Top 10 Under 40 2023: Meet Joshua Pickard, director of innovation at Eigen Innovations

July 17, 2023

By

Sukanya Ray Ghosh

Manufacturing AUTOMATION’s second annual Top 10 Under 40 highlights the next generation of leaders who have demonstrated exemplary work ethic. They are leading the charge in their workspaces and inspiring their peers with their commitment to innovation.

This year, the winners share what they enjoy the most about working in the automation space, what plans they have for their future and suggestions on getting more people into this industry.

To highlight the achievements of each individual selected for the Top 10 Under 40 list, Manufacturing AUTOMATION will feature one of 2023’s winners every week for the next 10 weeks.

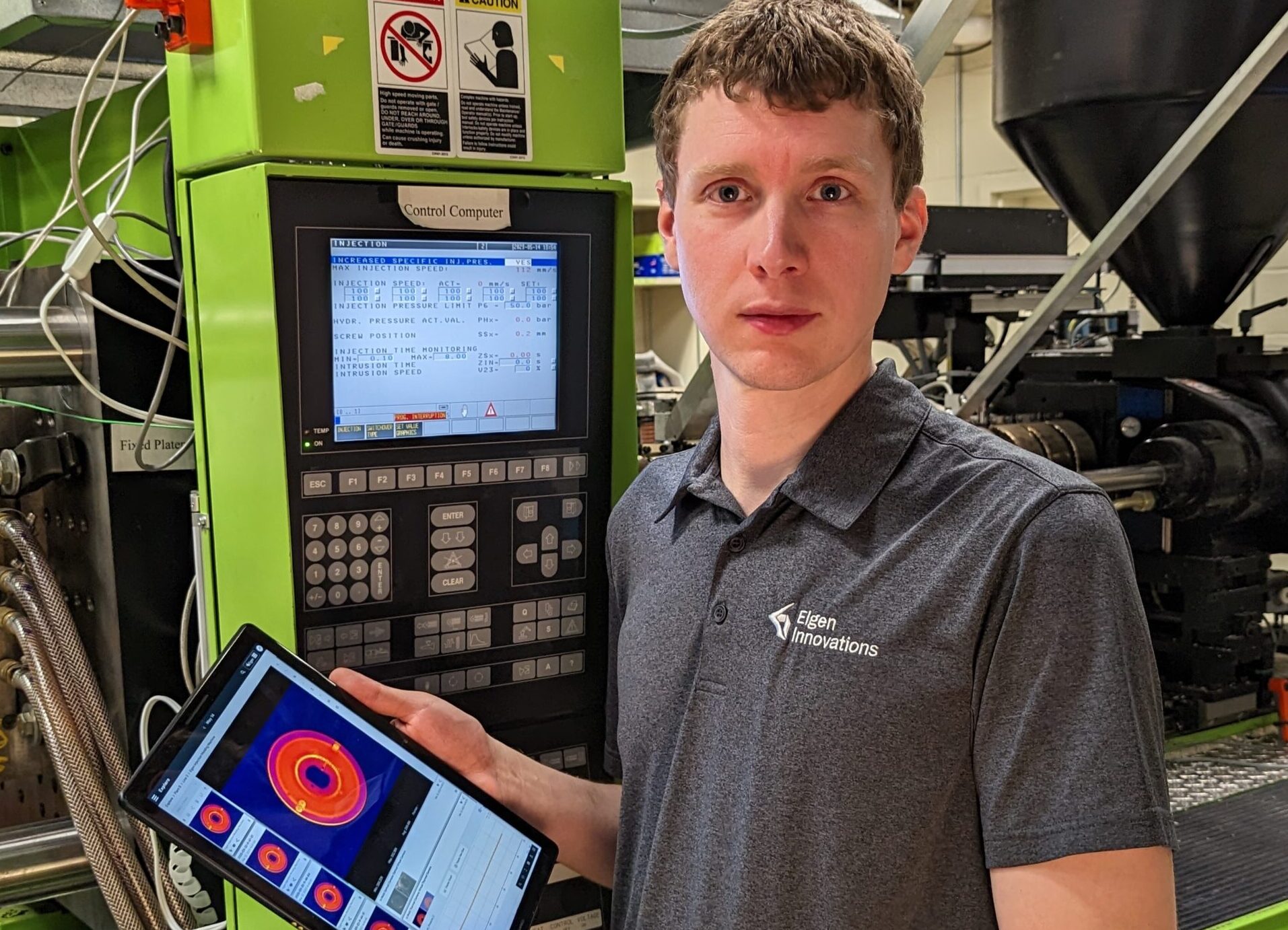

This week, we introduce Joshua Pickard, director of innovation at Eigen Innovations. Pickard shares his thoughts on his role, background and future plans.

