Canadian manufacturers hope to extract maximum benefits from ERP, as per MA poll

March 3, 2023

By

Sukanya Ray Ghosh

For the Canadian manufacturing industry, digital transformation is not a novel concept. All industry stakeholders understand that enterprise resource planning (ERP) solutions are a major part of the digital transformation journeys that have the potential to take their businesses to the next level.

ERP trends and advancements in recent years reflect the evolution of the digital world. The goal is to leverage this space to extract maximum benefits from ERP implementation in a manufacturing setting.

What manufacturers want

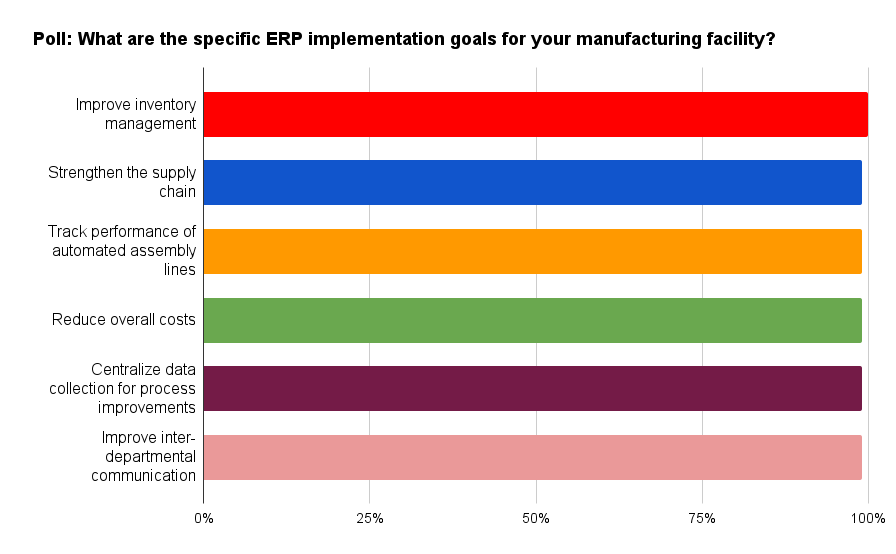

In a recent Manufacturing AUTOMATION website poll, Canadian manufacturers shared what they hope to achieve with ERP implementation at their facilities. Given the option of selecting multiple goals, the poll produced a very interesting result.

Most respondents hoped to leverage ERP as much as possible and extract all possible benefits from the implementation.

All respondents wished to improve inventory management at their facilities. When demand is high, being able to have full control of in-house inventory is essential to stay competitive. It can be a major differentiation for successful businesses.

Strengthening the supply is another benefit that manufacturers hope to achieve from ERP solutions, as indicated by 99 percent of the respondents. Discrete manufacturers often rely on complex supply chains involving multiple suppliers, vendors, and distributors. ERP systems provide real-time visibility into the supply chain, enabling better demand forecasting, inventory management, and procurement.

Ninety-nine percent of the respondents also indicated they wish to track the performance of the automated assembly lines at their manufacturing facilities. Predictive maintenance of automated machines allows manufacturers to avoid expensive downtimes, while also maximizing equipment efficiency.

In addition, 99 percent of respondents wish to reduce overall costs, centralize data collection for process improvements and improve inter-departmental communication. ERP systems generate a wealth of data about various aspects of manufacturing operations. Advanced analytics and reporting capabilities within ERP platforms allow manufacturers to gain valuable insights into performance metrics, production trends customer behaviour and more. It is also not a surprise that manufacturers are targeting cost reduction through their ERP implementation. In the current market conditions, balancing costs has become a pain point for many. Enhanced inter-departmental communication can clean up operational bottlenecks and speed up critical decision-making.

The latest trends in ERP

- Cloud computing has gained significant traction in recent years. Cloud-based ERP solutions are on the rise. Cloud ERP offers benefits such as scalability, accessibility from anywhere, reduced upfront costs, automatic software updates, and improved data security. It allows manufacturers to leverage the power of ERP without heavy infrastructure investments.

- In a world where smartphones and tablets rule, it is no surprise that mobile ERP solutions are also trending. Today, data is power and having the ability to access real-time data on the go is highly sought-after. Mobile ERP applications allow manufacturers to access real-time data, collaborate with team members, monitor production processes and make informed decisions. They offer a high level of flexibility in the midst of extremely busy schedules.

- The integration of IoT devices with ERP systems is another potential that manufacturers can tap into. IoT sensors embedded in equipment, machines and products collect real-time data, which is then integrated with ERP systems. This integration enables proactive maintenance, real-time asset tracking, predictive analytics, and better visibility into production processes.

- Artificial intelligence (AI) and machine learning (ML) technologies are being integrated into ERP systems today to improve decision-making, automate repetitive tasks and enable predictive analytics. For discrete manufacturers, AI and ML can help optimize production scheduling, forecast demand more accurately, automate quality control, and enhance supply chain management.

- ERP systems today are incorporating advanced analytics and business intelligence capabilities, allowing manufacturers to gain deeper insights into their operations. They are able to leverage data visualization, dashboards and predictive analytics tools to gain actionable insights from their ERP data. With these solutions, manufacturers hope to do demand planning, forecasting, risk management and performance tracking. Eventually, this helps them make informed decisions and influence outcomes accordingly.

- Discrete manufacturers collaborate with external partners, suppliers and customers on a regular basis. The ERP systems of today are designed to integrate seamlessly with external systems such as customer relationship management (CRM), supplier management, e-commerce platforms and logistics providers. This kind of integration allows businesses to streamline data exchange, facilitate information sharing and enhance supply chain visibility and collaboration.

Advertisement

- Rockwell Automation acquires digital technology company Knowledge Lens

- ATS acquires Thailand-based systems integrator ZI-ARGUS