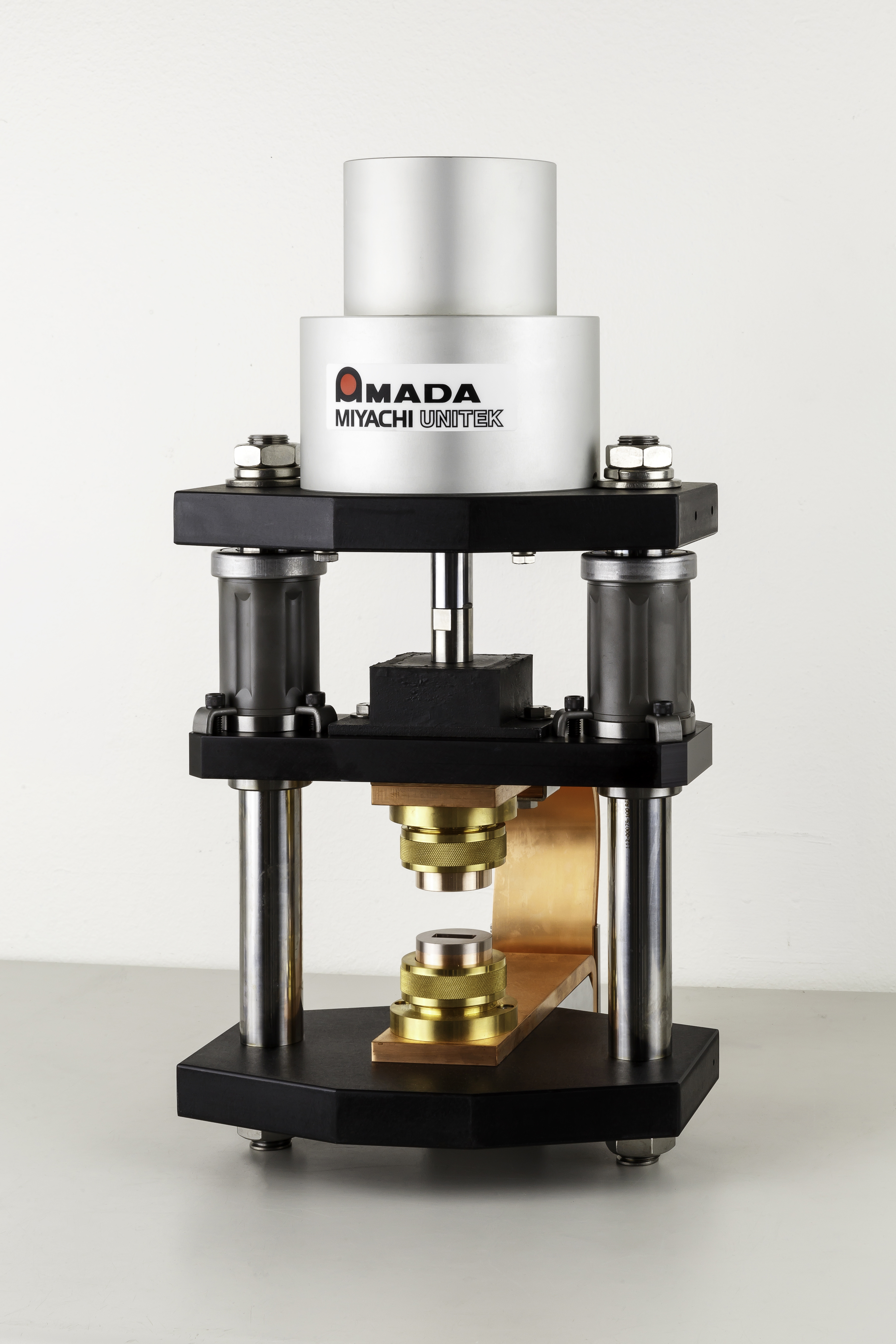

KN-II Series pneumatic weld head from Amada Miyachi America for opposed electrode welding

August 28, 2018

By Manufacturing AUTOMATION

August 28, 2018 – Amada Miyachi America, a manufacturer of resistance welding, laser welding, marking, cutting and micro-machining equipment and systems, is offering the KN-II Series pneumatic weld head for opposed electrode welding applications that require fast follow-up to prevent material expulsion.

The KN-II works for welding ring or annular projections with a perimeter length ranging from 0.40 to 7.0 inches, and for micro-electronic cap welding applications requiring co-planarity. The KN-II is used to weld sensors, frequency devices, filaments, heating elements, photonics packages, strain gauges, transducers and more.

With its fast force follow-up feature, the weld head eliminates weld expulsion, preventing entrapment of ejected materials in projection-welded electronic devices – a common cause of particle impact noise detection (PIND) failure.

The KN-II features a dual cylinder design that delivers more than 4,000 pounds of weld force. With a die-set design, the weld head boasts rigid construction using a 25 micron matched linear ball bearing bushing and tie rod for precise positioning and planarity. It can be configured for use with any manual or automated welding system and offers simple actuation using the Benchmark™ SS-1 pneumatic weld head controller.

This weld head is most frequently paired with Amada Miyachi Pulsar Series capacitive discharge power supplies or IS Series inverters. Optional features for the KN-II series include integrated glovebox systems, vacuum-backfill options and an integrated SS-1 weld head controller.

Advertisement

- U.S., Mexico reach trade ‘understanding’ to overhaul NAFTA: Trump

- David Doyle announced as new CEO of HEIDENHAIN