Driving value through your manufacturing operations

June 10, 2016

By Ed Potoczak IQMS

A closed loop monitoring of equipment

A closed loop monitoring of equipment Jun. 10, 2016 – When it comes to IT resources, manufacturing departments are frequently treated like little brothers — getting hand-me-downs of computers, monitors, etc., when engineering, sales and other departments upgrade. That’s shortsighted considering how real-time insights into manufacturing operations can give organizations the agility to make decisions that contribute to profitability, customer loyalty, and business growth.

Still, too many companies look at manufacturing operations as a cost centre when they should be looking at how it can add value to the company. Clearly, if this dynamic is going to change, it will have to come from manufacturing teams showing how they can drive value for the organization. The following are three strategies to help a manufacturing plant build value for the company through the thoughtful and affordable application of technology.

1. Attract new customers, and grow existing ones

In most industries today, customers’ supplier selection criteria include a review of systems and processes to demonstrate sound advanced planning, operating efficiency, and the reliability of plant processes. To be competitive, manufacturers need to respond by providing not only a plant walk, but a very logical review of plans, performance measurements and systems that demonstrate the business is well organized and capable of being a strong partner.

Armed with a comprehensive manufacturing enterprise system, your team can give program managers clear insight into key plant operations to help build customer confidence that your company is and will be “launch ready” to take on their business. Ideally, the software includes integrated program management with timing charts, open issues, corrective action reports, and key performance indicators (KPIs) to address common customer questions about your manufacturing operations.

Of course, it is always simpler and less expensive to win new business from a satisfied customer who trusts you. However, additional business will come only if you have cultivated the current customers’ satisfaction and loyalty through your proven performance and outstanding responsiveness.

As a past sales executive, I know firsthand how important it is to start meetings with customer purchasing on a positive note. No one wants to begin an opportunity discussion by having to explain repeat issues — or worse, being surprised by a new problem that has not yet been reported in weekly or monthly summaries.

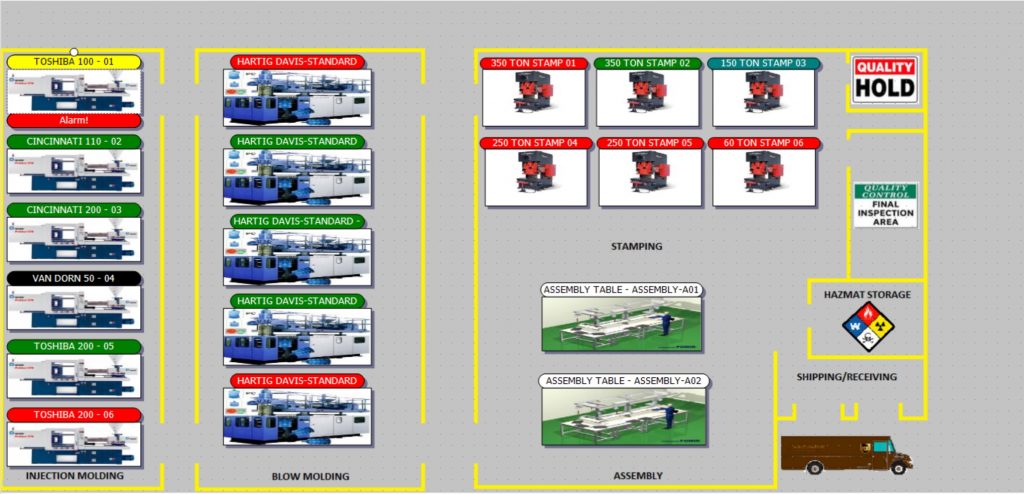

A powerful way to become a trusted partner for your customers is by leveraging investments in the automation of production equipment with real-time, integrated process monitoring and status reporting at the plant level. By integrating automated production data capture with statistical process control (SPC) tools and your manufacturing execution system (MES) and enterprise resource planning (ERP) software, you can prevent issues before they occur and affect customers. Moreover, closed loop monitoring of equipment, tooling and inspections ensures consistent quality and on-time delivery — giving customers the confidence that you are capable of performing as planned.

I think many of us would like to be the electronics and aerospace supplier that was able to report to customers a 75 per cent reduction in its time to react to manufacturing issues. By relying on monitoring, prevention and prediction instead of reaction, this company also was able to demonstrate to new and existing customers, alike, that it had a lights-out quality manufacturing system with strong uptime availability.

