Top mobile apps for manufacturing

October 5, 2018

By Treena Hein

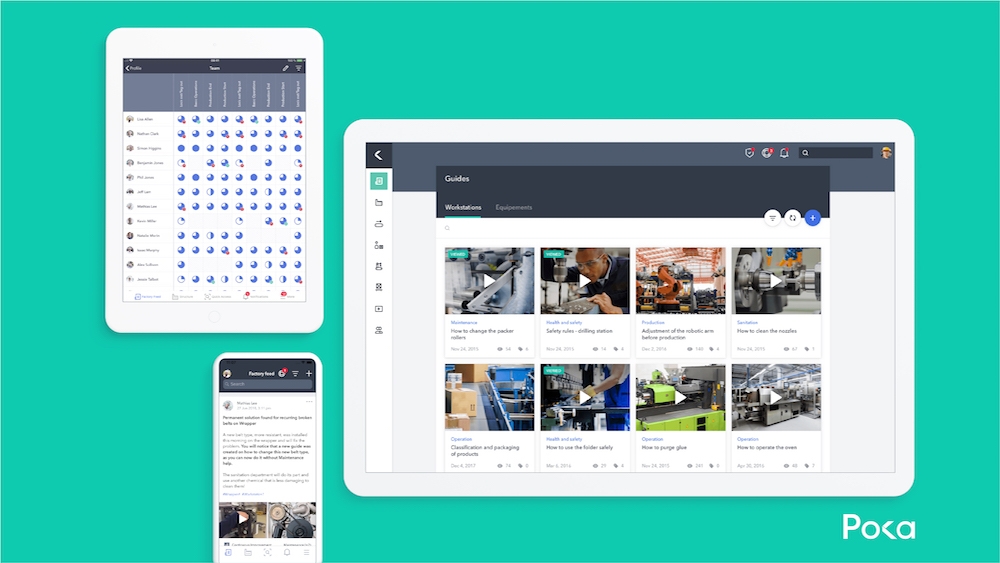

Quebec-based app maker Poka creates customized communication and training solutions for manufacturers

Quebec-based app maker Poka creates customized communication and training solutions for manufacturers October 5, 2018 – We’ve compiled a partial list of some of the major apps in the manufacturing world. Companies not listed are welcome to alert us to your app.

Siemens

The Siemens Digital Innovation Platform integrates apps and software for product lifecycle management, application lifecycle management, electronic design automation, manufacturing operations management and more. It supports open IoT, 3D modeling and manufacturing operations.

Rockwell Automation

One app example from Rockwell is TeamONE, which both syncs and keeps industrial communications local, being designed for hybrid connected industrial environments. It incorporates worker knowledge with data from automation devices.

Schneider Electric

Various apps and software solutions provide a collaborative, standards-based foundation that unifies people, processes and assets for continuous operational improvement and real-time decision support.

Honeywell

Various apps and software provide a real-time view of all materials, parts and finished goods flowing through manufacturing operations to optimize processes, ensure product pedigree and maintain consistent quality control.

Emerson Electric

Many apps related to IIoT and more.

ABB

Various apps within the firm’s manufacturing execution system provide the seamless orchestration and synchronization of all the entities involved in the manufacturing process, giving insight to operators, production engineers, plant managers and more.

Yokogawa

Among other apps, Yokogawa’s Field Assistant enables digital transformation of activities in and outside a plant, such as equipment care and predictive maintenance. It helps to enhance safety, reliability, efficiency and seamless communication, for work inside departments and across organizations.

Microsoft

The Microsoft Azure IoT suite of apps includes Remote Monitoring, Connected Factory, Predictive Maintenance and Device Simulation.

Oracle

Oracle Manufacturing Cloud provides apps to manage processes and streamline the production cycle as part of an entire supply chain system. The firm’s asset maintenance software and apps provide a complete view of all types of assets, managing maintenance to extend asset life.

iFIX (by GE Mobile)

This app helps deliver faster insight and operational efficiency in asset management. The firm states that the goal is designed to always provide the operator with the most relevant information, in context. The overall interface layout is designed to provide operators with the most informed view of the problem or task at hand, personalized to them.

Humanity

This app enables managers to spend less time scheduling (up to 80 per cent less) and managing manufacturing staff. It includes the capacity to import and integrate business data to forecast and predict scheduling needs, to collaborate and communicate with coworkers, to create training programs to onboard new staff and facilitate staff development, and more.

Salesforce for Manufacturing

This firm’s apps and app platforms can “make each interaction for inquire-to-order and field service operations a personalized experience, enable 24/7 customer-centered collaboration across the ecosystem, and unleash the next wave of service innovation powered by connected product data.”

SAP

In its apps that digitize manufacturing (HR, blockchain, materials management and more), SAP says it can optimize assets by supporting manufacturing and production priorities “with customer centricity, ‘segment of one’ service, digital smart products, digital supply chain and smart factories, and new business models and services.”

Poka (pictured above)

Poka apps (for operations, health and safety, quality assurance, HR and more) allow access to real-time information to solve recurring problems, more easily train staff, digitize lockout tag-out procedures, standardize processes, assign maintenance tasks, follow-up and more. They also enable collaboration across departments, shifts and facilities, sharing of best practices of the most-skilled workers (limiting the future loss of knowledge) and measurement of employee performance through key indicators.

NetSuite Manufacturing Edition

NetSuite Manufacturing Edition is a cloud-based integrated manufacturing app that tracks inventory and warehouse activities and links them to the value chain. It provides manufacturers ways to manage inventory level stocking at multiple locations. In addition, the app helps warehouse managers manage bills of materials, barcoding procedures, shipping processes and more.

SYSPRO

This system integrates, synchronizes and controls the manufacturing lifecycle, keeping finished inventory at a minimum, simplifying forecasting, planning for materials requirement and capacity, and more. There is an advanced scheduling functionality and the ability to track actual labour versus estimated labour.

LeanApp and LeanMan

The LeanApp is described as “the Kaizen Event app for iPad,” designed to help Lean practitioners measure and analyze processes. Users enter measurement data within their Rapid Process Improvement Workshops; the app then interprets this data and generates reports that can be shared instantly. Similarly, LeanMan allows manufacturing businesses to observe and measure their production process data in real time, and receive interpretation and reports instantly to help identify where process improvements can be made.

Read about how these apps are being used in manufacturing operations here.

Treena Hein is an award-winning Ontario-based freelance science and tech writer.

This article originally appeared in the October 2018 issue of Manufacturing AUTOMATION.

Advertisement

- Study: Canadian firms are overconfident when it comes to cyberattacks

- ENI58L rotary encoder with BlueBeam from Pepperl+Fuchs reaches high rotation speeds