Automated system helps B.C. chip manufacturer deliver more consistent flavour

March 26, 2017

By tna

Mar. 26, 2017 – Chip manufacturer Naturally Homegrown Foods has been able to improve application consistency, reduce waste and simplify cleaning operations by installing a new seasoning system from integrated food processing and packaging equipment provider tna.

The investment, it says, has enabled Naturally Homegrown Foods to deliver consistent coverage and flavour for its potato chip brand, Hardbite Chips, by replacing an out-of-date steel coating drum and dry powder applicator with an efficient automated system.

Based in Maple Ridge, B.C., Naturally Homegrown Foods specializes in the production of high quality batch-fried chips and supplies retail locations in Canada, the U.S. and Asia. With each batch of chips hand-cooked, every chip is created using the finest and freshest ingredients to deliver unbeatable taste. To meet growing demand, the company needed a flexible seasoning solution that ensured consistent and efficient application of eight different dry seasonings, with minimum machine downtime between flavour changes. In addition, the new system had to integrate and work seamlessly alongside other processing machinery in the facility.

Improved flavour consistency

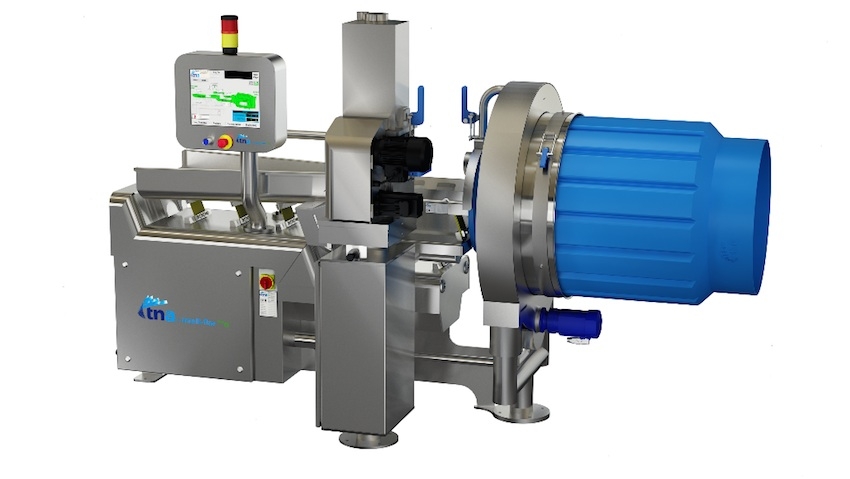

Flavour is often considered key to best-selling snack products, ultimately influencing product purchase in terms of consumer satisfaction and acceptance. With a primary objective to improve overall product consistency, Naturally Homegrown Foods installed the tna intelli-flav OMS 5 seasoning system to ensure uniformity for every chip produced. A perfect solution for the Hardbite range, the tna intelli-flav OMS 5 features a responsive variable mass seasoning system with dynamic vibratory weigher to directly control powder application from the drum. This enables a proportional amount of seasoning to be consistently applied to the product for improved coverage and flavour dispersion — even for products with irregular surfaces, including batch-fried chips.

“Here at Naturally Homegrown Foods, we have an unwavering desire to create the best potato chip out there, with each pack of Hardbite Chips dressed in aromatic, natural seasonings. Delivering unrivalled product quality is therefore a top priority for us,” commented Kirk Homenick, president at Naturally Homegrown Foods. “We’ve seen a vast improvement in seasoning consistency as a result of installing the tna intelli-flav OMS 5 – most notably, we’ve been able to reduce our seasoning application rate from 8 to 9 per cent down to 5 to 6 per cent.”

Further performance benefits are realized through the positioning of the scarfplate on the tna intelli-flav OMS 5 infeed. Positioned closer to the top of the tumbling product, the scarf adds dry powder into the flavouring area more accurately, providing high quality, consistent seasoning.

“The addition of this equipment has made such a difference for our facility compared to the older screw auger feature in our previous system,” noted Homenick.

In addition, the scallop-designed infeed conveyor curves to match the shape of the drum which reduces product drop, helps control product direction and results in reduced product waste.

Ultimate flexibility

Rapidly changing consumer demands have increased pressure on snack manufacturers to run a variety of capacities, package sizes and materials within their plant.

Teri Johnson, regional sales manager at tna, explained, “To increase their product portfolio at minimum cost, food manufacturers are increasingly looking for more flexibility in their existing production lines to customize their offering and respond to shifts in consumer demand and preferences. Manufacturers adding new flavours to their product range, for example, will require a system that allows for quick product and flavour change and outputs to be adjusted according to demand.”

With the Hardbite Chips range including eight different flavour profiles, Naturally Homegrown Foods required a seasoning system that offered rapid cleaning time for flavour changes and minimum downtime. The tna intelli-flav OMS 5 has a simple modular design that is fully enclosed to help prevent seasoning, dirt and other materials from building up, thus allowing for increased levels of hygiene and ease of cleaning. In addition, the system’s pivoting drum provides accessibility for hard to reach areas, simplifying day-to-day operations.

“As a small plant that is experiencing growing demand, it’s imperative that seasoning changeovers and cleaning downtime is kept to a minimum to ensure optimum production levels. Since the tna intelli-flav OMS 5 was installed, changeover times have been reduced by 15 to 20 per cent. Now we are able carry out a seasoning changeover in less than 20 minutes thanks to the system’s simple design,” added Homenick.

Looking ahead

“The entire installation was completed quickly and on target to prevent interrupting production during a time of high demand. Once in place, the system basically behaved as a plug in and play,” said Homenick. “tna has a great reputation in the marketplace and we were impressed with the level of service and flexibility in system design. They were able to deliver a solution that addressed all of our needs on quality and controls, with the necessary support. We have been greatly appreciative of the tna intelli-flav OMS 5 system and what it brings to our operations – the seasoning system has delivered on our key objectives of improving overall consistency and seasoning application. It has equally supported our growth and helped us achieve increased household penetration of the Hardbite brand, by allowing us to produce a highly consistent product.”

Also commenting on the installation, Johnson added, “We are delighted to partner with Naturally Homegrown Foods to help make their production line more efficient and support them during this exciting time of growth. Our technical expertise and dedication to customer service gives us the opportunity to create and supply innovative products to our customers worldwide offering start-to-finish solutions for the entire production line.”

Advertisement

- West Liberty Foods saves $2M in maintenance costs with Lean manufacturing solution

- Ferretti selects Siemens software to optimize yacht design and production