HARTING makes headway on single-pair Ethernet, energy storage

February 5, 2021

By Manufacturing AUTOMATION

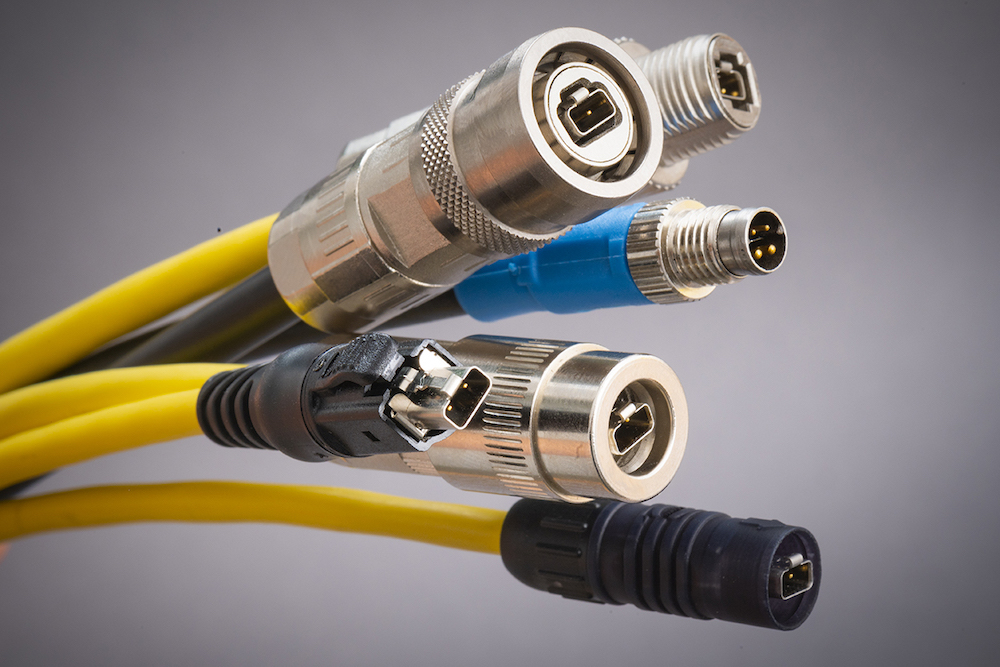

HARTING T1 connectors. Photo: HARTING Technology Group

HARTING T1 connectors. Photo: HARTING Technology Group Devices using HARTING Technology Group’s single-pair Ethernet technology are expected to be on the market by the end of 2021, said experts at the company’s digital press event this week.

On Feb. 2, the company highlighted the global developments and Americas-specific solutions it has made in several sectors, including industrial automation and energy and data centre infrastructure.

HARTING emphasized how the global social trends of demographic change, (de)globalization and sustainability result in technology trends such as modularization, autonomy and digital twins.

With connectivity being backbone to future industrial technologies, DC power supply in industry and new ecosystems such as Single Pair Ethernet (SPE) in the field of industrial communications will play critical roles in advancing automation, the company said.

Here are the highlights from the event:

Ethernet becomes critical

Ethernet has become a critical communication standard in industrial automation. With rising transmission rates, space-saving infrastructure and new physical layers such as single-pair Ethernet, IP-based networks are now also conquering the last remaining field-level areas.

HARTING Americas SPE Lead, McKenzie Reed, provided an update on local SPE developments starting in early 2020, when HARTING announced single-pair Ethernet at the SPE Symposium.

Following, HARTING Americas launched an IP20 version of the T1 connector, the standard mating face for industrial single-pair Ethernet. In 2020, HARTING also founded the SPE Industrial Partner Network and joined as a principal board member of ODVA, where the company helped to develop the standard for industrial single-pair Ethernet.

In partnership with ODVA, HARTING plans additional single-pair Ethernet product launches and projects in 2021. HARTING is currently seeing early proof-of-concepts using SPE connectors, cables and unmanaged Ethernet switches.

“We expect to see real devices utilizing HARTING SPE in the market as soon as the end of calendar year 2021,” Reed said.

Developments in energy storage

The energy storage market has evolved extremely quickly over the last few years. Global focus on the environmental footprint has given overall developments an additional boost.

Sustainable use of renewable energies can only be achieved through energy storage systems, as they enable time-delayed, demand-oriented use of the power produced by renewable energy.

Connectors speed up the assembly and operation of energy storage systems based on battery modules. HARTING’s Han S connector concept offers a solution for the front wiring of energy storage systems, for example.

Joint engineering with partners

Developing solutions in partnership is one of the core competencies of HARTING Customized Solutions and can take place in a wide variety of areas of industry, including integration in power supply units for decentralized drive technology.

Cory Jenkins, director of product management for HARTING Customized Solutions in the Americas, provided an update on the local subsidiaries recent successes, highlighting the company’s “in the region, for the region strategy” that positions it to support local markets.

One such success was with a large agricultural OEM, with whom HARTING was able to offer electrification technology. HARTING’s team was able to marry their product development with the OEM’s roadmap.

Jenkins also identified machinery as a key market for HARTING, specifically in the design of customized M8/M12 cordsets. “We see our customers as our partners. We like to get to know their engineering teams and work together to bring new technologies to the market,” he said.

Developing specifications for Power Shelf

Will Stewart, senior industry segment manager, gave an update on how HARTING is supporting the data centre market, a key industry especially in these unprecedented times.

HARTING has been a partner for the enterprise data centre companies for several years. Starting in 2016 with Microsoft’s Project Olympus, HARTING helped Microsoft simplify global supply chain and untangle a diverse web of power architectures that were used across the globe.

Microsoft partnered with HARTING to develop a universal power distribution unit that could be used anywhere in the world, using HARTING’s Han-Eco for its size and ruggedness, to significantly shorten data centre deployment times.

HARTING announced that it is leading the development as lead author on the specification on the Power Shelf inside the Open Rack. “The design has been completed, and we expect that Open Rack version three will launch in early 2022,” Stewart said.

Partnership with MIT tackles IIoT

Dr. Vivek Dave explained how HARTING and MIT are working together to address four challenges faced when trying to apply machine learning to industrial environments.

Such challenges include: smaller data sets than other industries, complex processes that may change over time, and the challenge in capturing and translating human expertise into something a machine can overcome. Dave praised the work HARTING and MIT have done so far and underlined the importance of this partnership.

“Our partnership with MIT has allowed us to build on HARTING’s legacy of innovation and streamline the digital journey going from electrons to actionable insights to our customers,” Dave said. “The entire premise of industrial Internet is this journey from raw data to actionable insight.”

Advertisement

- Ford to cut back F-150 production due to chip shortage

- Industrial Internet Consortium launches supply network test-drive program