Technology adoption has to start at the top

September 9, 2020

By

Paul Hogendoorn

Manufacturing CEOs are usually well intended when adopting Industry 4.0 technologies, but they are not comfortable with the whole technology conversation

Photo: vm/Getty Images

Photo: vm/Getty Images It’s been an interesting summer, to say the least. The challenges, solutions and new outcomes brought about by the sudden change in our world are wide ranging, and what “normal” is in the future will be different than what normal was in the past.

There is one “non-change,” or slow change, that continues to surprise me, and that is slow rate of adoption of digital technology on the plant floor.

My assumption was “social distancing,” working from home and the focus on the elimination of unnecessary contact points (i.e., paperwork) would have accelerated the adoption of technologies that have found their place into the rest of our lives – our homes, schools, banks and institutions, and much of our recreational and social activities, too – but that hasn’t happened. Not yet, anyway.

Prior to COVID-19, most small and medium manufacturers were contemplating what Industry 4.0 could mean to their company or industry, but few were taking concrete first steps. It was still an investigation for many, and although it was believed to be important, it didn’t seem to be urgent.

Then came COVID, and the ability to work from home and monitor machines, production and processes remotely became increasingly advantageous, stimulating a lot of additional urgent discussions, but still little actual “first-step” action from many. There are certainly exceptions to this, but by and large, the adoption of Industry 4.0 technologies by small and medium manufacturers is still surprisingly slow.

The reason for this, in my opinion, is the vision gap between the CEO and the people that any information technology related objectives get delegated to. Most manufacturing company leaders graduated through the ranks of production, or engineering, or perhaps even accounting.

Over the course of their careers, they have developed a familiarity and understanding with all of those facets of the operation. The folks immediately below them on the organizational chart share the same basic understanding of those primary elements of the business, although they may specialize in one particular area or another.

By and large, the adoption of Industry 4.0 technologies by small and medium manufacturers is still surprisingly slow.

“IT,” however, is often considered a “service” to the business, and the people deeply involved in information technology, or considering advanced technologies, are usually far more technology focused than they are day-to-day manufacturing focused. Whenever a conversation about new technology comes about, it quickly gets delegated to IT, because in the eyes of the executive management team, they are the most technically knowledgeable people.

The problem is, most of these technically smart people are several levels away from the CEO, and none of their responsibilities and objectives tie directly to the company’s vision or its overall performance.

The CEO, and the people that report directly to the CEO, don’t have an instinctive understanding and familiarity with technology, and the people who the technology objectives have been delegated to don’t speak the same language as the executive does, nor are they accountable for the same objectives.

The finance, engineering, administration and production departments are all accountable for a common set of interdependent goals, but the IT and advanced technology groups typically have their own specific goals completely apart from the other departments.

Many companies are slow to adopt – the exceptions are the ones where the CEO has a strong personal inclination towards technology.

Earlier this year, I was asked by the Excellence in Manufacturing Consortium (EMC) to weigh in on the topic of technology adoption by small- and medium-size manufacturing companies. After a lot of research and contemplation, my conclusion was that the CEOs are usually well intended in regards to adopting Industry 4.0 technologies, but they are not comfortable with the whole technology conversation, so they delegate it to someone they think is.

If a CEO delegated a financial objective to the CFO, the CEO would still have some basic financial aptitude to be able to stay up to date with the CFO, and keep the CFO’s efforts connected with the company’s vision and obligations to its stakeholders. The same is true if it was a production objective, an engineering objective, a new product objective, or even an administrative or a sales objective.

With advanced technology or Industry 4.0 objectives, the problem is often that the CEO believes they have to delegate the project to someone he or she is unable to communicate with, and that person is not part of the executive team that shares all the interrelated responsibilities to the company’s stakeholders (i.e., its customers, suppliers, staff and investors).

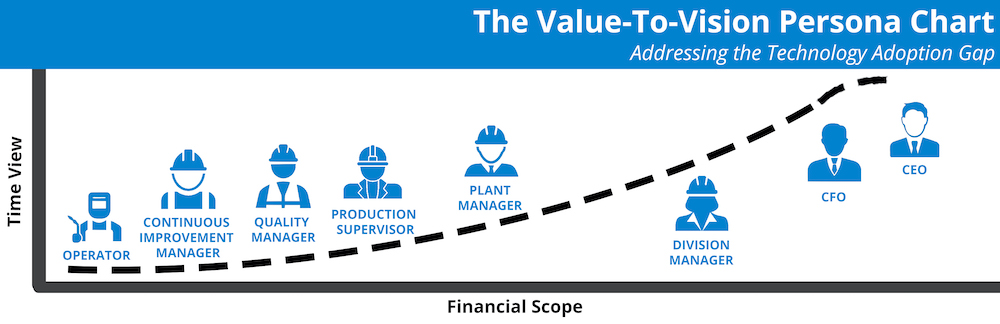

The value-to-vision persona chart, as described below, demonstrates the technology adoption gap. Photo: FreePoint Technologies

As part of that research, FreePoint developed a “value-to-vision persona chart” (pictured above). Roles on the left are very tactile, and in the present. On the far right, the C-suite scope of view is far longer term, and the metrics are financially, and sustainability, focused.

In the middle, you have department and plant management roles. The two positions missing on the value-to-vision connecting line are the IT manager and CTO. Although very important positions, they are often not directly in the line connecting the value-adding activities on plant floor with the vision – and accountability – to the stakeholders.

This, in my opinion, is why many manufacturing companies remain slow to adopt new technologies. There are exceptions, but in most of those cases, the exceptions are the ones where the CEO has a strong personal interest and inclination towards technology.

There are several ways to close this gap. One way is to make sure IT is not considered a “service” to be run as an independent, standalone department, or that “advanced manufacturing” is considered a research or development project. They need to be connected to the company’s vision directly, and to the accountability to the stakeholders.

Another way is to be aware of potential candidates within your organization that have a good sense for your company’s business and a strong personal inclination towards technology, and then encourage and support them to develop and advance their technology skills. And another is to investigate programs such as the CME’s Technology Assessment Program (TAP) to help you get started.

Technology adoption needs to start at the top. It can be delegated to a champion, but to make sure the right goals get accomplished for the company, the CEO needs to stay involved. Effective delegation requires communication, goals, checks and balances. Anything less is abdication, not delegation.

_____

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people.

This article originally appeared in the September 2020 edition of Manufacturing AUTOMATION.

Advertisement

- ATS Automation announces closures, layoffs in transportation segment

- International Manufacturing Technology Show begins online Sept. 14