Siemens develops physical distancing solution for manufacturers

June 5, 2020

By Manufacturing AUTOMATION

Photo: Siemens

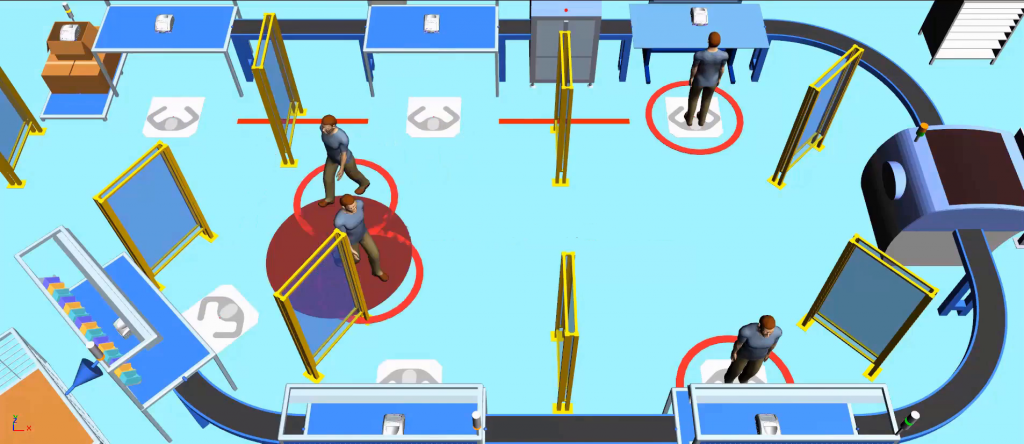

Photo: Siemens In response to coronavirus-related physical distancing measures in the manufacturing environment, Siemens has created a new solution that enables companies to quickly model how employees interact with each other, the production line and plant design.

The hardware-software solution also allows companies to build an end-to-end digital twin in order to simulate worker safety, optimize workspace layouts and validate safety and efficiency measures to help future-proof production lines.

Using Siemens’ SIMATIC Real Time Locating Systems (RTLS), companies can continuously measure distances between workers, provide real-time visual feedback to employees regarding their spacing from others and create a log of all movements and interactions over time.

“The combination of real time distancing management and digital simulations will help companies maintain safe work environments today and make educated decisions about ongoing and long-term optimization,” says Tony Hemmelgarn, president and CEO of Siemens Digital Industries Software, in a statement.

How it works

In order to implement this solution, Siemens’ SIMATIC RTLS transponders are embedded in badges worn as personal protective equipment by all employees.

RTLS receivers placed throughout the operation can then continuously track and record workforce movement. When two employees are in a risk scenario (e.g., less than six feet apart), their badges will display a warning, alerting them to the situation.

The data collected over time can be analyzed to identify “hot spots” where risk scenarios occur frequently.

Such situations become actionable via the digital twin, which is provided by the company’s Tecnomatix Process Simulate and Plant Simulation software. Using the collected data, new manufacturing layouts or workflows can be simulated until one is determined to provide the desired outcomes, which can then be implemented in the physical operation.

Manufacturers can also add traceability to the solution through Siemens’ on-premise solutions or an application such as the Trusted Traceability Application on MindSphere, the company’s cloud-based, open IoT operating system.

The traceability app enables rapid, comprehensive contact analysis in the event of an actual workplace illness. All movement and contact with the affected employee can be visualized, enabling rapid notification of those who came into close contact and selective (rather than site-wide) deep cleaning of exposed physical environments.

Advertisement

- Skills Ontario to host online skills competition for high school students

- Valiant TMS opens up HQ to non-profit that introduces women to skilled trades