Grain-processing equipment maker designs using digital prototyping

February 23, 2010

By Autodesk

If you’ve ever eaten corn flakes or planted a seed, chances are A.T. Ferrell Co. Inc. has touched your life.

If you’ve ever eaten corn flakes or planted a seed, chances are A.T. Ferrell Co. Inc. has touched your life.

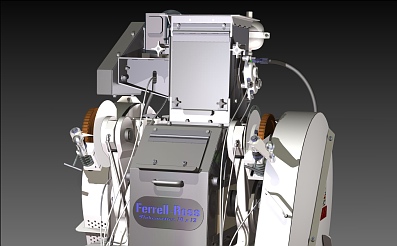

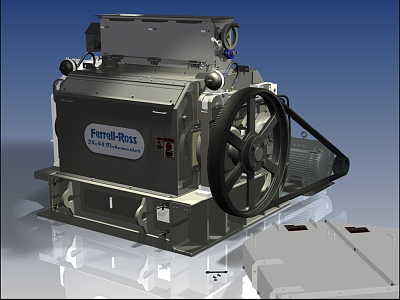

A leader serving agricultural, food and industrial markets, A.T. Ferrell has been designing and building equipment used to process, condition and convey grains, feeds, seeds and other bulk and powder materials for 140 years. The products its three divisions make are used and trusted by feed mills, farm operators and food, cereal and oilseed processors worldwide. Many customers have relied on their equipment and expertise for decades to maximize their profits. As a result, A.T. Ferrell needs to be agile and responsive, continually innovating their designs to deliver superior results and performance for their customers.

The company has moved beyond 3D to digital prototyping, enabling it to design, visualize and simulate the real-world performance of its products before cutting a single piece of steel. Autodesk Inventor software has helped A.T. Ferrell to:

• Better support its customers

• Help lower costs and increase innovation

• Avoid costly mistakes, speeding product development time

• Use a single digital prototype for design, sales, marketing and manufacturing

• Reduce reliance on expensive physical prototyping

The challenge

To meet each customer’s requirements, A.T. Ferrell configures its equipment to order, to meet customer needs, now and in the future.

“Even though we have common chassis concepts, there are 15 to 30 variables that come into play when we build a customer’s machine,” explains Allen Gager, design engineer and CAD manager at A.T. Ferrell. “Adding to the complexity, we try to account for likely future processing techniques so that our customers can use our machines 20, 30, even 40 years from now,” he adds. “One reason that A.T. Ferrell has been so successful for so long is that our customers trust us to maximize their investments.”

In addition to addressing customer needs cost-effectively, A.T. Ferrell’s food-grade products are subject to FDA and other government regulations. The company must also design its product with the safety of maintenance workers in mind to address Occupational Safety and Health Administration (OSHA) guidelines.

The solution

The solutionA.T. Ferrell adopted Autodesk Inventor Professional software and Autodesk Vault Workgroup data management software, both part of the Autodesk solution for digital prototyping. They help A.T. Ferrell streamline its product development, sales, and marketing processes, from initial product configuration through manufacturing and beyond.

The company uses Inventor Professional software to design the mechanical and hydraulic systems on its machines and Vault to reuse designs, track revisions and release finished designs to manufacturing.

According to Gager, with this digital prototyping solution, A.T. Ferrell can create superior, optimized designs faster than ever. He says, “Taking advantage of digital prototyping, we can look at a number of different ideas for a solution before we cut steel. We can simulate and analyze our designs to minimize mistakes — and in the end provide a better product.” For example, A.T. Ferrell uses the built-in finite element analysis (FEA) capabilities to optimize material choices and sizes. “We can apply forces and stresses to find out how much material we really need,” he continues. “If we use material intelligently, we can cut costs and reduce our energy footprint. It takes less energy to cut a half-inch of steel than three-quarters an inch of steel.”

The company can also better meet regulatory requirements with the help of Inventor. Gager explains: “During the design phase, we can address applicable regulations. For example, it’s easier to meet OSHA regulations because we can get accurate weight on panels that need to be removed during maintenance — and thus determine whether a worker can safely move and manipulate them.”

Easier to ask “what if?”

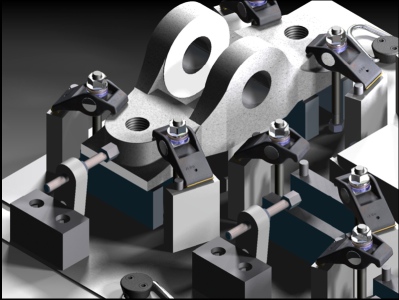

Recently, A.T. Ferrell experienced design optimization at its best when a customer asked the company to improve ease-of-use for a roller mill adjustment system. Gager immediately began to explore different options in Inventor. “I pulled up the model and just started asking ‘what if’ questions,” he says. “I went through about 15 scenarios to find a solution. I worked with our machine builder to make some minor revisions and then ran stress analysis and checked for interferences before we finalized the model. Finally, we generated shop drawings and went into production. It took just over two days from start to finish.”

When asked how the company would have met this type of customer request before adopting Inventor software, he says, “We probably would have made four physical prototypes and there would have been 12 people involved. Inventor removes the risk of asking ‘what if’. I explore a wide range of design options without wasting time or money.”

Digital models drive sales

Digital models drive salesThe optimized digital prototypes A.T. Ferrell creates in Inventor software drive not only product development but also help the sales team. “Digital prototypes make it easier to collaborate with our global customer base,” Gager says. “Customers can collaborate with us on their designs by viewing DWF™ files. They can explore designs from every angle to make sure that we’ve met their needs and there are no surprises when the machine arrives for installation. Our customers can even import Inventor data into Autodesk Navisworks software to help speed their facilities layouts.”

In addition, A.T. Ferrell uses renderings from digital prototypes in its manuals and generates code for computer numerically controlled (CNC) machines directly from Inventor models. “When you’re trying to communicate using 2D engineering drawings, there can be communication barriers,” he notes. “But with 3D digital prototypes, those go away. From sales to marketing to manufacturing, everyone gets what they need right off the digital model. That’s certainly not possible with 2D geometry.”

The result

A.T. Ferrell is delivering the exceptional quality customers expect — and saving time and money in the process. “Without Inventor and Digital Prototyping, we would have to make several physical prototypes for each new design,” Gager says. “We still build them on occasion, but it’s rare now.”

In addition, the company has created a custom Inventor application to automate aspects of sheet metal design. “Something that took a few minutes to do before now takes a single click,” he says. “For machines with 300 sheet metal parts, that adds up.”

Gager estimates that Autodesk software reduces the workload of A.T. Ferrell’s designers by half. But more than that, Autodesk software frees them up to be creative. He says, “Instead of locating, opening, and printing hundreds of drawings in a project, we use Autodesk Vault Workgroup to complete the process with just a few clicks. As a result, we can spend time working on the fun stuff, which is designing machines that meet customer needs.”

www.autodesk.com/inventor

Advertisement

- CSA outlines revised power-press standard

- Industrial PC market driven by technological possibilities