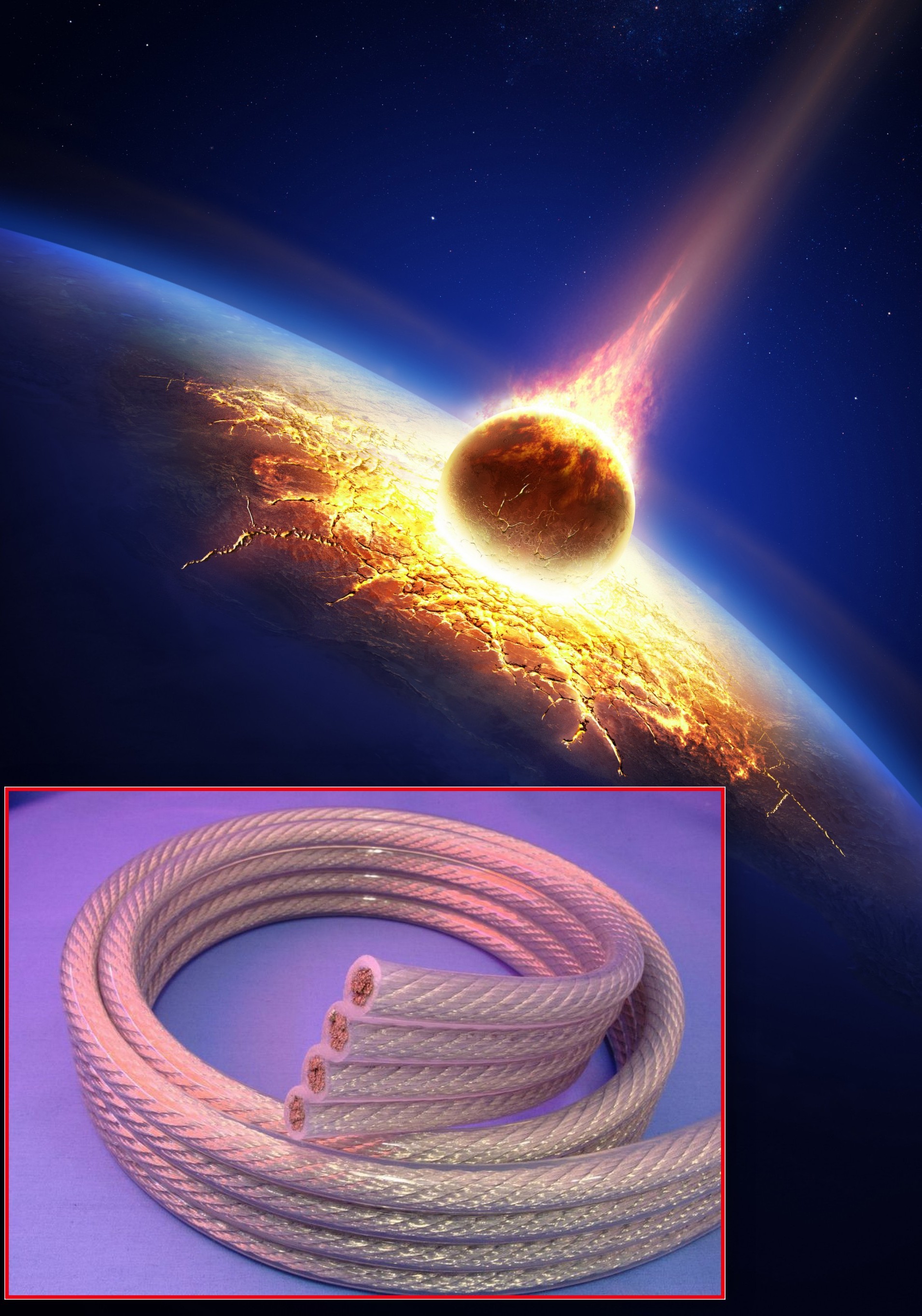

Sept. 15, 2014 – Cicoil’s highly flexible cables have been designed for use in applications exposed to harsh vibration caused by propelling force, automated machinery, excessive turbulence, intense wind, driving rain and rough seas, the company says. Cicoil uses a unique process of completely surrounding and encapsulating conductors in its shock-absorbing Flexx-Sil rubber jacket that renders them unaffected by constant shaking, sudden impact, severe vibration, G-Forces, extreme temperatures (-65 to 260 degrees C), salt corrosion, submersion in water, humidity, chemicals, ozone, radiation, UV light and the rigors of supersonic flight. As a result, the Cicoil cable does not require a clamping system (which is typically utilized with PVC, Polyurethane and Teflon jacketed cables) because the conductors cannot creep out of the Flexx-Sil jacket encasing them. The tear-resistant Flexx-Sil Jacket does not require conduit for protection, is self-healing from small punctures and outer cable jacket damage, and can easily be repaired in the field, according to the company. In addition, the cable will not wear, crack or deform when exposed tight bending, continuous flexing and operational stress.