Pilz Canada: We make Canada safer. A little bit every day. ™

Pilz Canada: We make Canada safer. A little bit every day. ™

Safe automation Made in Germany

Pilz is known all over the world as a global supplier of safe automation products, systems, and services.As well as offering complete automation of your plant and machinery, we also supply individual safety technology components. Out safety components are open, so they can easily be integrated into your existing automation environment. Benefit from our expertise in safe automation technology.

Pilz is the technology leader for safe automation

Technology leader in safe automationFor over 30 years we have been the technology leader in safe automation technology, supporting companies in the field of industrial automation. Numerous companies throughout the world place their trust in our safety expertise. That’s because our innovation and technical solutions for industrial automation speak for themselves. We have made it our goal to make the world safer.

Our mission is: We automate. Safely. And you, as the customer, are always at the centre.

Complete safety and automation supplier

It all began with control technology and the “Pilz E-STOP relay PNOZ”, the world’s most widely used safety relay. Today we offer numerous safety solutions for machine automation, worldwide in almost every sector. Over recent decades we have specialized on all issues relating to safe automation. Alongside products we also offer safety and automation services.Your future in safe automation

Whether it’s Industry 4.0, industrial security, or digitalization. With us as a partner, these are challenges that you will overcome in a way that’s future proof. Whether it’s a machine, a system, or a whole plant. We have solutions to meet your requirements.Benefit from safe automation

There are many benefits to automation, which today is used in many industries across the world. When you automate machines, or even entire manufacturing and production facilities, you not only simplify processes but also increase quality and productivity.

However, the safety aspect is very often neglected with industrial automation, and not just to the detriment of staff. Damage to materials and tools and the consequent downtimes are just some of the negative consequences. It’s worse still when people are injured. Also, if sate inspections establish that simple safety standards are not being met, then closure of the whole plant in inevitable. Quick and costly investments in safety measures will be needed to allow the plant to be put back into service.

With Pilz at your side as a partner, such cases can be avoided. We know which requirements are important for safe automation and are happy to support you with the implementation and solution. Because when it comes to complying with machinery safety requirements, many countries have regulations ranging from non-binding recommendations to mandatory laws.

We’re happy to support you with your individual challenge in safe automation.

For more information visit Safety in automation - Pilz CA

Pilz Seven steps to safe automation

Our checklist provides the right introduction to safe automation:

- Do you know the relevant standards in your industry?

- Which safety standards apply to your industry?

- Which laws for compliance with machinery safety requirements are mandatory in your country?

- Are you familiar with the Machinery Directive and how to apply it?

- Which laws must you consider when exporting machinery?

- Does your machine have a valid conformity assessment and CE mark?

- Are you using the right safety technology?

The desire for safety is a basic human need. Staff who feel safe are more efficient and more productive. So, it follows that safety has as a long-lasting effect on your company’s success. With the optimum use of safety technology, plant and machinery is also able to run smoothly, thereby increasing production quality.

An overview of the benefits of safe automation:

- Incase productivity – enjoy greater success with safe, efficient workflows.

- Reduce absenteeism – better health and safety for your staff.

- Minimize downtime – safety systems with integrated diagnostics enable rapid troubleshooting when something goes wrong.

Services covering the plant and machinery lifecycle

Pilz Automation Safety Canada as a global leader in machine safety supports your business with our services in the field of machinery safety and automation. Our extensive portfolio includes consulting, engineering, and Certified safety training. Our service specialists will ensure you get the maximum safety for your machine.

Regardless of where a machine is manufactured and where it is operated: We guarantee identical standards in automation and safety across the world.

We develop solutions even for the most complex safety issues for national and international industrial companies. With our international team of committed staff, we help you achieve the best possible manufacturing processes to optimise the availability and productivity of your plant across the world.

How our services can help you:

- Implementation of increased safety into new production plants through the identification of potential risk areas.

- Support on safe plant or machine retrofit projects to increase productivity and safety.

- Ensure compliance requirements by implementing safety technology into plant and machinery.

- Pilz expert support, simplifies introducing highly technical machines while setting up relevant safety measures.

- Trained Staff on machine safety, guarantees optimum automation and maximum plant availability and safety.

