An environmental journey: Kruger’s new sustainability strategy proves the company is in it for the long haul

March 29, 2011

By Vanessa Chris

With a business built around an industry as fragile – and as close to Canadians’ hearts – as forestry, it’s not a surprise that Montreal, Que.-based Kruger Inc. was an environmental force before it was chic to be green.

The century-old manufacturer of such paper products as Cashmere, Scotties and Sponge Towels launched its first reforestation program more than 60 years ago – well before it became industry standard. In the 1970s, it produced its first line of recycled bathroom tissue.

With this type of track record behind it, it seems only natural that as the notion of “going green” increasingly penetrates the vernacular of both the company’s suppliers and consumers, Kruger would continue the tradition of staying ahead of the curve.

Enter Sustainability 2015 – an aggressive, forward-thinking mandate designed to significantly reduce the company’s environmental footprint on its manufacturing subsidiary, Kruger Products L.P.

“A typical sustainability strategy has four points – energy, emissions, water consumption and waste. We created nine,” says Steven Sage, corporate director of Sustainability and Innovation at Kruger Products L.P. “We had to figure out what made sense to our business. For us, it’s about fibre, forestry and reducing packaging, as well.”

While the company had already launched environmental efforts in a number of areas, it discovered the need for a branded, organized strategy when it started receiving calls from suppliers asking for specific environmentally focused information.

“We had a lot of things going on regarding sustainability, but it wasn’t packaged as such,” says Sage. “Lots of things were happening, but there wasn’t one focus point that we could discuss with customers.”

Without an organized strategy – and all of the necessary information collected in one place – the company found that it didn’t always have the answers for its enquiring suppliers. More and more customers were asking for finer details – such as the total units of water usage – and they wanted third-party verification of these details. While Kruger may indeed have been better than most in these areas, it didn’t have the statistics easily on hand to prove it.

It was around that time that upper management decided a long-term sustainability strategy was required, and a new position was needed to guide the efforts. So, in the summer of 2008, they hired Sage.

Resteering the ship

One of Sage’s first orders of business as the company’s corporate director of Sustainability and Innovation was defining what “sustainability” meant – a task that proved more difficult than you would think.

Not only is it a broad term, but it means different things to different industries. The ultimate goals of a sustainability strategy for a company like Kruger, which is closely connected to the forestry industry, would be much different than a company that was interconnected to the oil and gas industry, for example.

“One of the hardest things on a leadership level was to establish a consistent view of what sustainability meant,” says Sage. “We had to define what sustainability meant to us. You can’t buy this type of strategy off the shelf.”

Once upper management had decided on a definition that they felt truly reflected their company’s goals and situation, the next step was to clearly lay out the necessary metrics and benchmarks.

“It’s important, internally, to know what your goals are,” says Sage. “But metrics and benchmarks are also necessary when communicating your goals and progress to external parties.”

So 2009 was set aside as the benchmarking year. The company accumulated information to see exactly where it stood on its nine sustainability targets – and where it needed to go. In some situations, the company found it had to provide resources to certain facilities that previously weren’t properly equipped to keep track of the required metrics. In other instances, the company found that the new data immediately presented them with a wealth of new information.

“There are so many things we’ve learned by defining this program,” says Sage. “We have much more information available to us to help us make better decisions.”

Making the green choice

Once the benchmarking and goal-setting was completed, the program was rolled out in 2010. On the mill level, at the company’s four Canadian papermaking mills in Crabtree, Sherbrooke and Gatineau, Que., and in New Westminster, B.C., as well as its Memphis, Tenn., facility (which operates as Kruger Tissue Group USA), this meant that a lot more things had to be measured – from electrical usage to steam usage. The environmental strategy was noticed and embraced throughout the company, particularly on the mill floor. Many employees even went beyond the 2015 strategy and started to “go green” on their own accords.

