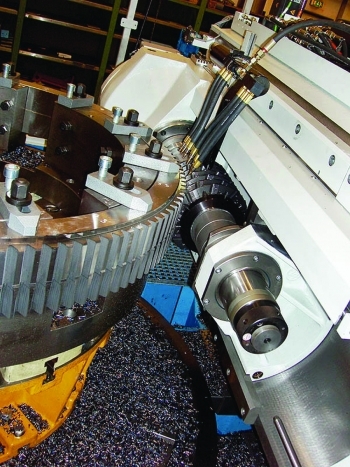

MAG has introduced integrated gear cutting capability on a VTC 2500H (vertical turning centre) for workpieces up to 2,700 mm in diameter. The new multi-axis machine combines gear hobbing and milling capabilities with the VTC’s wide range of turning, milling, drilling, threading and contouring capabilities. It can turn blanks and subsequently cut gear teeth, all in one setup. The machine’s ability to execute rough turning of the outside diameter and gear cutting on the inside diameter in one setup results in higher quality gears, the company says. It also eliminates a separate gear-cutting machine and reduces labour, part transfers, setups, work-in-process and plant footprint/overhead. This system is ideal for the part-making requirements of the wind and power generation industries, mining equipment, marine and other heavy machinery, the company says. The hobbing module is fully integrated into the VTC to allow turning, milling and hobbing or form milling of internal and external geared slewing rings. Two different heads are available with 36 or 46 kW power. They can hob modules up to 24 mm or form mill teeth up to 28 mm on parts with a maximum face width of 600 mm. The functionality of the gear manufacturing software is fully integrated into the turning centre’s control with one common HMI.

www.mag-ias.com

Advertisement

- Portable weld performance monitoring

- Video: Harting North America’s Han-Modular connectors and ECO line of housings