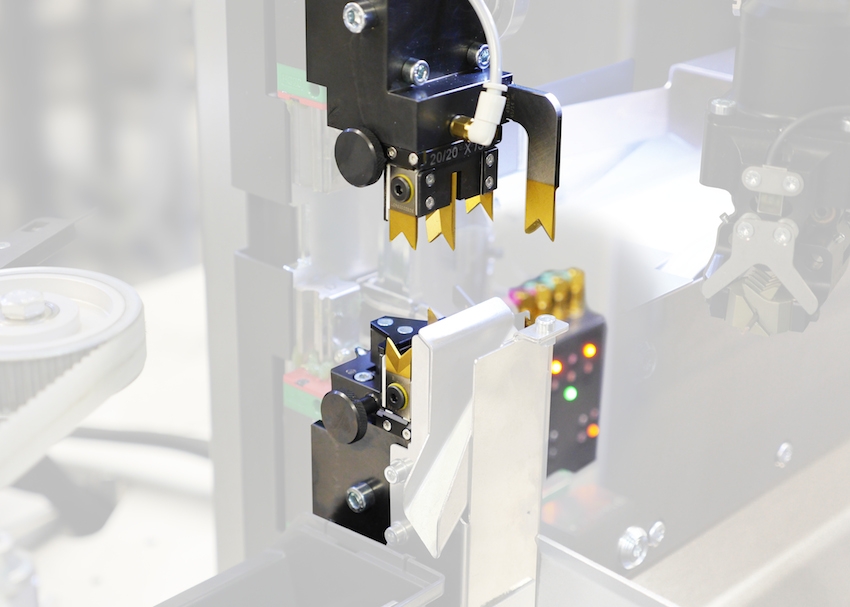

Schleuniger unveils SmartDetect quality monitoring option for CrimpCenters

August 15, 2017

By Manufacturing AUTOMATION

Aug. 14, 2017 – Schleuniger has debuted SmartDetect, a quality monitoring option for Schleuniger CrimpCenters.

The sensor-controlled system monitors the complete stripping process in real time and detects any contact of the stripping blade with the conductor. This allows for improved production quality without sacrificing performance, says the company, adding that individually adjustable system parameters allow the user to set the “perfect combination for optimal detection and minimal scrap.” Tolerance settings refer to percentages and physical units, such as millimeters or inches. During production, SmartDetect improves the quality of the machine’s output while maintaining optimal production rates, says the company. During setup, it gives the operator direct feedback that the stripping parameters are properly set. Handling of the blades and blocks are the same as the standard machine so standard blades and procedures can be used. All connection cables are hidden and fully protected eliminating the chance of damage during normal operation, adds the company.

Advertisement

- EMC names Tonya Starr field service advisor

- Wieland Electric RST16 outdoor connector with type 4X and 6P ratings