U of Waterloo, NRC partner on reducing 3D printing costs for manufacturers

January 6, 2021

By Manufacturing AUTOMATION

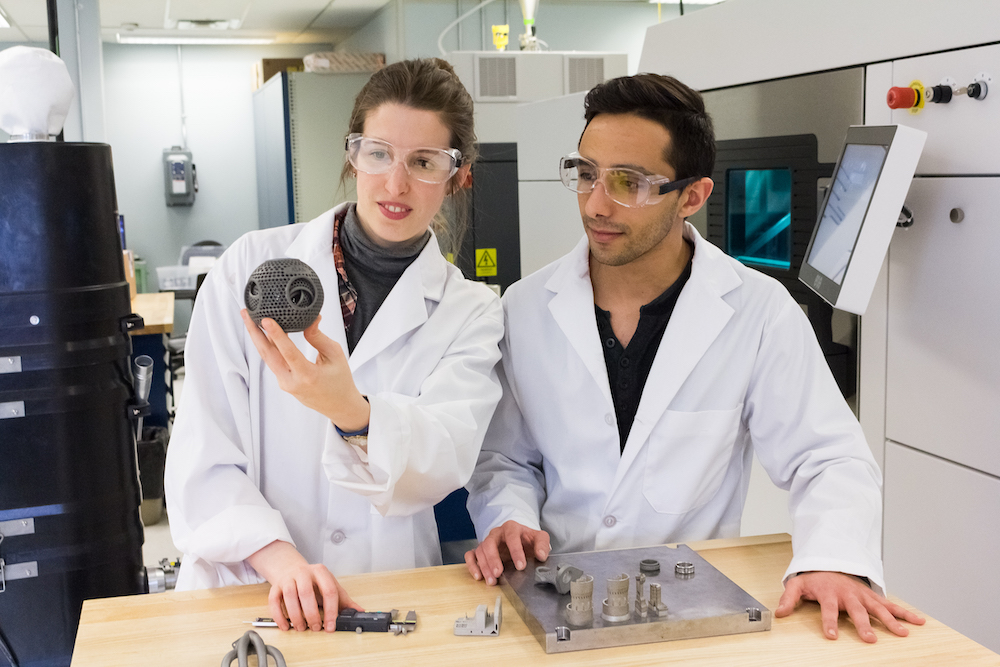

The University of Waterloo and the National Research Council of Canada will develop new powders and research how to lower materials costs for metal 3D printing. Photo: University of Waterloo

The University of Waterloo and the National Research Council of Canada will develop new powders and research how to lower materials costs for metal 3D printing. Photo: University of Waterloo The University of Waterloo and the National Research Council of Canada (NRC) are partnering to help Canadian companies use metal 3D printing technologies.

The collaboration between the NRC and the Multi-Scale Additive Manufacturing (MSAM) Lab at Waterloo will run for at least seven years.

“We want to create in southwestern Ontario a unique ecosystem to support metal additive manufacturing (AM) in terms of research and development and to translate competencies to industry partners,” says Mihaela Vlasea, the associate director of MSAM.

The partnership combines MSAM’s expertise in metal AM process optimization with the NRC’s experience in materials science and metal powders development to enable research from powder to part.

$2.6M in new equipment

Teams at Waterloo and the NRC have worked closely for the past three years in the areas of metal AM and process optimization, materials and product characterization, standardized testing and validation.

The collaboration will build on that relationship at a new NRC facility in Mississauga, Ont. that was officially inaugurated on Nov. 16.

The site will launch powder synthesis, recycling and characterization capabilities in Ontario to customize AM and reduce material costs for industry applications.

To support this collaboration, the NRC provided nearly $2.6 million worth of equipment to Waterloo as part of its Advanced Manufacturing Supercluster Support program, led by the NRC’s Automotive and Surface Transportation Research Centre.

The equipment will be housed at the new Mississauga facility and the university. As part of this collaboration, both partners will also support student research.

New powder development

A major thrust of the project will be the development of new AM powders – the raw materials at the heart of the technology – using metal alloys that currently aren’t available or are prohibitively expensive.

Researchers will also study re-using and recycling leftover powders, and the use of cheaper, less-refined powders that may still be capable of producing high-quality parts.

The underlying objective is to make AM technology economically viable for more Canadian manufacturers, either by creating new commercial powders – which now number less than two dozen – or dramatically reducing the costs of using existing powders.

The research teams will also study the production of powders by the Canadian mining industry of sufficient quality for AM processes.

“I think we can open up new market sectors by empowering people who currently don’t even think about additive manufacturing because their materials don’t exist or they just cost too much,” says Vlasea, a professor of mechanical and mechatronics engineering at Waterloo.

Metal AM, also known as 3D printing, is now largely limited to high-end, low-volume parts in the aerospace and biomedical fields. The goal is to extend use of the technology to industries including automotive, nuclear and oil and gas.

Advertisement

- Report: Canadian manufacturing business conditions improved in December

- Quebec manufacturing sector warns against new COVID-19 lockdowns