Keeping the lights on: Pandemic underscores need for cloud-based systems

December 10, 2020

By

Kristina Urquhart

With new reports indicating Canadian manufacturers are not reaching the full potential of their cloud investments, identifying a sound strategy is more crucial than ever

Photo: Gremlin/Getty Images

Photo: Gremlin/Getty Images Cloud-based services have enabled rapid pivoting for manufacturers throughout the course of the COVID-19 pandemic, allowing them to quickly deploy production and supply chain adjustments – that is, if they already had a successful implementation of the technology in place.

For those that didn’t, the pandemic has stressed the importance of off-premises solutions – not just for remote working, but to improve processes across the value chain. In the recent article “Making the Cloud Pay,” McKinsey & Company highlights R&D, procurement, manufacturing, supply chain and sales as just some of the areas that the cloud can benefit.

According a McKinsey survey of 750 respondents, company leaders face two diametrically opposed factors when it comes to the cloud. First, company leaders who already employ a cloud-based solution estimate that 30 per cent of their total spend is wasted on ill-advised solutions. Second, leaders expect to increase their spending on cloud initiatives by 47 per cent in 2021 in order to keep up with the marketplace.

With respondents reporting that 23 per cent of their cloud investments go over budget, the McKinsey authors identify several reasons why costs can balloon. Among them: applications that are too complex, time-and-materials models over as-a-service models, and hidden costs that come from add-on services or the company not fully understanding the technology.

Identifying business value

On Dec. 3, Accenture released a similar study on maximizing cloud value that surveyed 750 senior leaders and IT professionals at large enterprises in 17 countries, including Canada. Just 34 per cent of Canadian companies reported they are reaching the full value they expected on their cloud investments, compared to 37 per cent globally.

“The reality is that not every company is unlocking the full potential value of the cloud, ” says Jennifer Jackson, managing director and technology lead in Canada at Accenture, in a statement.

The cloud “really levels the playing field,” says Foster. “When you take what a cloud provider can give you as far as computing power and data storage – no longer are those things just for the large companies and enterprises that have massive amount of resources.”

“Our newest report shows a surprisingly small two-year improvement in returns on corporate cloud initiatives, suggesting that a more thoughtful and holistic approach is needed. Competing in the age of COVID-19 and beyond requires that companies implement a cloud-first strategy, in which every element of their business leverages the power of the cloud.”

Jerry Foster, chief technology officer at Plex Systems, a provider of cloud-based smart manufacturing software, agrees that there is often a disconnect between what companies want and what they eventually get.

“Customers are kind of excited about the next shiny thing, the new technology and they’re actually not sitting down to do the correlation of, ‘how does this relate to the business value?’ Or, ‘what’s the ROI that I need?’” he says. “What’s the business case that you want to solve? That’s really important.”

Manufacturing in the cloud

The cloud-based smart manufacturing platform from Plex Systems was designed specifically for manufacturers, incorporating enterprise resource planning (ERP), manufacturing execution systems (MES), quality control and supply chain planning for a number of industries, including aerospace, automotive, food and beverage, electronics, plastics and rubber, and precision metal forming, among others.

The Michigan-based company was a cloud pioneer, founded in 1995 within MSP Industries Corporation, a forging company. By 2001, Plex was offering software-as-a-service. Now the software is deployed in 37 countries including Canada, and in over 1,200 facilities, processing over eight billion transactions (such as barcode scans, moved inventory, etc.) a day.

“Plex was actually born right on the shop floor next to the operators and the forklift drivers and the foremen and women,” says Foster. “So we can provide all those capabilities from the shop floor–centric view.”

How it works

Using data collected from PLCs, sensors and other industrial devices – all connected via secure protocols – the Plex platform connects machines, systems and operators in the plant with real-time information.

The software automates processes from job scheduling to inventory management to error proofing, and, powered by the Industrial IoT (IIoT), analyzes the data produced by each.