“You see a much greater focus on elements of the 2015 initiative on the plant floor now,” says Chuck Stewart, regional manager of Region West Manufacturing, at the company’s New Westminster mill. “More ideas are coming in from the floor. Instead of printing, more people are scanning. People are coming into work via motorcycle instead of cars. We’ve even designated a section of the parking lot for motorcycles only.”

One environmental initiative that brought the greatest sense of pride to the New Westminster, B.C., mill as a whole was the company’s state-of-the-art biomass gasification system. When the mill was forced to decommission a 50-year-old boiler, management was faced with a difficult decision. Should they replace the boiler with a less expensive natural gas boiler, or a more environmentally friendly, cutting-edge biomass gasification system?

Thanks to the new mandate set out by Sustainability 2015, the facility was given the go-ahead to pursue the latter – which cost approximately 80 percent more than the natural gas boiler.

When trees get processed for lumber mills, the skin – or bark – must be removed. This woody debris – which can also consist of other wood waste, such as tree trimming and land clearing debris – is referred to as “hog fuel” or “biomass,” and is the fuel behind a biomass gasification system. This woody mass is heated to a certain temperature until it creates a combustible gas. The gas is then used to boil water and provide fuel for the boiler.

“We use the steam for heating purposes throughout the facility – both in the production of paper products and paper machines,” says Stewart. “We saw a 33 percent reduction in greenhouse emissions in 2010, and that was our first year of use.”

While Stewart knows the new biomass gasification system will eventually save the company money, pinpointing the exact ROI timeline is difficult.

“ROI is dependent on the cost of biomass material, and that’s driven by availability,” he says. “At the same time, we’re looking at very low prices of natural gas right now, but those will vary over time.”

Overall, Stewart estimates it will take between six and 10 years before the company recovers the full investment. In the meantime, the new equipment has resulted in a huge sense of pride for the facility.

“We’ve been a real showcase in the west,” Stewart says, adding that the company frequently invites visitors in for tours of the equipment. “This has had a wonderful impact on company morale, as well.”

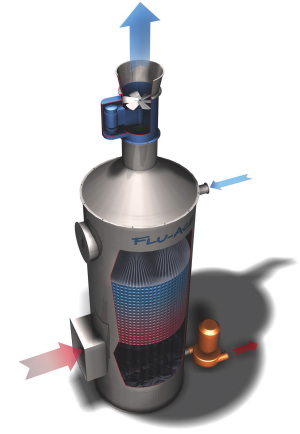

Another example of the company’s environmental commitment is the implementation of heat recovery technology in its Gatineau, Que., mill late last year. A $4.8-million investment, this technology is expected to lower the mill’s total energy consumption by 11 percent and CO2 emissions by 14.5 percent (10,000 tonnes per year), a reduction equivalent to removing 2,500 cars from the road or planting 1.3 million trees.

The central heat recovery system captures hot, humid air from the mill’s paper machines and reuses it to heat process water, as well as the facility during the winter.

Beyond 2015

Advanced measures such as the biomass gasification system in New Westminster, as well as the heat recovery system in the Gatineau facility, are direct results of the company’s Sustainability 2015 initiative.

“If we didn’t have the 2015 initiative, I don’t know what (boiler option) we would have chosen,” says Stewart. “It’s definitely easier to get these changes made under Sustainability 2015. We can look at projects on a greater scale with longer paybacks.”

That being said, Stewart stresses that, while a company-wide program and upper-management buy-in is a definite luxury, there are plenty of things individual facilities can do on their own that will both save money and reduce environmental footprints.

“Local facilities – independent of external guidance – have to be willing to reach out and explore their options,” he says. “They’ll likely find more options than they think they will that offer financial and environmental gains. Buy-in from the top is helpful, but not necessary.”

Stewart points to the motorcycle-designated portion of the parking lot as one example of an emissions-saving measure that didn’t cost the company a cent. Kruger Products’ VP of technology, Frank van Biesen, adds that some of the easiest and most effective improvements came from simply repairing machines that weren’t operating properly. Certain lighting efficiency efforts were also relatively simple and inexpensive – such as changing light fixtures and replacing outdated fluorescent bulbs.

