Improving your order-processing technologies

May 27, 2015

By Brent Halverson ecmarket

Change how you process sales orders, not how customers order from you

May 26, 2015 – Today, companies are continuously looking for ways to introduce order-processing technologies designed to improve inefficiencies.

When your company’s client base spans across the globe, it is not uncommon that you run into discrepancies in aligning your new technologies with existing customer’s business operations.

The challenge lies in having the capacity to convert customers towards using technologies, like electronic data interchange (EDI), to better support your capabilities in working alongside them, while also improving your own efficient operations. Sometimes, this is an easy sell. Collaborating on options to better serve your customers means faster and more reliable service and sets up a ‘win-win’ situation. However, not all customers are financially equipped or have access to improving or implementing these technologies. How do you keep customers up-to-date with your newly implemented order processing procedures without compromising your current business processes with them?

This was the case for 3M. The company operates in 65 countries, employing more than 80,000 people. Collaborative efforts of efficiency are key to a smooth execution of operations and customer satisfaction. With their customers spanning globally, sales orders are coming in at a steady pace daily. While they want to implement further measures to improve current inbound order processing, many of their current customers face the barriers of funding and access to resources to implement EDI.

As manufacturers, sales order processing is an area where efficiency and accuracy measure high in importance. By improving their sales order entry processes, 3M would be able to improve productivity and ultimately, better serve their customers. 3M looked to find a solution that improved their inbound sales order processing without interrupting their customers’ existing business processes where EDI implementation is not possible.

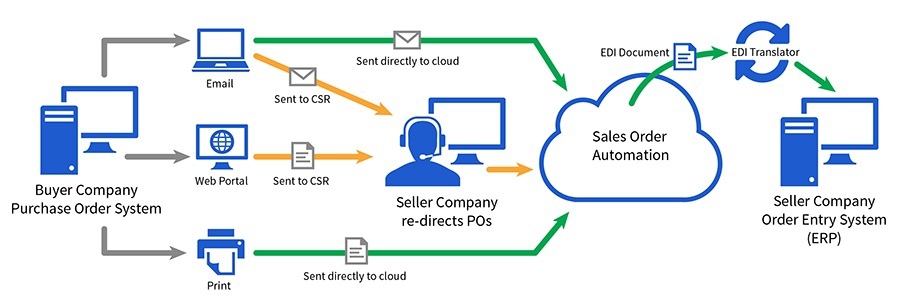

After the evaluation of many technology solutions, like OCR, 3M decided to implement Conexiom’s sales order automation. Sales order automation provides the convenience of eliminating the time-consuming task of manual entry allowing employees to focus on customer service, without having customers alter or convert their current business procedures. 3M used the technology offered by Conexiom that allowed for the easy adaption towards electronic ordering and worked with the existing enterprise resource planning (ERP) systems.

Ian Hardgrove, executive vice-president of sales and marketing at 3M, states that “By eliminating manual order entry we can reduce errors, expedite order processing and at the same time improve our service levels and customer satisfaction.”

With sales order automation, orders sent into 3M, whether it be through fax or email, are seamlessly transformed into sales orders and to EDI orders, completely eliminating error and manual entry. 3M reported benefiting from incorporating sales order automation into their business process, namely: productivity, better customer service, cost efficiency and quick ROI.

Manufacturers are able to add a new level of flexibility that differentiates them from other competitors through investing in sales order automation. Companies have the option of increasing capacity to take on higher demands without increasing staff, or having to change the way they do business.

—

As president and CEO, Brent Halverson leads the overall strategic direction of ecmarket and is responsible for developing the business plan and driving success in all areas of the business including product, finance, support, services, sales, and operations.

Advertisement

- IMP Aerostructures lays off 30 workers in N.S. plant

- Atlantic Canada’s food processing hit hard by consolidation: report