Insights are then generated that can help manufacturers identify inefficient operations, high scrap costs, inaccurate inventory, lack of material traceability/supply chain visibility and limited production control.

While Plex’s smart manufacturing platform has a wide range of features, the SaaS is modular – so users can start with just one piece, like the MES or ERP, and add more capabilities as required.

“One of great things about cloud software [is] getting those functions into our customers’ hands,” Foster says. “Once they start using it and see how easy it is, it’s seamless to add new modules or new functionality or to expand significantly across individual plants, or even across the enterprise itself.”

Benefits of the cloud

In addition to enabling growth, the McKinsey & Company study cited reduced costs over time as one of the main benefits to cloud-based services.

The cloud can automate business processes such as procurement, allowing for identification of sales opportunities or the building of quotes, and lead to efficiencies in the IT department, whether staffing or lower spend on hardware.

Just 34 per cent of Canadian companies in a recent Accenture study reported they are reaching the full value they expected on their cloud investments, compared to 37 per cent globally.

Subscription costs can also be added to a company’s operational budget instead of its capital budget, which can fluctuate in times of crisis.

The cloud “really levels the playing field,” says Foster. “When you take what a cloud provider can give you as far as computing power and data storage – no longer are those things just for the large companies and enterprises that have massive amount of resources.”

Visibility during COVID-19

And, as evidenced by the events of the past year, cloud-based services are what enable remote working.

Foster says that when widespread shutdowns were first ordered to combat COVID-19 in late March, Plex’s customers were able to keep running with minimal disruption thanks to their cloud-based systems.

“The facilities that don’t use cloud software – when the pandemic hit, they had to shut down. They basically went dark,” he says. “They just didn’t know what was happening inside the facility, as opposed to the ones that had the visibility no matter where they were.”

The companies that did keep the lights on were then able to continue producing their essential goods, or retool to make hand sanitizers, PPE, masks, face shields and parts for ventilators.

Deploying on the go

“All that COVID-19 has done is highlighted the need for cloud-based software and why it’s so important,” Foster says. “Being in the cloud really provides what I would call an innovation platform. When you’re part of a cloud-based software community, the things that are being built into the software and delivered just inherently become part of [your] software.”

For example, as manufacturers were still dealing with COVID-related bottlenecking issues in the summer of 2020, the Plex team added the ability to enter a negative event into its supply chain planning system to “help offset the anomalies that [companies] were seeing, because we didn’t want that to change their planning for next year or the next few months,” Foster says.

“The cool thing was, once we provided that and built that into the software, it was just automatically delivered and deployed to the users. They didn’t have to install it, download anything, or have IT come and put it in place. Those innovations happen naturally and seamlessly.”

