Manufacturers seek integrated motion control solutions, MA poll indicates

October 25, 2023

By

Sukanya Ray Ghosh

Motion control technologies play a crucial role in automating manufacturing facilities. They enable precise and efficient control of machinery and robotic systems. They ensure consistent and accurate movement of components, leading to higher product quality and reduced waste. Motion control systems can optimize production speed and cycle times, increasing overall output and productivity. They enhance worker safety by minimizing the need for manual labour in hazardous environments. Additionally, motion control solutions enable real-time monitoring and adjustment of manufacturing processes.

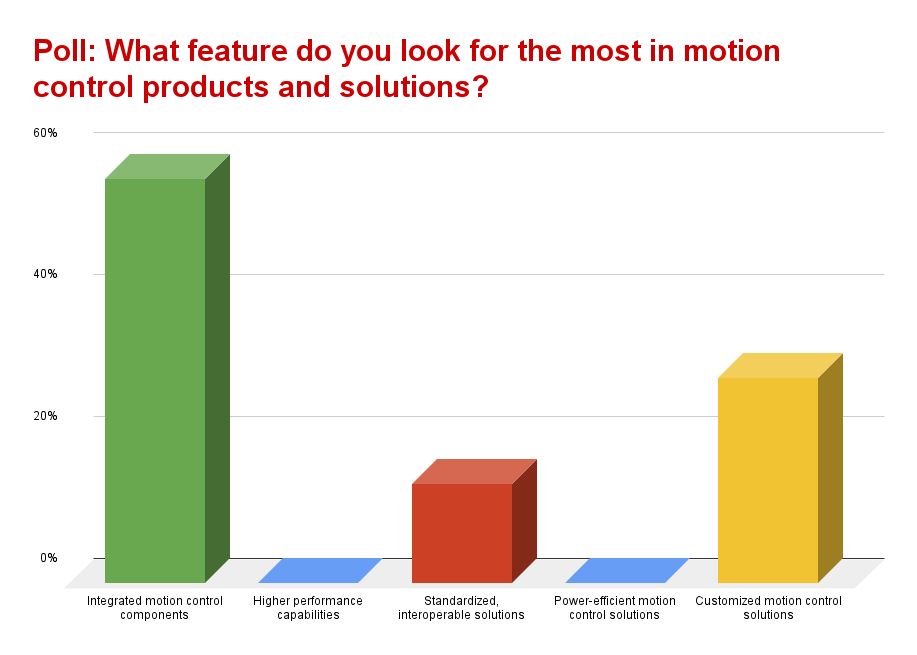

In a recent Manufacturing AUTOMATION poll, manufacturers shared the types of features they seek when considering motion control technologies and products for implementation. A whopping 57 percent of the respondents shared that they prefer integrated motion control components and solutions. It is not particularly surprising that manufacturers prefer compact packages comprising different motion control components as part of one integrated solution. Integrated solutions simplify the design and deployment processes and even allow for optimization of productivity.

Off-the-shelf products are becoming less popular with manufacturers today who seek customized automation solutions that can address their specific needs. Accordingly, 29 percent of the poll respondents shared that they prefer customized motion control solutions. Automating manufacturing processes and systems is often not an easy or inexpensive project for many manufacturers. Consequently, they hope to maximize ROI and ensure success from the get-go with custom solutions.

Another 14 percent of the respondents shared that they prefer standardized, interoperable motion control solutions. The ask for interoperability is seeing an uptick in recent times as manufacturers want the flexibility to choose their prefered automation solution an integrate it with their existing automated equipment and technologies. Interoperability allows different devices and equipment from various manufacturers to seamlessly work together, promoting flexibility and adaptability in production processes. It reduces downtime and maintenance costs, as components can be easily replaced or upgraded without requiring extensive reprogramming or reconfiguration. It also supports scalability, allowing manufacturers to expand or modify their automation systems without significant disruptions.

Interestingly, when selecting motion control products, features such as high-performance and power-efficiency are not in the consideration criteria for manufacturer. No respondent indicated either of these features as their top consideration for motion control products.

Advertisement

- Moticont releases two new linear voice coil motors

- AutomationDirect adds proximity sensors from Balluff’s BCS series