Automation in action: Calstone’s custom capabilities

August 30, 2019

By Kristina Urquhart

Investments in automation and a smart pivot in positioning have helped one Canadian manufacturer grow its workforce more than 30 per cent

Calstone

Calstone August 30, 2019 – Lifers – that’s what Jamie Ecclestone, vice-president of marketing at Calstone, calls the staff at her family’s production facility and distribution centre in Scarborough, Ontario.

It’s with good reason: job turnover for the industrial furniture manufacturer is very low, with employees in the machine shop logging anywhere from five to 35 years.

Perhaps it’s Calstone’s ability to innovate that makes workers want to stick around. Or it’s the company’s little-engine-that-could attitude, which took Calstone from 44 staff to 140 in just seven years after landing a contract to supply one of North America’s biggest e-retailers with warehouse workbenches.

Maybe it’s the Ecclestone family’s commitment to achieving net-zero energy output through a comprehensive sustainability program that simultaneously gives back to the environment and the local community.

Or maybe it’s their willingness to invest in people – even after adding new automated machines that have tripled production capacity – by rejigging their org chart to ensure their existing workforce has the chance to retrain and fill new roles.

It was likely a combination of all of these things that led the son of a Calstone employee who’d worked there for 30 years to join his dad on the shop floor. He started off as a programmer before quickly graduating to night production manager. “His dad loved Calstone so much he wanted his son to work here,” shares Jamie Ecclestone. “And because we are adapting and changing the roles so much, [the son] didn’t have to come in as a general labourer. He came in at a higher level. That opportunity is there now – before, it wasn’t.”

The Ecclestone family, from left: Matt, Laura, Jim and Jamie.

Photo: Sandra Strangemore

Advances in automation

Jamie, her brother Matt and her twin sister Laura now run the business alongside their father, Jim Ecclestone, who founded Calstone in 1985 with two business partners before buying them out in 2006.

Calstone got its start with three industrial furniture lines for mailrooms, businesses and warehouses. But since 2012, when Manufacturing AUTOMATION last checked in with Calstone, the needs of the market have changed. Mailrooms are out, and e-commerce is in.

“E-commerce retailers have become the new mailing houses,” says Jamie. “And they need modular pack benches [on which to prepare orders], not little mail slots.” So Calstone has pivoted to focus more on its heavy-duty industrial workbenches for warehouses, with modular designs to fit a variety of picking and packaging scenarios.

Calstone stopped stocking the mailroom product line in January 2019; it is now made to order. They’ve also ceased seeking new clients for their business furniture, though they are still fulfilling their existing contracts. “We have a relationship with these [businesses] and don’t want that to disappear,” says Jamie. “But the impact on the manufacturing side was too much. Our capability of doing long runs of one product is where the cost savings comes in.”

Repositioning was the natural choice after Calstone and its U.S. sales and marketing arm, Dehnco, signed a contract in 2014 to stock the warehouses of a leading e-retailer with thousands of pack benches. That partnership led to more agreements with other retailers – enough of them that Calstone outgrew its 55,000-square-foot facility. Earlier this year, the company opened a second, 80,000-square-foot building just down the road to house all of the offices, assembly and distribution.

Manufacturing remains at the original location, where they’ve upped production to two permanent shifts per day, with a third added as required depending on order volume. New automation equipment has boosted capacity even further.

“We really started to see the increase [after the initial contract], which is why we had to adapt,” says Jamie. “We work with Dehnco on what growth looks like for the year ahead and then figure out how to accommodate that, whether through skilled labour or equipment.”

Calstone’s fibre laser cutting system from Amada Canada. Photo: Sandra Strangemore

They acquired their first fibre laser cutting system from Amada Canada in 2016, which was among the first of its kind installed in Ontario. Volume of production increased substantially, allowing for a decrease in lead times. The results were so impressive that the Ecclestones added a second fibre laser in 2018.

Amada also supplied three hybrid-drive servo-hydraulic press brakes and a turret punch. Matt Ecclestone, Calstone’s vice-president of operations, says they chose Amada as a vendor for its quick turnarounds on equipment orders and the vast inventory of spare parts it stocks in Canada.

