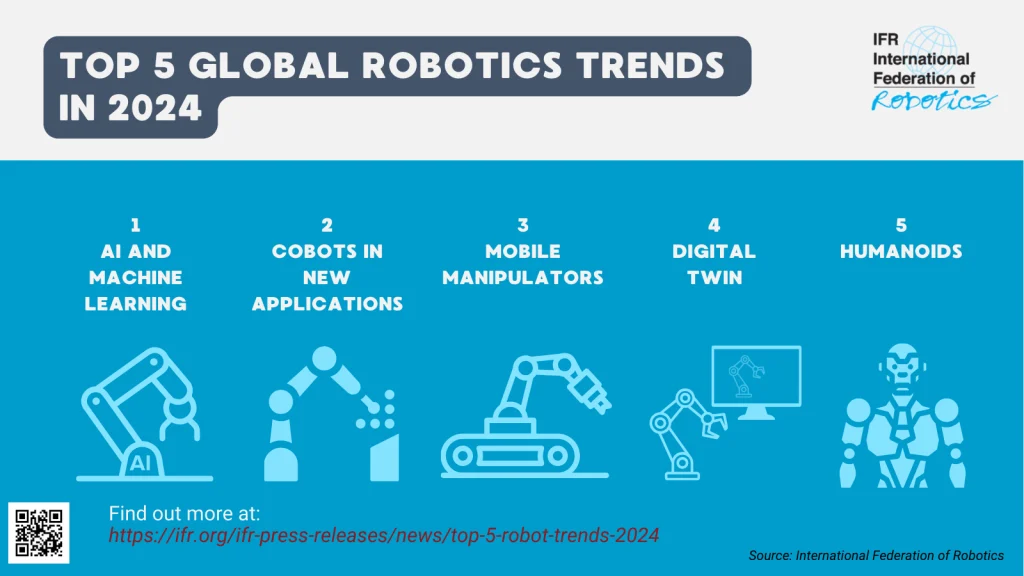

International Federation of Robotics shares top robotics trends for 2024

February 21, 2024

By Manufacturing AUTOMATION

Image: International Federation of Robotics

Image: International Federation of Robotics The International Federation of Robotics (IFR) has shared a press statement outlining the top global robotics trends for 2024. The stock of operational robots around the globe hit a new record of about 3.9 million units, shares the organization. This demand is driven by several technological innovations.

1 – Artificial Intelligence (AI) and machine learning

The trend of using AI in robotics and automation keeps growing, says IFR. The emergence of generative AI opens up new solutions. This subset of AI is specialized to create something new from things it’s learned via training and has been popularized by tools such as ChatGPT. Robot manufacturers are reportedly developing generative AI-driven interfaces which allow users to program robots more intuitively by using natural language instead of code. Workers will no longer need specialized programming skills to select and adjust the robot’s actions, shares IFR.

Another example, says IFR, is predictive AI analyzing robot performance data to identify the future state of equipment. Predictive maintenance can save manufacturers machine downtime costs. In the automotive parts industry, each hour of unplanned downtime is estimated to cost US$ 1.3 million – the Information Technology & Innovation Foundation reports. This indicates the massive cost-saving potential of predictive maintenance. Machine learning algorithms can also analyze data from multiple robots performing the same process for optimization. In general, the more data a machine learning algorithm is given, the better it performs.

2 – Cobots expanding to new applications

Human-robot collaboration continues to be a major trend in robotics. Rapid advances in sensors, vision technologies and smart grippers allow robots to respond in real-time to changes in their environment and thus work safely alongside human workers. IFR explains that collaborative robot applications offer a new tool for human workers, relieving and supporting them. They can assist with tasks that require heavy lifting, repetitive motions, or work in dangerous environments.

The range of collaborative applications offered by robot manufacturers continues to expand.

A recent market development, says IFR, is the increase of cobot welding applications, driven by a shortage of skilled welders. This demand shows that automation is not causing a labour shortage but rather offers a means to solve it. Collaborative robots will therefore complement – not replace – investments in traditional industrial robots which operate at much faster speeds and will therefore remain important for improving productivity in response to tight product margins.

New competitors are also entering the market with a specific focus on collaborative robots. Mobile manipulators, the combination of collaborative robot arms and mobile robots (AMRs), offer new use cases that could expand the demand for collaborative robots substantially.

3 – Mobile manipulators

Mobile manipulators – also called “MoMas” – are automating material handling tasks in industries such as automotive, logistics or aerospace. They combine the mobility of robotic platforms with the dexterity of manipulator arms. This reportedly enables them to navigate complex environments and manipulate objects, which is crucial for applications in manufacturing. Equipped with sensors and cameras, these robots perform inspections and carry out maintenance tasks on machinery and equipment. One of the significant advantages of mobile manipulators is their ability to collaborate and support human workers. Shortage of skilled labour and a lack of staff applying for factory jobs is likely to increase demand, predicts IFR.

4 – Digital twins

Digital twin technology is increasingly used as a tool to optimize the performance of a physical system by creating a virtual replica. Since robots are more and more digitally integrated in factories, digital twins can use their real-world operational data to run simulations and predict likely outcomes. Because the twin exists purely as a computer model, it can be stress-tested and modified with no safety implications while saving costs. All experimentation can be checked before the physical world itself is touched. Digital twins bridge the gap between digital and physical worlds.

5 – Humanoid robots

IFR notes that robotics is witnessing significant advancements in humanoids, designed to perform a wide range of tasks in various environments. The human-like design with two arms and two legs allows the robot to be used flexibly in work environments that were created for humans. It can therefore be easily integrated e.g. into existing warehouse processes and infrastructure.

Advertisement

- Matheus Bulho to lead software and control segment at Rockwell Automation

- AI revolutionizing industrial robotics in 2024: ABB robotics division president shares insights