PPE manufacturer launches medical mask automation and vision systems

March 16, 2021

By Manufacturing AUTOMATION

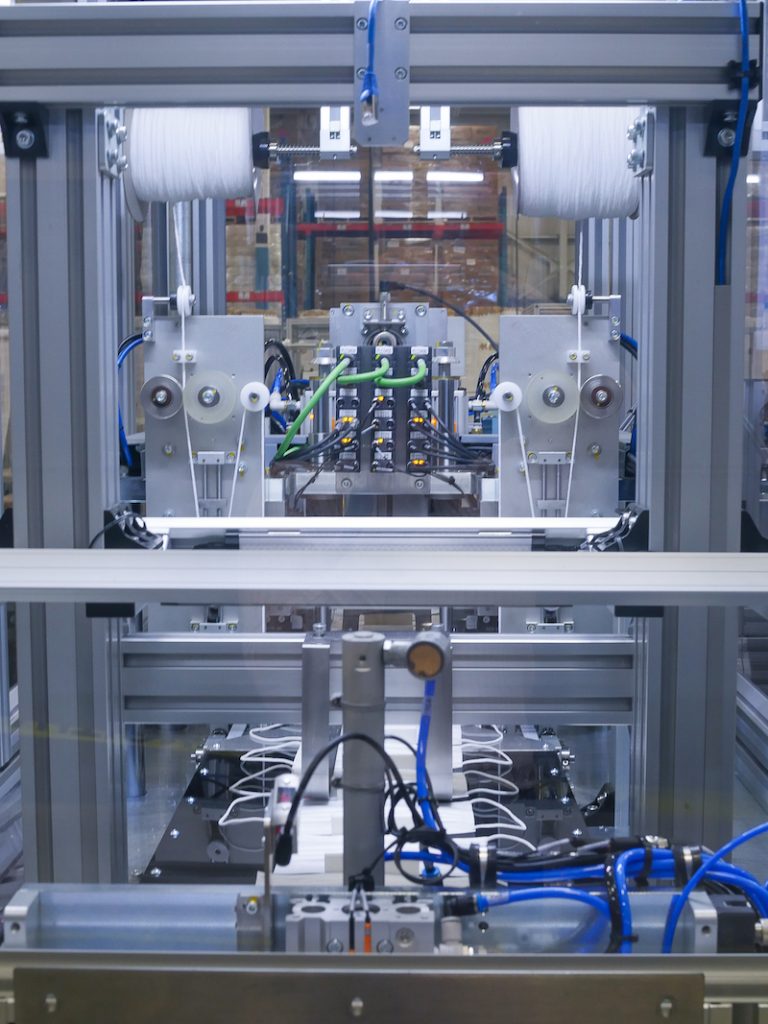

Medical mask manufacturing automation system. Photo: The Canadian Shield

Medical mask manufacturing automation system. Photo: The Canadian Shield The Canadian Shield has launched newly designed, made-in-Canada medical mask automation and vision systems.

The technology enables The Canadian Shield, a Waterloo, Ont.–based PPE manufacturer, to compete with overseas companies, and sell their turnkey medical mask manufacturing lines and vision systems to other producers around the world to improve their operations.

Born out of the COVID-19 crisis, The Canadian Shield quickly scaled its team and built strategic partnerships with several local automation companies. These partnerships have helped to rapidly design new technologies and optimize automation solutions for global sale.

In March 2020, Canada and other nations around the world faced the harsh reality of being dependent on global supply chains for critical pandemic supplies.

As a result, countries across the globe have invested in domestic PPE manufacturing capacity to ensure supply and production capabilities in the event of future crises.

The manufacturing machinery required for producing personal protective equipment, like medical masks themselves, were previously made almost exclusively in countries like China and Malaysia.

These countries have different electrical, safety and quality standards, which may fail to meet Canada’s requirements for safe use, and, while cost-effective to purchase, can be expensive to modify and maintain, and yield high scrap rates in production. Typical imported systems cost between $70,000 and $85,000 depending on the upgrades and rework required to bring them to Canadian standards. These systems, though advertised at much higher speeds, cap out at around 75 parts per minute, can have large downtimes and scrap rates between 15 and 30 per cent.

Starting at $300,000 with full safety certification, The Canadian Shield mask automation system produces double the number of masks per day with one operator. Inline vision and part rejection ensures that only quality masks leave the machine, minimizing labour costs and maximizing customer satisfaction. The new systems, which offer 90-plus parts per minute, less than four per cent scrap, and 91 per cent OEE, are now available to order.

The vision system is also sold separately as a modular addition for inline mask inspection and rejection. Starting at $30,000, this system ensures that only quality masks leave the machine and reduces labour costs for quality control.

Advertisement

- ABB calls for transition to high-efficiency technology to combat climate change

- Specialty steel manufacturer receives $5M from feds to improve technology