Virtual Event

Future of Automation 2021

September 29, 2021 at

1:00pm ET

Pleora simplifies artificial intelligence (AI) for end-to-end quality inspection of manufactured parts, consumer goods, food & beverage, and print & packaging.

- Reduce errors that result in poor product quality, waste, and costly secondary screening

- Maintain brand standards and meet safety and compliance requirements

- Inspect challenging materials (metal, glass, fabric, wood, and irregular shapes)

- Automate error-prone human inspection at key points in manufacturing processes

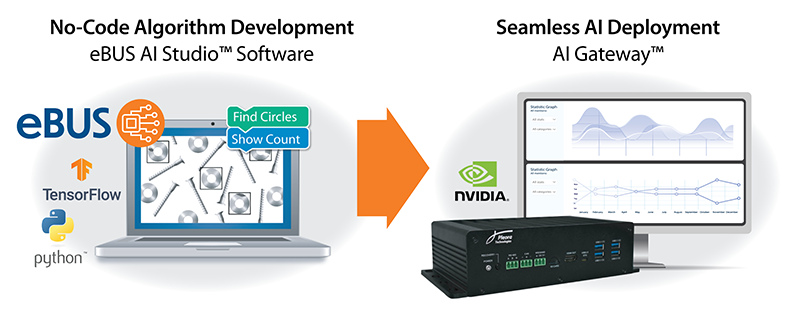

Pleora’s AI platform is a complete software and hardware solution to simplify deployment of advanced quality inspection. eBUS AI Studio is a drag-and-drop ‘no code’ algorithm development platform to develop AI inspection plug-ins. Non-experts can develop AI and traditional computer vision inspection plug-ins in hours instead of days. Advanced users can leverage eBUS AI Studio to rapidly prototype and test algorithms, mix computer vision and AI skills, customize open source models, and streamline production deployment.

In addition, off-the-shelf AI plug-ins are available for common inspection requirements and hyperspectral imaging. With these off-the-shelf plug-ins, end-users can quickly test, train, and deploy AI in their application without extended programming to help speed time-to-market.

Plug-ins are optimized for Pleora’s AI Gateway edge processing platform, which integrates seamlessly with existing inspection systems. With this ‘hybrid’ approach, manufacturers can evolve towards more advanced AI without disrupting proven computer vision inspection applications, existing infrastructure, and end-user processes.

Adding AI to Inline Inspection

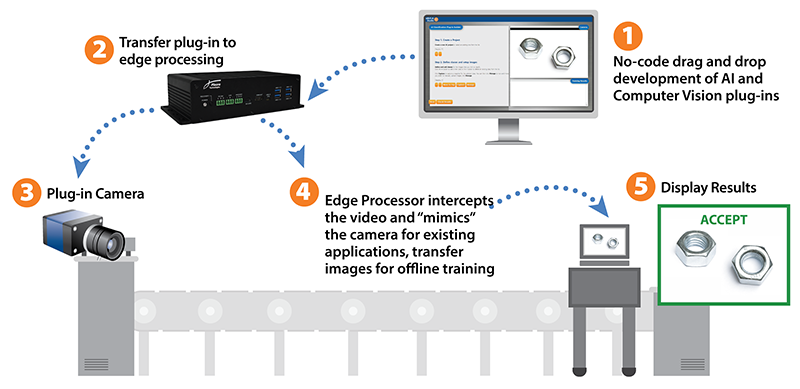

Adding AI to existing inline inspection applications helps increase profitability and lower risk by reducing secondary inspection, product waste, and recalls. Algorithms developed in eBUS AI Studio are seamlessly deployed on the AI Gateway. The AI Gateway transparently intercepts camera images, applies the AI inspection skills, and transfers data for processing and continuous offline algorithm training.

Automating Manual Inspection

Pleora’s AI inspection system automates offline manual tasks at different points in the manufacturing process, adds decision-support for human operators, and digitizes work instructions. The plug-and-play system is easily trained on a manufacturer’s unique data to implement end-to-end quality checks and workflows without requiring software coding skills. An intuitive user display guides operators through the manufacturing process and automatically identifies and visually highlights differences and deviations.

About Pleora

Global manufacturers rely on Pleora’s expertise in AI, real-time sensor connectivity, and rugged networking to shorten time-to-market, reduce risk, and lower costs. Established in 2000, the company serves over 1500 active customers in the industrial automation, medical imaging, and security and defense markets. Learn more at pleora.com and qualitycontrol.ai.