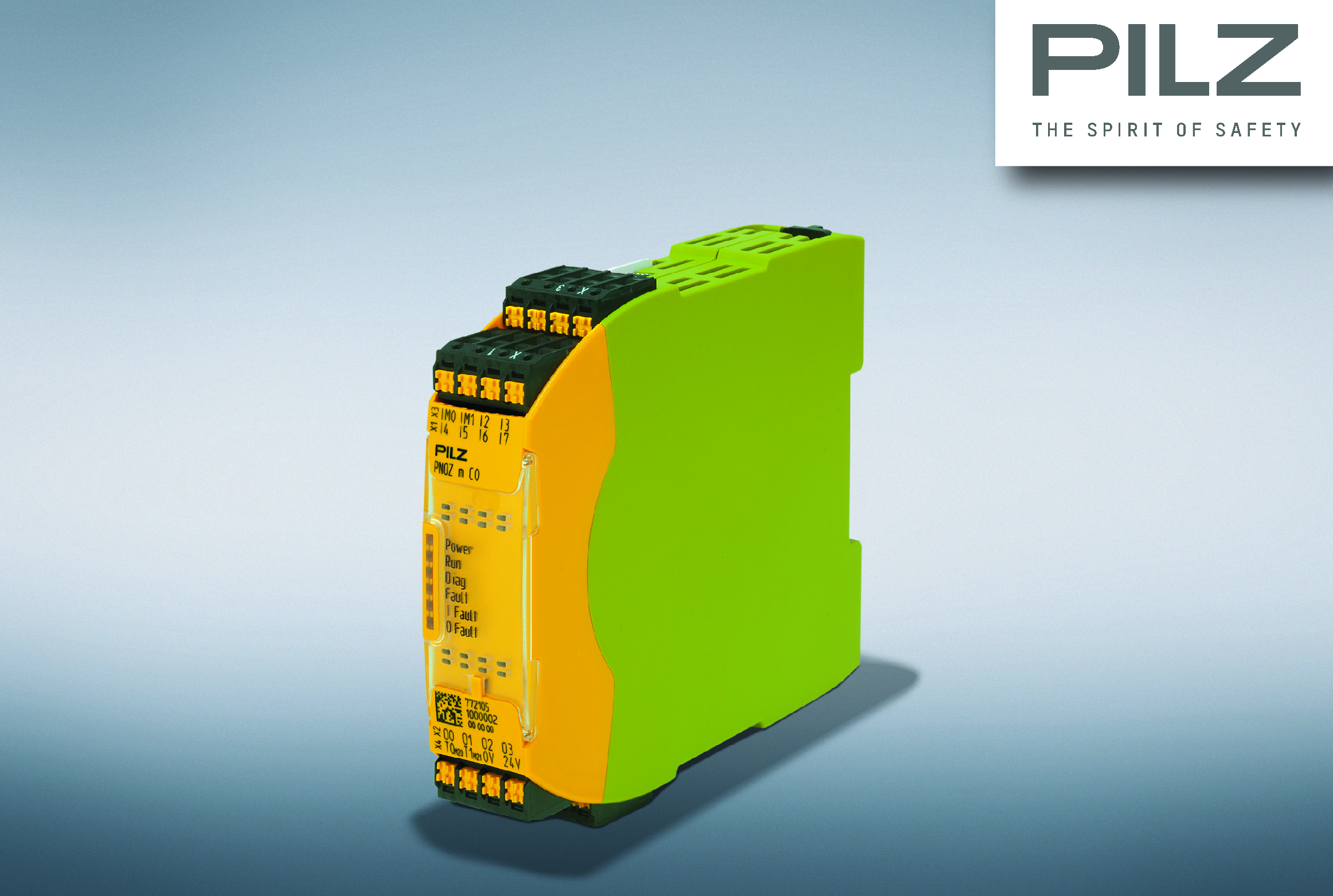

The smallest safety controller PNOZmulti 2 – PNOZ m C0

With the ever-evolving complexity of automation machinery the need for expanded flexibility in the control of the machine while keeping cost low is an industry need. Pilz Automation has been serving this need with its well established PNOZ Multi line of small safety controllers.

The latest addition to this product family is the smallest of these controllers the PNOZ m C0. Using the same free and easy to use configuration software PNOZ multi configurator the PNOZ m C0 saves cost while remaining highly flexible.

The 22.5mm wide housing will allow the controller to fit into the smallest control cabinet. The PNOZ m C0 has 8 safe inputs and 4 safe outputs allowing up to four safety functions in a wide range of safety applications up to PL e EN ISO 13849-1 or SIL CL 3 EN IEC 62061. This PNOZ m C0 can do the job of 4 safety relays in the space of one at a similar cost to 2 traditional relays.

This small relay could for example monitor an e-stop, a light curtain, safety scanner and a safety door on its own.

Contact your local Pilz representative or visit PNOZmulti 2 small controller - Base units - Pilz CA for more information!

For more information

Please enter your email to learn more.