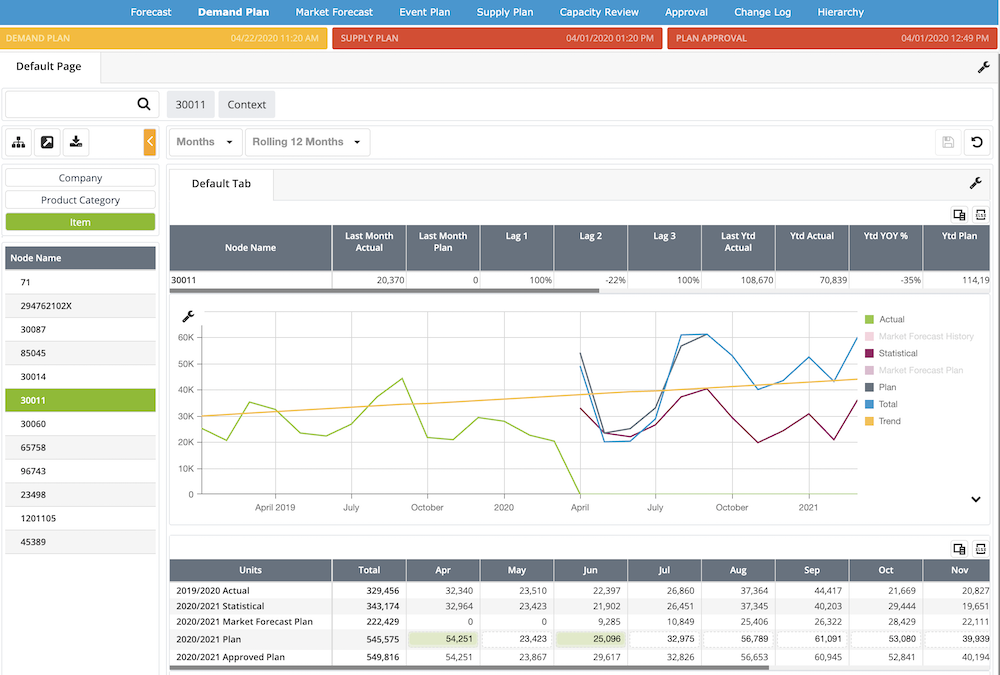

Plex’s Market Forecast Manager uses internal and external data along with demand plans to encourage more accurate inventory decision. Photo: Plex

Creating a new community

The SaaS model also makes it easier for companies to collaborate – and commiserate. In the spring, Plex built a COVID-19 resource centre for its global clients that aggregated their production data, so that operators could check in to see how their counterparts across the rest of the world were doing.

“There’s lots of speculation and lots of talk in the press and from the pundits on what were the actual effects of COVID on manufacturing, but we could see real-time what was happening to production across all of our customers around the world,” explains Foster.

“The facilities that don’t use cloud software – when the pandemic hit, they had to shut down. They basically went dark,” he says. “They just didn’t know what was happening inside the facility, as opposed to the ones that had the visibility no matter where they were.”

In April, that had translated to a 95 per cent global drop in production. Over the following months, factory outputs slowly started to creep up again. By the time of MA’s interview with Plex Systems in October, the company’s Canadian customers – which account for about five per cent of Plex’s total clients – had surpassed their pre-pandemic production rates.

Foster credits the cloud for helping with the relatively fast rebound. “It’s been really cool watching it and seeing that happen live, and being able to give advice and give confidence to our manufacturing customers on what’s happening.”

Overcoming challenges

Both the Accenture and the McKinsey & Company studies identified the skills gap, current equipment capabilities and security as top concerns of both high and low cloud adopters.

Not having enough staff that understands how the cloud operates was a concern for 58 per cent of respondents in the McKinsey report. The burden of security requirements and compliance constraints clocked in at 52 per cent.

Foster wants to debunk the myth that cloud-based software is less secure than any other option out there. “I often tell our potential customers that if you want a secure system, cloud-based is the way to go because we have been doing this and rooting out all the insecurities for years,” he says.

“We have to dispel this notion that just because you’re not connected to the internet or because you’re not using cloud software, that you’re not exposed [to risk]. So many of those breaches happen internally – bad actors inside the four walls, or people coming in with their USB drives or their own devices. Those sorts of things are extremely prevalent. There’s a huge risk there.”

Developing a cloud strategy

Finding a technology vendor that is stringent about security is a first step to developing a cloud strategy for your business.

The authors of the Accenture study offer several other takeaways for decision-makers: use business cases to identify revenue and cost efficiency opportunities, implement talent training and change management programs to get staff on board, and ensure technology partners offer valuable skills to the organization that will help to keep costs down.

Above all, the C-suite must recognize the impact that technology implementation has on employees, because it may be the difference between a successful implementation and an unsuccessful one, Foster says.

“Leading them through that as partners, and as engaged participants in installing and deploying new technology – whether it’s cloud-based software or any other technology that you’re putting in place – is so crucial.”

Advertisement

- Rittal Canada announces new president

- Auto sector slow to hire back in the third quarter as manufacturers lagged