Saving time: Scholle IPN Canada optimizes its production workflow

January 24, 2020

By Ruben Bastien

The packaging manufacturer cuts robot panel design lead time by 50 per cent with installation of automation software

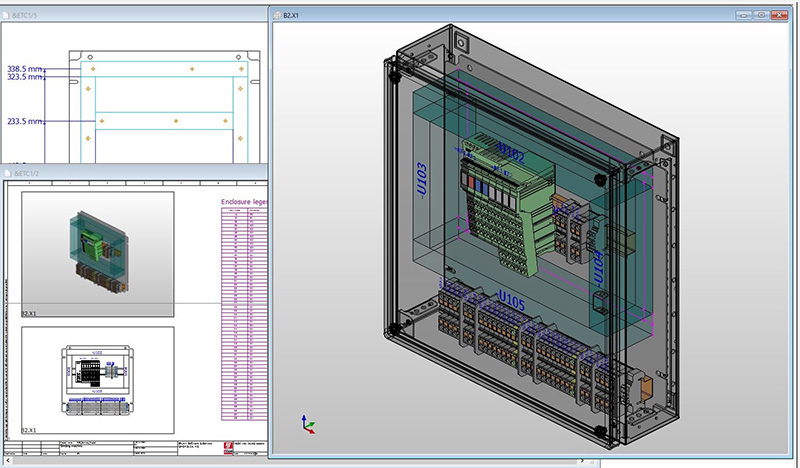

Scholle IPN Canada installed EPLAN's automation software. Photo: EPLAN

Scholle IPN Canada installed EPLAN's automation software. Photo: EPLAN Innovation comes in all shapes and sizes.

One company positioned to validate this piece of wisdom is Scholle IPN Canada, a packaging company that provides bag-in-box solutions that themselves come in all shapes and sizes.

Since 1947, the company has made breakthroughs in the industry that help brands add convenience to customers looking for packaged food and beverages, such as dairy products and electrolyte products.

The company specializes in aseptic packaging, a manufacturing process in which packages and containers are sterilized separately from their content.

Modifying robots

About a year ago, Scholle IPN Canada realized they needed to optimize their workflow on the production floor. The company started their transition using the EPLAN software for assistance in engineering the electrical panels for their production robots.

Electrical designers often need to reconfigure machines on the production floors, and require enough versatility to be able to do so efficiently.

From juice pouches to dairy bags, Scholle IPN Canada can pack various types of goods through any of the machines at its location in Montreal, Quebec.

But because of the legacy processes that have always been in place to properly retrofit the machines for new tasks, the company would constantly hit a productivity wall.

“We used to rely on old technology and everything needed to be converted from manual drawings into a CAD software,” explains Jean Philippe Linteau, engineer at Scholle IPN Canada.

“However, as the machines have become more complex, the tasks are becoming more complex as well. The modifications required by the machines are now too important for us to rely on how we used to do things.”

Saving time with automation

Since implementing EPLAN, Scholle IPN’s panel design and production time have drastically improved. According to Linteau, the company moved away from the process of drafting their designs on paper before redrawing everything on a computer software.

“Now, it’s all directly done through EPLAN,” he says. “We’re talking numbering, cross references, billing of material, etc. Even the fact that electrical symbols are integrated within the EPLAN helps making things easier for the company.”

Linteau claims they have reduced the time spent on drawings by 50 per cent. It used to take the team one month to draw schematics and now, it’s down to approximately two weeks.

They have also done away with the risk of mistakes when transposing everything from paper to software.

Updated specifications

Linteau says the company is better able to complete its ordering processes with the EPLAN Data Portal accessible within the software.

Manufacturers update their parts information and data sets directly to the EPLAN Data Portal repository, which ensures the information is always accurate.

The portal helps companies like Scholle IPN Canada find the exact parts with the right specifications within a few clicks of their design projects.

Competitiveness was a huge motivator in the decision to make the switch to the software. “This has allowed us to evolve at a very low cost,” says Linteau.

As robotics and automation started playing a more important role in their operations, he says the company needed to stay ahead of the curve by investing and making moves that would allow it to run as efficiently as possible.

In the future, Linteau’s plan is to expand the company’s usage of EPLAN, by adding features such as support for pneumatics, which he says would be a welcome addition.

Ruben Bastien is field marketing manager for EPLAN Canada.

Advertisement

- Endress+Hauser releases vibronic point level detector with mobile capability

- Mega Bloks to lay off 580 workers and close Montreal factory