WorldSkills countdown: Focus on mechatronics

August 27, 2009

By Manufacturing AUTOMATION

Only a week remains until 900 young apprentices make their appearance at the 40th vocational world championships, namely WorldSkills. WorldSkills will be hosted this time around in Calgary from September 1 to 6 2009. Today, we’ll focus on the largest competition discipline: mechatronics.

Only a week remains until 900 young apprentices make their appearance at the 40th vocational world championships, namely WorldSkills. WorldSkills will be hosted this time around in Calgary from September 1 to 6 2009. Today, we’ll focus on the largest competition discipline: mechatronics.

The Canadian mechatronics competitors – Andrew Marcolin and Jamie Feenstra – secured their positions at the 2008 Skills Canada competition held in Calgary. Graduates of the Mechatronics and Mechanical Engineering Technology program at St. Clair College, they were also awarded gold medals at the regional, provincial and national competitions in 2007. (For a review of Canada’s participation in the event, read “Oh, Canada: Countdown to WorldSkills Calgary 2009.”)

Along with teams from 30 other nations, Marcolin and Feenstra will compete in this key discipline for the technologies of the future, in hopes of taking home the gold medal for their country.”

In teams of two each, the apprentices are required to construct actual mechatronic systems at the competition, place them into service and program them, as well as optimize and service them. The challenge: The participants are only fully familiar with one part of the task. The mechatronics teams are not made aware of the largest portion of the problem to be solved until the beginning of the respective competition day.

“This is the best way for a young mechatronics technician to prepare for actual situations in day-to-day work. When I drive to a customer, I don’t find out exactly what he wants, and how a machine is supposed to be optimized or a system reprogrammed, until I’m actually on location. You have to be highly flexible in this job, and always be ready to adjust to new circumstances,” explains Andreas Veil, runner-up at the 2005 WorldSkills.

Competence instead of drilling

Competence instead of drilling

Demands placed upon apprentices have increased over the years. Sybille Bohland, mechatronics trainer at Festo, reports: “When the mechatronics championships first started, each team knew exactly what would await them at the competition. The tendency was to drill the participants. This was not the approach the WorldSkills committee wanted to take. Not learning by rote, but rather genuine interdisciplinary thinking – involving electronics, mechanics and IT – should distinguish a mechatronics technician, i.e. the ability to find ideal solutions to complex problems quickly. For this reason, the contestants have to find their own way: from workstation layout and organization right on up to the actual solution, they decide everything on their own. Only the results are predetermined.”

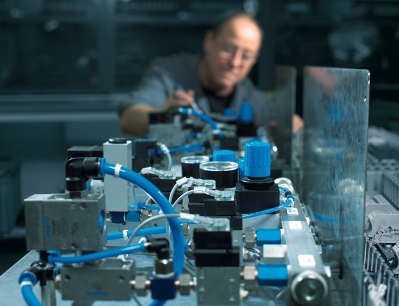

A practical orientation is thus top priority at the mechatronics competition. MPS stations from Festo Didactic make it possible. The modular production system offers realistic learning conditions for mechatronics technicians and other related vocations, and thus prepares apprentices ideally for the demands which will be placed upon them in professional life.

“In addition to technical competence, work oriented learning at MPS stations also promotes soft skills such as independence and team spirit,” explains Michael Linn, product manager at Festo Didactic. At the national competition, the MPS system also provides the contestants with the opportunity of demonstrating peak performance under circumstances which come very close to actual industrial conditions.

Innovation begins with qualification

Festo initiated competition in mechatronics 17 years ago, and took over sponsorship of WorldSkills Mechatronics. The company supports Skills Canada, and SkillsGermany at the Hanover Trade Fair, the world’s largest industrial exhibition, in the disciplines of mechatronics and mobile robotics.

Valuable impetus for vocational training is spawned, business contacts are established and trends for new developments are recognized at WorldSkills. The goal of the vocational world championships is the continuous up-grading and promotion of training and vocational education. Promoting young apprentices and inspiring them for technology is an important task for the company.

“Education, innovation and technology are the key factors for further expanding our technological peak performance. Education is not only the responsibility of the government. And this is particularly true in the case of future oriented vocations. For this reason, Festo supports top performance in the areas of training and international educational standards by means of national and international projects such as SkillsGermany and WorldSkills Mechatronics,” explains Dr. Eberhard Veit, chairman of the board of directors and director of technology and market positioning at Festo AG.

Coming soon: In the mobile robotics competition, 14 international teams will compete against each other. Team Canada’s Mobile Robotics competitors are represented by Pavlo Tovaryanskyy and Myles Robinson, of Technical Vocational High School in Winnipeg, Manitoba, and were gold medal winners of robotics in both the provincial and national skills competitions in 2008.