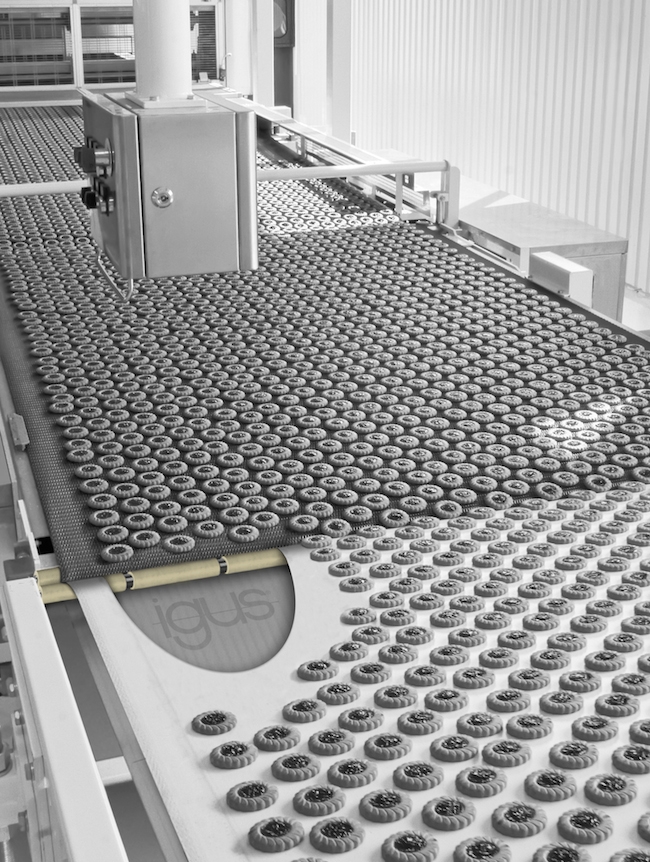

igus knife edge rollers for high-speed movement on conveyor belts

October 13, 2017

By Manufacturing AUTOMATION

Oct. 13, 2017 – igus says it has developed knife edge rollers made from plastic iglide H1 specifically for material handling and packaging applications that require higher transport speeds.

With this development, igus has expanded its range of knife edge rollers to a total of four material options. The new rollers are characterized by a better performance at higher conveying speeds and a longer service life at higher temperatures, says the company. Chemically resistant iglide H1 is the best choice in the knife edge roller range when the rollers are exposed to aggressive cleaning methods, says igus, noting that the rollers are particularly suitable in packaging, material handling, automation and food technology. Besides the new iglide H1 made for high transportation speeds, there is the universally used iglide P210. There are also the FDA-compliant materials iglide A180 for temperatures up to 194 degrees F and iglide A350 for temperatures up to 356 degrees F.

Advertisement

- Phoenix Contact TERMITRAB range boasts space-saving surge protection

- Revving up business: Opportunity awaits for Canadian automotive suppliers looking to expand