“Working with the proper people is important,” notes Jamie, who says the company recently had to spend about $500,000 in upgrades to an automated powder-coating paint line after a botched install from a different vendor less than two years ago. “We’re now on this second round with the proper company, fixing all of the old issues, expanding the line because it wasn’t cooling fast enough,” she says. “The guys couldn’t even take [parts] off the line when it was finished painting because it was so hot.” They’ve since expanded the line to include a longer cooling area, and added a washing system for degreasing as well as automated paint guns, which save on paint.

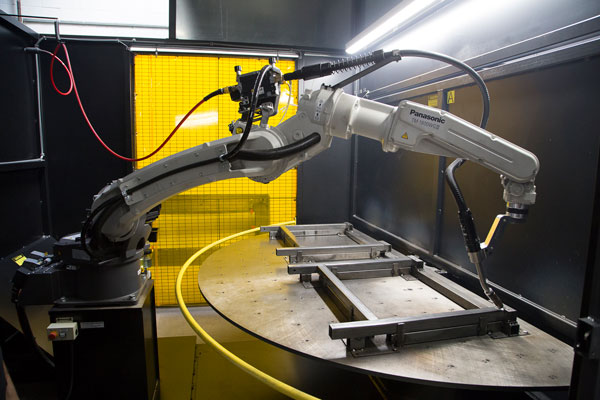

Calstone’s newest acquisition is a PerformArc robotic welder from Miller, which features a large work area where a six-kilogram robot welds a variety of parts. The robot has the production capacity of three human welders, meaning Calstone doesn’t need to hire as many temporary workers when it’s time to scale up for a big order.

Calstone’s robotic welder system from Miller. Photo: Sandra Strangemore

Another recent purchase was a 3D printer, which the company uses to develop prototypes for plastic components. “If you go to an injection moulding place, they aren’t going to make you one piece. They’re going to want 1,000 of something,” says Matt. “And if it’s off or wrong, you have to retool it and make another 1,000. So it’s a waste of money, product and time. With 3D printing, you can make two or three versions of something to see if it works. It’s been really cool to be able to do that.”

He says the increased automation has enhanced Calstone’s speed to market, which is attractive to e-retailers. The Calstone team works directly with its clients’ engineers on custom cart and workbench prototypes that can be turned around in as little as a week. The company has also been using SolidWorks 3D CAD software for simulations instead of shipping physical prototypes. “Since day one at Calstone, we’ve always been a custom special fabricator,” Matt says. “As we’ve grown, we’ve added machinery to be able to do that on a grander scale. We’re basically doing what we’ve always been doing, but in a larger volume.”

They’re doing it with a larger workforce, too – the Ecclestones have appointed an executive team, and hired a human resources manager who is developing an HR program. Workers who used to be general labourers now have titles specific to their roles, such as assembler or welder, which the Ecclestones say fosters accountability and transparency. Open positions are posted internally first to give workers the chance to learn new skills.

“All of the automation we’ve put in is not replacing jobs. We’ve actually added jobs,” Matt says. “A lot of the automation is just adding function to the company.” For example, programmers were required to operate the two new fibre-laser cutting machines, which were roles that previously did not exist at Calstone.

Changing the job roles has had a positive effect on the company. “You find people in your shop that you didn’t even know you had,” explains Matt. “A lot of our guys doing the programming now? They already worked here. And we didn’t even know they could do that.”

Calstone’s automated paint line. Photo: Sandra Strangemore

Strategies for sustainability

One of Calstone’s key differentiators is its unwavering commitment to sustainability – often by uncommon means – for which it has numerous awards. Among the recent honours: the manufacturer won the 2019 Pollinator Advocate Award for Canada from the North American Pollinator Protection Campaign for its work on a pollinator rain garden at Tom Longboat Junior Public School in Scarborough. In 2018, Calstone won the Partners in Project Green’s Green Business Award, which recognizes a company that exhibits leadership in transitioning to the clean economy.

