FANUC adds 5-axis simulation to CNC machine training software

June 11, 2020

By Manufacturing AUTOMATION

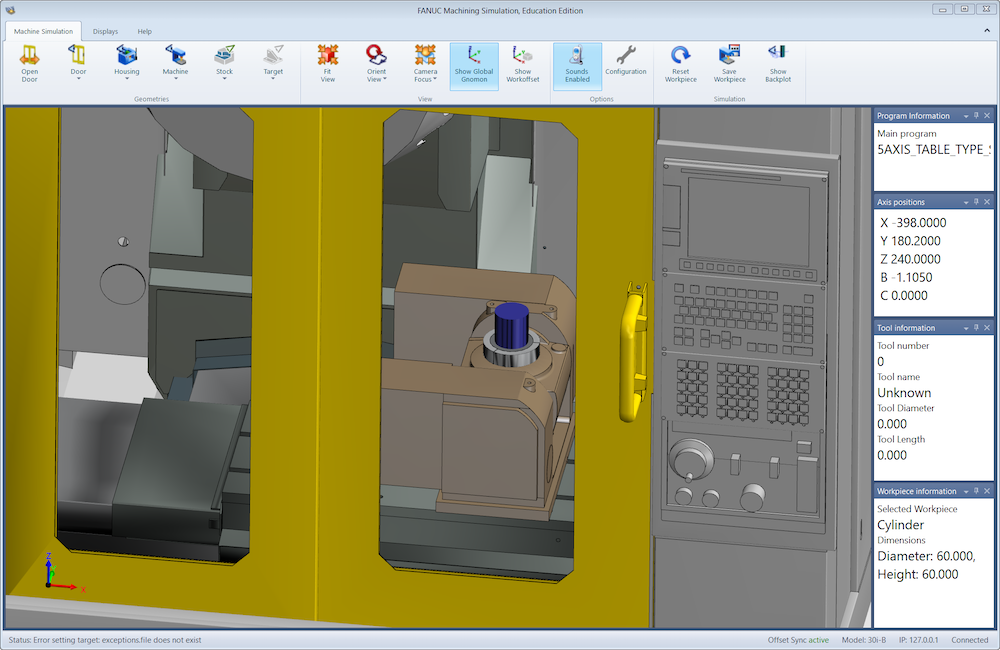

FANUC's table-type CNC machine simulation software. Photo: FANUC

FANUC's table-type CNC machine simulation software. Photo: FANUC FANUC America is expanding its CNC training offerings to include 5-axis simulation.

The company’s Machining Simulation for Workforce Development provides training for controls operation and part programming in a virtual environment.

With more operations looking to produce complex parts used in high-tech industries, the demand for 5-axis operators is growing – but the skills gap means there is a shortage of machine tool operators available.

FANUC’s training solution is for both new workers and existing workers looking to upskill.

The Complex Milling Extension option combines FANUC’s CNC Guide and simulation software that can now operate as one of the three main 5-axis mill kinematics.

The addition of 5-axis simulation offers an immersive environment to practice and understand advanced machining techniques.

Since 5-axis machining involves more complex machine setups, the simulation software teaches users how to take advantage of the unique options and features – and experiment with and prove out the machine setup and/or part program before modifying the actual machine.

The offering also includes training on a 3-axis mill and a 2-axis lathe for maximum configuration flexibility.

Via a digital twin, the 5-axis machining simulation allows users to learn how to setup and operate three common advanced 5-axis milling machines: mixed type, tool type and table type.

Advertisement

- JMP Solutions partners with Vexos on federal contract to produce 10K ventilators

- SICK debuts digital solutions portfolio for access to sensor data