MLX300 software option for Yaskawa robots and PLCs

November 15, 2017

By Manufacturing AUTOMATION

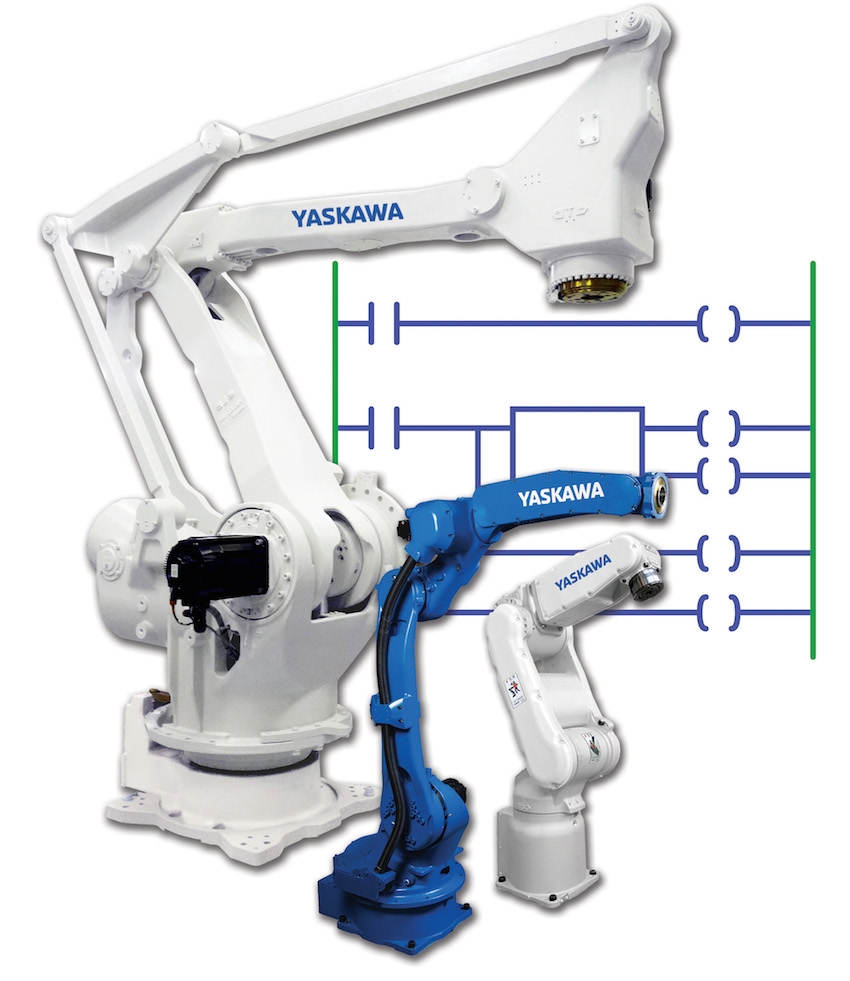

Nov. 15, 2017 – The MLX300 software option is the newest generation of integration for Yaskawa robots and programmable logic controllers (PLCs).

The MLX300 enables operators to control and program Yaskawa robots in a standard PLC programming environment, eliminating the need to learn a specific robot programming language, says the company. All program execution is performed by the PLC; the motion control is handled by the kinematic algorithms of the Yaskawa robot controller. Supported PLCs include CompactLogix, ControlLogix and GuardLogix. Yaskawa says this “unified controls” approach helps to simplify safety design by eliminating redundant electrical interfaces and consolidating hardware to optimize floorspace. Its single controller, single programming environment typically requires a single programmer to implement an application. In addition, familiarity of the controls among maintenance technicians promotes faster troubleshooting and quicker plant acceptance. A set of Add-On-Instructions (AOIs) and HMI screens that are specific to robot configuration and motion control is included. The MLX300 software option is compatible with any Yaskawa DX200 material handling robot or YRC1000 GP-series robot. A combination of up to four robots and positioners can be connected to a single MLX300 system.

Advertisement

- New Denso product catalogue features HSR high-speed SCARA

- N.Y. factories grow at slower pace in November