“The environment is very important to us,” says Jamie. “Sustainability is in our DNA; it is in our company culture.”

Calstone’s sustainability story began small, with family patriarch Jim devising oft homemade, around-the-plant solutions to reuse energy and promote a cleaner, healthier work environment. Among Jim’s endeavours: hanging ivy plants on posts in the manufacturing facility to purify the air; modifying a unit to intake water heated by spot-welding equipment and blow it into the facility as a makeshift heat exchanger; installing air curtains at the loading docks of both buildings to trap heat; implementing an office-wide recycling program for things like printer inks; replacing all sprinkler heads and lightbulbs with energy-efficient options; and, developing a way to collect and recycle rainwater to water plants, flush toilets and cool equipment.

“We’re always looking at ways to save energy and heat the facility,” says Jamie. “Dad’s always inventing. He comes in every morning with a new idea.”

Jim’s rainwater solution was the brainchild for Calstone’s 2015 collaboration with Partners in Project Green, a Toronto-based promoter of eco-friendly business practices, to build a more complex rainwater harvesting system. Rainwater collected from the roof of the manufacturing facility is now diverted into a system of three outdoor ponds running alongside the building. When the ponds are full, the water starts to drain back into the water table. The rainwater is also collected and used to water all of the plants in the surrounding garden, which acts as an oasis for staff on their breaks. The pond system has since been recognized with a Clean 50 Project Award and an Ontario Nature Corporate Award.

Calstone’s outdoor break area is a rainwater collection system.

Photo: Sandra Strangemore

The company also operates a local “remanufacturing program,” whereby they accept returns from customers so they can recycle or reuse every piece rather than sending components to the landfill. All of Calstone’s products are GreenGuard certified, meaning they have been cleared of indoor air contaminants. Their manufacturing processes use environmentally friendly solvents and degreasing products.

The Ecclestones plan to implement another large-scale project at their distribution centre, but want to try something new. Since the building does not contain machinery that needs to be powered, they are looking at a solar project that would see panels installed on the building’s roof or walls. Bullfrog Power, a renewable energy source for green electricity, currently offsets the energy used for the office at the manufacturing facility – but Calstone’s goal is to generate and reuse its own power by 2025, so it can be completely off the grid.

“We’re very open to change, and to bettering ourselves, and to getting ahead of the curve,” says Jamie. “Going green is expensive, but we take that into account with all of our projects and how we’re manufacturing. We streamline other areas so that we can afford to be green certified.”

The Ecclestones at their eco-friendly manufacturing facility. From left: Matt, Jamie, Jim and Laura.

Photo: Sandra Strangemore

Game plan for growth

Becoming more self-sufficient is one of Calstone’s strategies for growth over the next five years. Up next, the company plans to purchase a panel bender, a second robotic welder, and robots to manage the input and output of materials in the fibre-laser cutting machine. Once their current tabletop supplier retires, Calstone plans to manufacture its own tops, which would mean more automation including a CNC machine and other equipment.

They’re looking at other uses for their products in the warehouse, and have been working with several robotics companies to develop new modular solutions, such as worktops for autonomous mobile robots used in pick-and-place or logistics applications.

“The great thing is, [our e-retailer clients] are working with us to try to develop those things,” says Matt. “They’re not just leaving us to work with someone else. They’re working with us to try and create the next version of what we’ve already made.”

The Ecclestones also plan to increase their market share in Europe over the next five years, adding to their burgeoning international client base in Brazil and Australia. “They’re willing to buy from Canada and the U.S. because even though there is a longer lead time, there’s so much positivity to buying from us, like fast turnaround and quality of product,” says Jamie. “It’s just a matter of managing our growth. We always want that family feel.”

A condensed version of this article originally ran in the September 2019 issue of Manufacturing AUTOMATION.

See more photos below!

Photos: Sandra Strangemore

Advertisement

- Ten Alberta steel producers receive $5.7M in federal funding for automation, jobs

- Surveys show China manufacturing demand weak amid trade war