“Various hydro incentives were also very helpful to us – programs that were available through provincial governments and sometimes the hydro companies themselves,” he says. “Utility companies are often eager to help with sustainability projects because they’re looking for ways to better manage their supply.”

Van Biesen adds that, in many situations, sustainability measures can help you deal with an issue you would have eventually had to tackle. He offers the example that certain fluorescent bulbs are eventually not going to be manufactured anymore, so it makes sense to take advantage of an incentive to switch now to more energy-efficient lighting options.

For now, Kruger Products L.P. is looking at the small and large steps it can take to reach its 2015 targets. On the horizon? Increasing employee involvement by developing a program that will encourage more ideas from the mill floor. The Westminster facility is also looking to expand the biomass gasification system, and bring in new machinery that will allow it to minimize the amount of corrugate and poly wrap used in its various products.

Above anything else, Kruger is viewing this next phase of environmentalism as a journey, rather than a project that needs to be completed.

“One thing we’ve learned is that there’s not one silver bullet,” says Sage. “There are so many different ways to approach sustainability. We’re constantly looking for ways that make sense for us.” _

Vanessa Chris is a Toronto, Ont.-based freelance writer.

Kruger’s sustainability strategy

TARGET #1: Manufacture our products using only 100 percent third-party-certified fibre, ensuring that the fibre in our products comes from only sustainably harvested forests and/or recycled material containing a high percentage of post-consumer waste.

TARGET #2: Receive Chain of Custody Certification, thereby assuring our customers that the fibre we use can be tracked back to an approved source.

TARGET #3: Reduce our packaging by five percent without compromising product protection standards, while also increasing our use of recycled, recyclable and biodegradable packaging materials.

TARGET #4: Add to our more than 90 third-party-certified products and continue to be the leading manufacturer of such innovative tissue paper products.

TARGET #5: Reduce our overall energy consumption by 15 percent by streamlining our manufacturing processes and implementing an array of energy-reduction and efficiency initiatives.

TARGET #6: Reduce our greenhouse gas emissions by 15 percent by reducing our consumption of traditional energy and increasing our use of alternative and renewable energy.

TARGET #7: Reduce our emissions from transportation by 15 percent through improved logistics and shipping efficiencies, and increased use of lower carbon-emitting modes of transportation, such as rail.

TARGET #8: Reduce our total water consumption by 15 percent, without compromising our wastewater treatment standards that are already substantially in excess of government requirements.

TARGET #9: Reduce the amount of solid waste and manufacturing byproducts that we send to landfill by 20 percent through a systematic program of industrial-grade recycling, reuse and reduction initiatives.

Source: Sustainability2015.ca

Tips for launching a successful sustainability strategy • Designate an in-house position to lead your sustainability strategy. While it might seem more cost-efficient to create “add-on” tasks for existing personnel, this will likely lead to important initiatives falling through the cracks.

• If you decide to hire third-party consultants to help you along the way, make sure the strategy is owned by the organization, first and foremost. When the consultants leave, you want to make sure the strategy is able to be sustained internally.

• Decide what “sustainability” means to your organization. With your definition in hand, uncover metrics and benchmarks that will best reflect your progress toward sustainability.

• Don’t be distracted by high-end projects. Smaller, more cost-effective projects may be the easiest ones to launch – and may end up having a significant impact.

• Look for financial assistance. There are many government grants and incentive programs out there designed to assist companies in devising sustainability strategies. Contact your federal and provincial governments and/or local electricity company to find out what programs they offer.

• Promote transparency. Make sure you’re following through on your goals and reporting your results for both your customers and employees to see. The goal should be to show – not tell – your key stakeholders that you mean business.

Advertisement

- Healthy and FIT: A look at Ontario’s green energy growth

- The greening of machining: A holistic approach to machine tool design reduces metal cutting’s environmental impact