Manufacturing AUTOMATION: What do you enjoy the most about working in the manufacturing/automation space?

Joshua Pickard: The manufacturing/automation space is highly dynamic with endless variations in the implementation of technologies and processes. Each new application can present new challenges, my overarching motivation is to uncover and create technologies that can help solve the big problems that hinder progress to unlock new possibilities in the space. It’s an exciting time to be involved in manufacturing/automation, with the rapid growth of new sensor technologies and automation tools combined with continually improving machine learning tools, many old and previously unsolvable problems suddenly become solvable. In many cases, the technology challenge is no longer whether a problem can be solved, rather what is the best and fastest approach to solve it. You quickly learn when building solutions to problems that there are many similarities in technology requirements. Building scalable technology that accelerates progress in the space, rather than one-off solutions, is a worthwhile investment. It’s our mission at Eigen and it’s the focus of my career. It’s reassuring to know that the ever-increasing complexity of processes and products means that there will be endless challenges to solve and technologies to create, it’s a great motivator.

MA: Besides professional training, what has helped you develop your skills the most?

JP: I was given some great advice early on in my career that has had a substantial influence on who I am as a person and how I approach problems. Today, I share this same advice with everyone on my team at Eigen. That advice is to always think critically, question everything that you are doing, and think ahead to make sure you are doing the right things today. In the pursuit of progress, it is important to understand the why and the how to know that you are making the right decisions and the best use of time. Beyond this, being ambitious has probably been one of my most defining characteristics. I have a strong desire to solve big and complex problems that unlock exciting new possibilities. My doctoral and post-doctoral studies and early professional experiences were perhaps the most important aspects of my skillset development. Working with and building a team of experts, collaborating externally to solve challenges that exceed current skill sets, seeking out resources and tools to augment existing knowledge and skills, and remaining focused on the big picture, are my main considerations today. One key insight, based on all of my learnings, is that growing the right team guided by the same principles and promoting effective collaboration is the best way to develop new skills and make rapid progress.

MA: What are your future plans within the industry?

JP: Today, the manufacturing and automation space is highly disjointed. When we talk about integrating technologies in a factory, we have numerous companies providing sensor and automation technologies, other companies providing analytics tools and hardware, process operators that thoroughly understand the process but are unfamiliar with available technologies, and integration companies that develop customized solutions as a service. Accelerating progress within the space requires rethinking current approaches to adopting technologies and figuring out how to remove existing hurdles and barriers to entry that can make adoption challenging. The main question for me going forward is ‘What innovations are needed to unlock increased technology adoption rates and rapidly push the space forward’. There are endless opportunities for improvements in the space, but focusing on scalability, flexibility, and ease of adoption must be primary considerations.

MA: How can this industry encourage more people to join and pursue successful careers here?

JP: My recommendation for encouraging more people to pursue manufacturing/automation careers is to promote where the space is heading, showcase what the adoption of technologies is enabling, and outline the exciting opportunities that are now becoming possible. Repetitive and mundane tasks are being replaced with automation and new technologies are helping to push product quality beyond what was previously possible. Industry 5.0 focuses on the augmentation of individuals so that they can achieve more, leading to more fulfilling and rewarding careers and improved productivity for the company. Opportunities in the space are increasing for open-minded individuals who promote, understand, and leverage new technologies. Having been involved in the development of state-of-the-art tools and knowing what is soon to be possible, it is indeed an exciting time to be involved in the space.

Advertisement

- RS adds to its smart manufacturing solutions with five new suppliers

- SONAMI adds advanced manufacturing capabilities with its latest expansion efforts