Emerson debuts micro laser welder for manufacture of delicate parts

June 26, 2020

By Manufacturing AUTOMATION

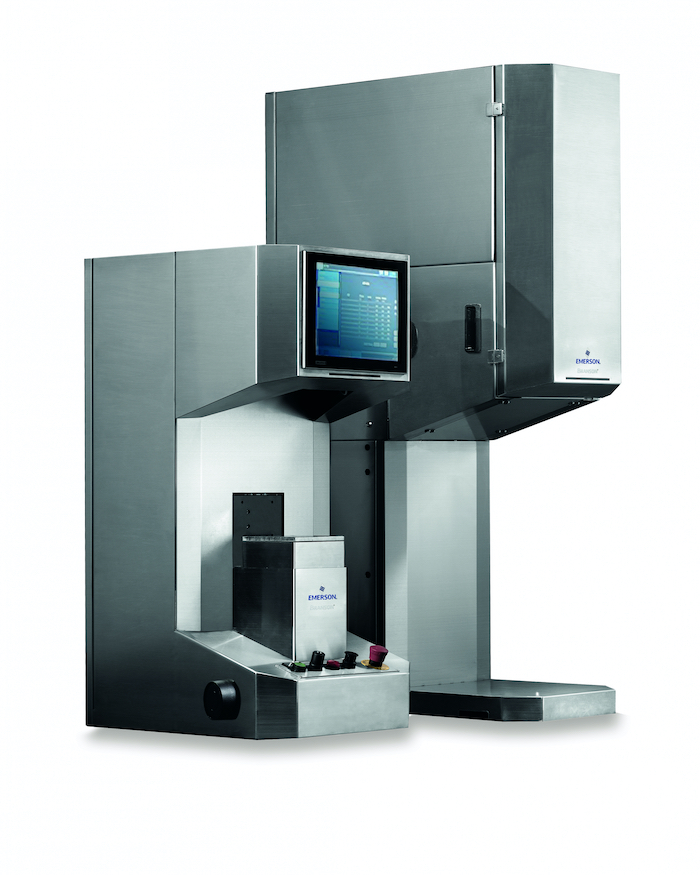

Emerson has introduced the Branson GLX Micro Laser Welder for the manufacturing of delicate plastic parts used in the medical and consumer electronics industries.

The bench-top version of the GLX Series uses advanced laser technology and low clamp force to produce precise, clean and repeatable welds.

The GLX Micro uses the patented Simultaneous Through-Transmission Infrared (STTlr) laser welding technology, which means all lasers are fired simultaneously to heat, melt and bond the component parts along the entire weld surface in 0.5 to five seconds, depending on material and geometric complexity.

This method is highly repeatable and stable, which the company says can increase production throughput.

STTlr eliminates the use of friction that may generate flash and particulates, thereby ensuring smooth and barely visible weld lines can be incorporated into product designs.

With STTlr, highly complex 3D contours can be accommodated, allowing designers to create parts for maximum functionality and ergonomic appeal. The GLX-micro offers a clamp force of 1 Newton, enabling the joining of small and very delicate parts, including those with embedded electronics and sensors.

The GLX Micro is cleanroom-compatible with a stainless-steel design and requires no lubricants. It is powered from a remote electrical cabinet that can be positioned outside the production area.

To support traceability, production data – including weld depth and clamp force – is available in a range of formats and can be outputted to the manufacturing execution system.

Advertisement

- Building a bot: Ontario students develop robot design for competition

- NGen launches $30M challenge to develop strategic supply capabilities