SAIT Polytechnic opens $1.4 million high-tech learning facility

September 4, 2012

By Manufacturing AUTOMATION

Calgary’s SAIT Polytechnic has opened its brand-new $1.4 million high-tech learning facility.

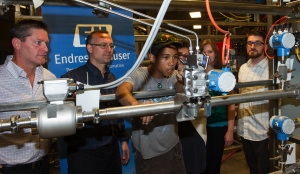

Endress+Hauser Canada, which played a major role in creating the new facility, presented the facility’s keys to SAIT faculty in Calgary on Aug. 28. The new 1,800 square foot Endress+Hauser Process Lab, located in the new Trades and Technology Complex, will educate approximately 600 students in its inaugural year and will feature more than $1.275 million in top-of-the-line equipment.

The first students from SAIT’s MacPhail School of Energy will experience the unique training facility starting this month. Most of the students will go on to embrace careers in instrumentation, chemical, mechanical and electrical engineering and, in particular, in the application of process automation.

“The demand for process automation and accurate measurement systems is growing at a rapid pace,” says Richard Lewandowski, president of Endress+Hauser Canada. “To meet these present and future needs, we and our industry must have access to quality personnel who have been well-trained and who can join the workforce with ready-to-use knowledge. I could not think of a better solution than the one we’ve developed over the course of the past two years with SAIT.”

The new lab in the Johnson-Cobbe Energy Centre is set up for 16 students per session who will have access to hands-on training with state-of-the-art equipment for process engineering. Endress+Hauser flow instruments are installed in a real life-like setting allowing students to gain experience with devices in their natural condition.

With several flow stations and multiple sets of repeated equipment, the closed process lab is designed with interactivity in mind to eliminate the need to wait for access to a device, ensuring that all students are engaged during a lecture. Endress+Hauser also provided the necessary process pumps, tanks, piping, fittings and installation to ensure the materials and resources used in the lab are commissioned and maintained in optimal operating condition. The curriculum will include Instrumentation Theory, Control Theory, Control Systems and Project Management.

“Anyone can build a classroom,” says Mary MacDonald, dean of the MacPhail School of Energy. “But building an effective learning environment, particularly in the fields of trades and technology, requires partnerships with companies that are innovative and very active in the field. Measurement and industrial automation is not something you can learn solely in textbooks, it requires exposure to multiple scenarios, complex procedures and changing conditions. It also requires modern tools that students will encounter in the field.”

Advertisement

- Robotic simulation software

- Economy grew by 1.8 per cent in Q2, on stronger business spending, StatsCan report says