Your manufacturing team can achieve similar results with monitoring if you start with your end result in mind then apply technology very specifically to automate data capture and analysis. An added benefit of this wise investment is that your technical teams will have more time to focus on continuous improvement and innovation rather than reactive crisis management.

2. Increase capacity for new business

The numbers tell the story. A report by the Institute for Supply Management (ISM)* states that manufacturing companies currently operate at 81.6 per cent of normal capacity. This suggests an opportunity to grow the business by tapping that extra 18.4 per cent of available capacity. Yet many manufacturers cannot obtain the accurate view needed to identify availability for more jobs because they rely on simple spreadsheet models or mental juggling to calculate the capacity.

Instead, your manufacturing team should be taking advantage of modern production scheduling software that works in real time against real capacity constraints — allowing you to change priorities and automatically adjust for availability of approved operators, required tooling, and even scheduled downtime. The most advanced versions of this software can recalculate on the fly to show results in a matter of seconds, not hours or overnight.

The rollup of related information via production scheduling software instantly provides clarity, ensures the right level of inventory, and protects your plant’s ability to produce with or without your lone scheduling guru. In addition to driving revenues through new or bigger projects, the software also can drive significant savings. For example, one medical device components maker reported that scheduling improvements led to a 50 per cent reduction in scrap material and $36,000 annual savings in overtime costs.

Beyond scheduling software, manufacturers can maximize production capacity by directly integrating process line sensors and programmable logic controllers into their MES and ERP systems. Doing so provides an up-to-the-second view of the status of each work centre, process line, tool and instrument. This results in a shop-wide picture of the state of the entire production floor to assure that plans are being executed well. Importantly, this process data can be used to drive real-time analytics and alerts that support preventative and even predictive maintenance to minimize unplanned downtime.

There are systems available to capture production and process information manually and even automatically within a work centre — as seen on the controller’s human-machine interface (HMI). However, relying on operators to remember to manually enter counts, machine states, and process data is not going to deliver a consistent and timely status.

By optimizing the use of your equipment, your leadership will be clear on what business you can and should strategically pursue.

3. Deliver results at or above plan for executive management

In my past life as a program manager, it was always uncomfortable trying to explain the challenges in manufacturing operations without being perceived as “throwing someone under the bus.” That was especially true when I had to chase details spread over many files and software systems. By contrast, having accurate real-time metrics at my fingertips, I always was better prepared to explain both issues and achievements.

Integrating your ERP and MES systems with real-time process monitoring and status reporting will empower your manufacturing team with insights that maximize their ability to meet the cost, timing and profit goals set for them. It also provides the tools for accurately communicating with senior management to avoid surprises and build trust.

Implementing an integrated manufacturing enterprise system enables KPIs to be automatically rolled up without manual manipulation. As a result, the leadership team can spend their time analyzing trends and not bookkeeping issues. Meanwhile, boosting uptime, overall equipment effectiveness (OEE), and throughput of your assets increases cash on your balance sheet and boosts profits on the income statement. So, when it’s time for monthly financial reviews, the meetings can be efficient and positive.

Integrated insights also strengthen your position when customers demand price reductions during annual negotiations. Accurate information on actual labour and machine costs, enabled by automated production monitoring, along with an accurate picture of your quality and delivery performance as measured by your own enterprise system, will give your sales team the facts they need to hold the line and protect profit margins.

Last, by predicting and preventing quality issues before you produce a bad product, you can keep production costs in line with the estimated costs used by your controller from the quoted cost models. As a result, the company can meet the original cost estimates to maximize profitability and avoid absorbing extra costs that hurt the bottom line.

As you are planning the primary automation of new processes to speed production and reduce costs, be sure to close the feedback loop. Automate monitoring, and integrate the data directly into your MES and ERP systems so the resulting trend analyses can be your early warning system. In doing so, you will be positioned to deliver daily and monthly operating reports that consistently demonstrate value to your company.

***

Written by Ed Potoczak, industry manager at IQMS. He brings extensive expertise in manufacturing and engineering, and is certified in Design for Manufacture and Assembly and Value Analysis/Value Engineering.

*Source: Report issued by the Business Survey Committee of the Institute for Supply Management (ISM). December 8, 2015.

Advertisement

- French’s to bottle ketchup in Toronto by early 2017

- Ron Bullock of Bison Gear & Engineering passes away