Siemens and Bentley Systems release digital twin software PlantSight

November 2, 2018

By Manufacturing AUTOMATION

November 2, 2018 – Siemens and Bentley Systems have announced PlantSight, a solution that uses as-operated and up-to-date digital twins to synchronize physical reality and engineering data in order to create a holistic digital context for any operating plant.

Every real-world operating plant is characterized by cumulative evolution, both to its brownfield physical condition and to the varied types and formats of theoretically corresponding engineering data. Accordingly, as-operated digital twins must reliably synchronize reflections of both the physical reality and its virtual engineering representations, comprehensively and accurately.

PlantSight coalesces project digital twins, and control systems digital twins, and will soon extend to performance digital twins, and component product digital twins.

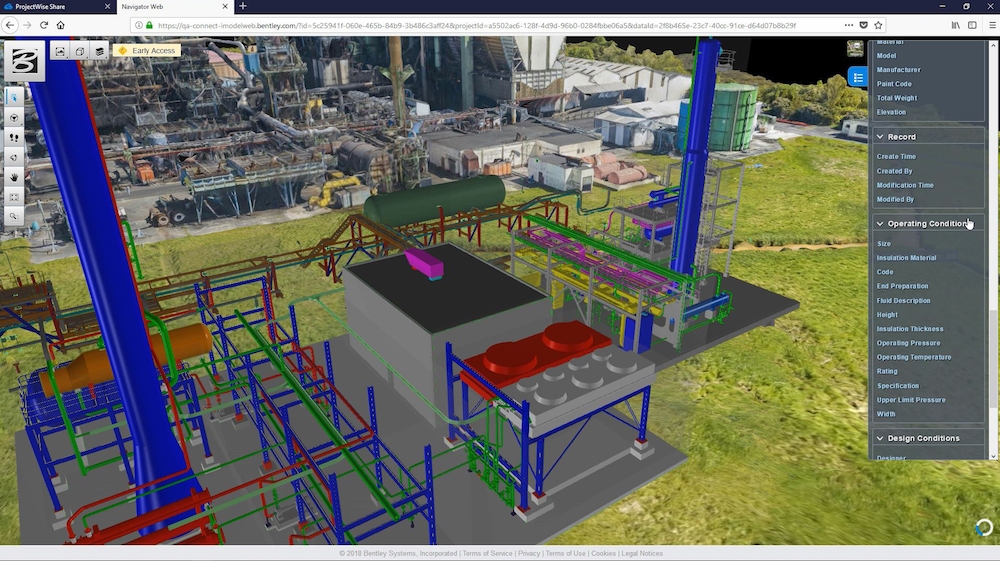

PlantSight mirrors the physical plant through “continuous” surveys and reality modelling cloud services. Overlapping photographs and (as needed) supplemental laser scans, from UAVs and ground-level imagery, are processed to generate spatially classified and engineering-ready reality meshes – the plant’s digital context, within which each tagged component can be geospatially located.

To synchronize with the plant’s evolving engineering data, PlantSight uses the Connected Data Environment (CDE). It includes information bridges from engineering models and an integration hub to accomplish the required semantic alignment for digital components (including their tag designations). PlantSight’s CDE is also populated by pertinent data from other sources, such as project deliverables and control systems inputs, to the degree referenced through digital component tags.

For engineers in operating plants, the value of an as-operated digital twin is determined by the accessibility and integrity of information that can be presented, and edited, in trusted formats of schematics and 3D models. PlantSight, through its new cloud service and web interface, fully integrates functional and spatial modeling. For the first time, engineers on site can have both accessible existing data, and accessible tool interfaces, to assure that as-operated changes are timely and accurately captured and managed through PlantSight’s ledger of changes.

The as-operated digital twin, through the cloud accessibility and securely open architecture of its CDE, provides immersive visibility throughout the operating plant lifecycle, including mixed-reality visualization of all information, and even more importantly, digital visibility for machine learning and analytics.

PlantSight digital twin cloud services will be marketed separately by both Siemens and Bentley, and early adopters are now being selected. The companies are now working to add to PlantSight state-of-the-art asset performance modeling (APM) capabilities, to make the most of services based on Siemens’ MindSphere IoT operating system. For manufactured digital components, Siemens’ Teamcenter PLM will provide immersive access to product digital twins for simulation and remediation.

Advertisement

- Global Automakers of Canada applauds Canada’s CPTPP legislation

- Centre stage: Matt Rendall, OTTO Motors