Advancing manufacturing: Humber College’s Barrett CTI gets support from automation leaders

January 14, 2019

By Kristina Urquhart

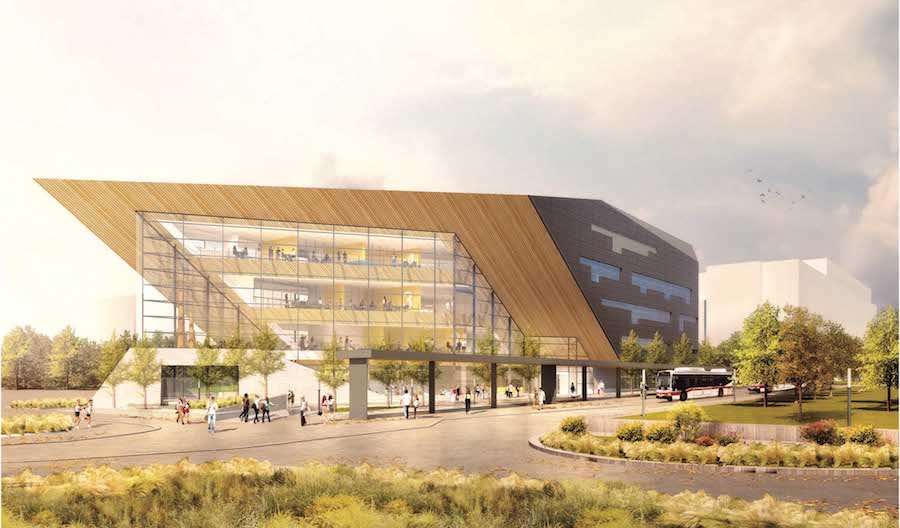

January 14, 2019 – Toronto’s Humber College is set to open the new Barrett Centre for Technology Innovation (Barrett CTI) early this year, backed by a number of major partnerships that will see advanced manufacturing companies working with students and faculty to further knowledge of Industry 4.0–enabled equipment and develop solutions for real-world problems.

“We wanted to work a lot more closely with industry,” says Dr. Darren Lawless, dean of applied research and innovation at Humber College. “One of our passions at Humber is to help our partner companies, especially in the advanced manufacturing sector, grow. These companies then become a pathway for our students to get jobs.”

The school received a $5 million donation from the Barrett Family Foundation in 2016 to fund the 93,000-square-foot centre, which is also allowing Humber to expand its applied research space. “We’d realized that space was a constraint to flexibility,” says Lawless. “[Historically] once a lab is set up, it’s very difficult to change how that lab is configured in a semester or even in a year.”

The solution was to make Barrett CTI a state-of-the-art, modular environment comprised of a series of studios and flexible lab spaces measuring nine by 12 metres. Companies will be able to use a lab for a month or longer to work on business or technical problems with students and faculty, or to demonstrate equipment. Once a project is finished, it can be disassembled and transferred to the building’s fifth-floor storage space for later or modified use.

“Barrett CTI is trying to create the conditions where industry, faculty and students can all collide and where ideas can flow,” says Lawless. “Maybe one of our partners can say, ‘How might we do this?’ And all of a sudden you have a challenge that students and faculty can embrace across multiple disciplines.”

So far, Barrett CTI has signed three- to five-year partnerships with eight major companies; all have also agreed to assist the school with STEM outreach to high school and elementary school students. “We were interested in looking at the leaders in their field,” says Lawless of the selection criteria. “And who had the same vision that we had. In other words, it’s not just about selling equipment.”

Related news

SICK partners with Humber College’s Barrett CTI on sensor education

Humber College adds robotics partnership with KUKA Canada to CTI offering

Humber College and DMG Mori partner on CNC tech and education

For example, Barrett CTI will receive two collaborative robots as part of its agreement with KUKA Canada, which also includes robotics systems integration demonstrations, and virtual reality and simulation technology to assist small and medium enterprises in using vision and conveyor tracking.

Cisco Canada will provide more than $4 million in equipment, including network infrastructure for a Digital Transformation Zone, which not only will assist small businesses in understanding how they can integrate data analysis and automation, but also will expand applied research into how networks communicate with Industry 4.0–enabled technologies.

As the exclusive post-secondary provider for Festo Didactic’s training courses in the Greater Toronto Area, Barrett CTI will offer skills development modules on topics such as hydraulics, pneumatics and industrial wiring. Festo is also establishing a Cyber Physical Factory at the school, which will act as an expandable simulation model to show how automation works across production, logistics and quality assurance channels.

SEW-EURODRIVE will install an Industry 4.0 “living laboratory” focused on automated guided vehicles (AGVs), to demonstrate how mobile technology interacts with people and with automated equipment. DMG MORI Canada will lend machine tooling equipment highlighting the five-axis CNC technology that’s crucial to automotive and aerospace manufacturing; SICK will provide sensor education and an awards program; Cimetrix Solutions will deliver additive manufacturing equipment and scholarship support; and Rockwell Automation will create living labs in mechatronics and connectivity.

“We will have a fully functional lab that will demonstrate to students, employers and faculty that automation does not equal job loss. It just means job refocusing,” says Lawless. “We can train people to do higher-end tasks and let automation do the less high-creativity tasks.”

Barrett CTI will also include a product innovation area for researchers to create prototypes for partner companies, and a skills training hub will allow the school’s multidisciplinary skills teams to practice before international competitions. Manufacturers will be able to use Barrett CTI for corporate training. “We know there are a lot of great companies who have employees who need to be reskilled to take advantage of advanced automation,” says Lawless.

He notes that beyond training current and future workers, the partnerships will serve another purpose to the manufacturing world at large. Participating companies will inevitably put their heads together to see how their respective solutions can come together to solve a bigger problem.

“We know that one plus one sometimes equals three,” says Lawless. “Often new solutions will emerge, which will help our small- and medium-sized companies to grow and hopefully become large companies as well. We really believe that we can work with our partners to make a difference in the Canadian economy and help support the advanced manufacturing sector.”

This article originally appeared in the Winter 2018-19 edition of Manufacturing AUTOMATION’s quarterly e-book, Robotics Insider.

Advertisement

- Ontario autoworkers vow to keep fighting plant closure as GM profits rise

- Ontario premier to meet with GM and union president