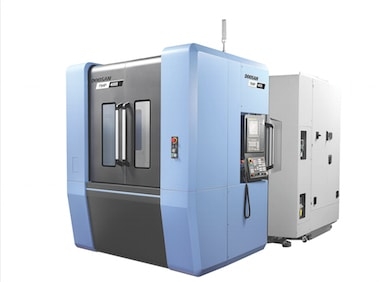

Doosan unveils NHP horizontal machining centres

August 8, 2017

By Manufacturing AUTOMATION

Aug. 8, 2017 – Doosan Machine Tools has introduced the NHP horizontal machining centres series, which it says was built from the ground up for rapid metal removal rates.

Designed to meet the manufacturing demands of industries including automotive and aerospace, the 400-mm pallet NHP 4000 and 500-mm pallet NHP 5000 promise to be “feature-rich yet configurable for a range of applications,” according to the company. The NHP machines come standard with a 15,000rpm spindle with 40 horsepower and 169 ft-lbs of torque. For heavy cutting, a high-torque 15,000rpm spindle with 223 ft-lbs is available, and a 20,000rpm spindle is in development for customers with higher speed precision applications. Up to 1G acceleration/deceleration on X, Y and Z-axes promise to “significantly” enhance productivity, delivering productivity increases of up to 25 per cent over the previous model. Ball screw shaft and bearing cooling systems claim to keep the temperature of fast moving axes stable, ensuring precision machining. The three point levelling design makes machine installation and maintenance much more convenient, notes Doosan, adding that centre-through bed chip management evacuates large volumes of chips quickly for enhanced efficiency.

Advertisement

- New Honeywell ControlEdge PLC promises to “dramatically reduces” integration costs

- Kwik Mark debuts X series dot peen marker