The big picture: Quantum sensing technologies and their impact on manufacturing

January 22, 2024

By Stephanie Holko, NGen

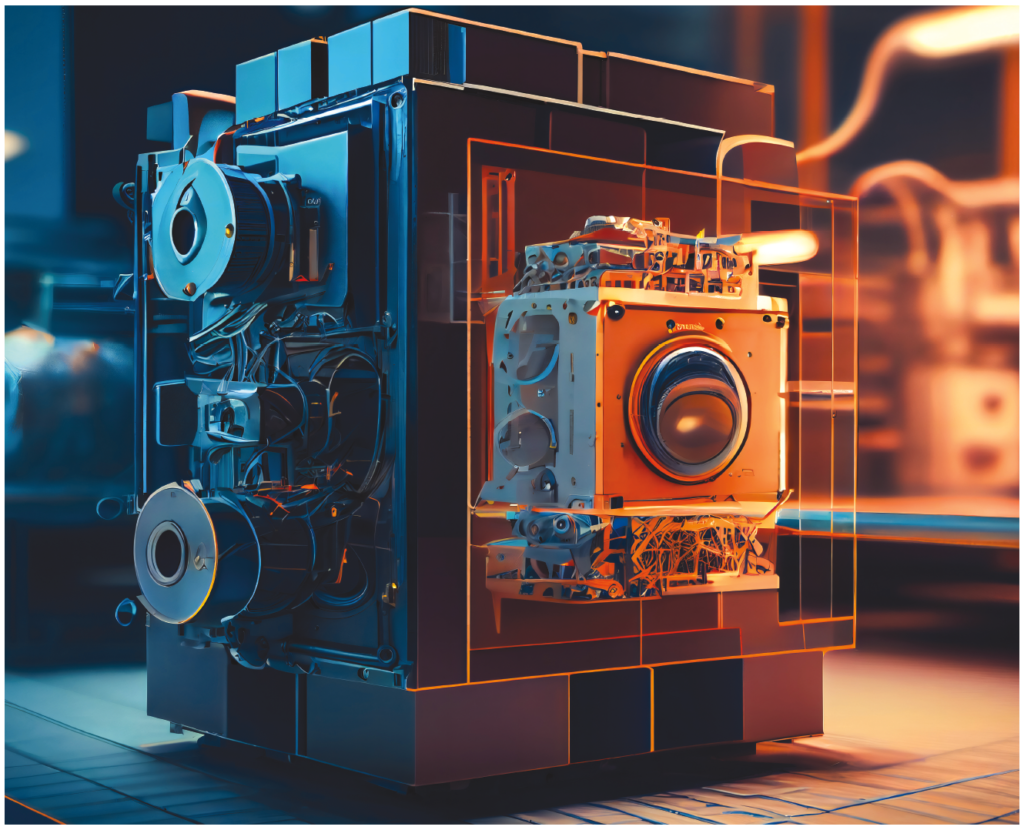

PHOTO: © EwaStudio / Adobe Stock

PHOTO: © EwaStudio / Adobe Stock As a broad umbrella, quantum sensing manipulates quantum properties of matter and energy to measure a sensitive dimension. In this article, we will discuss the types of quantum sensing technologies, their implications in manufacturing and where the field is headed. Quantum sensing is, believe it or not, an area of technology that has been around for over 50 years. Quantum sensing is in use today: in lasers including LIDAR, magnetic resonance imaging (MRIs), and photo-voltaic cells.

While society has enjoyed the benefits of these technologies, they are less well-known than the much-discussed quantum computing and quantum communication. The often-mentioned “quantum advantage” speaks to the ability of quantum computers to solve problems in drastically shorter time frames, making previously unrealistic complex problems approachable. Quantum communications are usually discussed in the context of cyber-security. Both areas are developing rapidly but are several years out from being commonplace.

Quantum sensors exploit the same property that makes quantum computing and communications such a challenge: sensitivity to external disturbances. Flipping this to our advantage allows us to measure very small and delicate phenomena with much greater accuracy and capacity.

The main approaches for quantum sensing are photonic and solid-state systems. Photonics deals with the manipulation of light in many ways, and solid-state systems deal with a sensor that is in a known quantum state and that changes with interaction with the stimulus (what you want to measure). Within these approaches, quantum-sensing technologies can be grouped into five distinct categories with complementary benefits.

1. Quantum imaging – this is useful for detecting moving or hidden objects using quantum LIDAR and/or radar and the most well-known applications are for defence.

2. Quantum electromagnetic sensors – these sensors measure dynamic electromagnetic fields using nitrogen vacancy centers, atomic vapours and superconducting circuits. They are also used in defence applications, but also in healthcare, such as MRIs.

3. Gravimeters and gradiometers – these measure the strength and changes in gravitational fields, respectively. The current applications include geophysical phenomena below-ground, primarily used in the energy sector to find reservoirs.

4. Thermometers and barometers (measuring – you guessed it—temperature and atmospheric pressure, respectively) – these specialized tools are much more sensitive than those commonly employed by using cold atomic clouds and superconducting quantum interface devices to achieve higher levels of accuracy in applications where it is critical, such as in submarines or aircraft.

5. Specific sensing applications that combine with quantum computing or communications or both. These applications require further development, as quantum computing and communication technologies mature.

Originally, quantum sensing was included in products we consider commonplace today, such as digital cameras. The next generation of quantum sensing technologies that are commercialized will benefit manufacturers in numerous ways: by providing extreme sensitivity in measurements that require precision and accuracy, and with new use cases regularly in aerospace, bio-medical, chemical, automotive and telecommunications industries. This is possible because these sensors use the quantum properties of a system to measure minute physical changes and signatures in those systems.

The next generation of quantum sensing technologies are being designed to be smaller, lighter and more cost-effective than the previous versions, and provide incredible resolution of measurement as compared to traditional sensing technologies. Early use cases include quality control measurements of high-quality products by identifying microscopic defects, strict measurements of precision products, and non-destructive testing by being able to measure hidden things below the surface.

Currently, the barriers to the adoption of next-generation quantum sensing technologies include the cost and time for development, which may delay the adoption industry-wide. Other challenges include the integration of new sensors with existing data frameworks and standardization within the industry – these problems mirror many of the challenges in adopting and uptake of emerging technologies. Industries with lower sensitivity to price and that stand to benefit the most will lead the charge. Once the defence, biotechnology, and automotive industries prove the applications and business cases of these sensitive technologies, there will be other use cases that emerge as the technology develops and scales. As the manufacturing industry embraces new technologies to improve precision and flexibility without sacrificing quality or productivity, the methods and techniques for measuring at greater resolution become more significant.

It will be important to pay attention to the benefits that can be achieved by combining other leading technologies with quantum sensing, such as wireless networks. Manufacturing-adjacent industries, such as construction and mining, stand to benefit as well. If technology develops these sensors to be small and inexpensive enough, they may make their way into your smartphones as well.

For those interested in exploring the power of next-generation sensing technologies, NGen and Digital Global Innovation Clusters are jointly administering funding for collaborative quantum commercialization projects, including quantum sensing. Please visit https://quantumadvantage.ngen.ca/ to learn more.

Stephanie Holko is the director of project development at Next Generation Manufacturing Canada (NGen). She loves connecting emerging technologies with existing manufacturing problems and believes the future of manufacturing is in the adoption of new ways of working. Stephanie is a licensed Professional Engineer in Ontario.

Advertisement

- Rapid rise in robotics adoption: Global average robot density doubles in just six years, IFR finds.

- Flexxbotics secures investment and mentorship from SolidWorks and Onshape co-founder