatronics Engineering, who leads the Waterloo research team.

AM is still relatively expensive and slow compared to current manufacturing methods, particularly for mass production, but its use is expected to increase dramatically as advancements are made. The Waterloo lab aims to achieve this through end-to-end innovation.

Advertisement

- New ABB Canada HQ opens in Montreal

- Contest opens for $950M “supercluster” plan aimed at creating jobs