Pleora expands Vaira manufacturing platform with advanced AI inspection tools

September 22, 2023

By Manufacturing AUTOMATION

Photo: Pleora Technologies

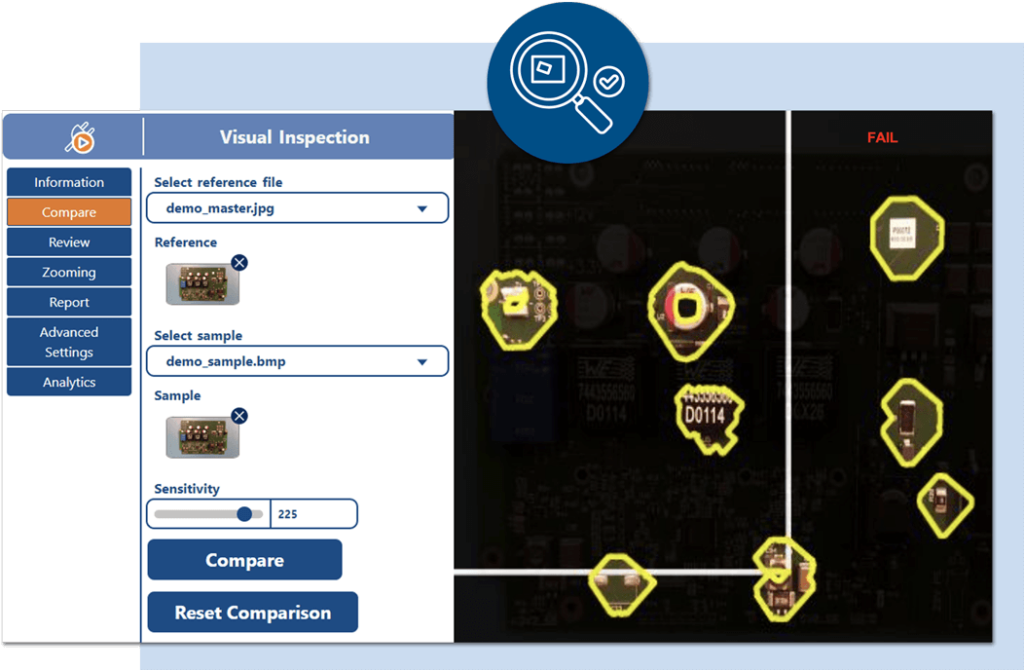

Photo: Pleora Technologies Pleora Technologies has expanded its scalable suite of shop-floor ready AI and digitization apps for its Vaira solution to help manufacturers automate and upgrade error-prone processes.

Expanding the capabilities of the solution, Vaira’s visual inspection app now includes AI-based object detection and classification skills that can be integrated with assembly checklist and work instructions, says the company in a press statement. With Vaira’s new inspection and checklist app, an electronics manufacturer has reduced final verification steps from over four minutes to 30 seconds. Vaira has also been deployed in electronics assembly, recycling sorting, and automotive, medical, utility and small parts manufacturing applications.

Vaira reportedly integrates machine vision cameras, lighting, edge processing, manufacturing system connectivity and a low-code development platform with a suite of customizable shop-floor ready inspection and traceability apps.

With Vaira’s combined inspection and checklist features an operator follows digitized instructions that guide product assembly step-by-step, while AI and machine vision automatically verifies quality.

For example, the app can check that the correct component has been used as part of an assembly and confirm that it is in the proper position. If a defect is detected the operator can’t move to the next assembly step until the error is corrected. Adding product tracker app capabilities, product images and operator notes are captured and stored to a manufacturer’s ERP/MES system for compliance, traceability, and continuous improvement initiatives.

“Vaira makes manufacturing decisions repeatable, reliable, and fully traceable,” says Jonathan Hou, president at Pleora. “Our app-based approach to AI deployment gives quality managers the tools they need to quickly solve critical issues that cost their business time and money while gaining data insight to guide their automation strategy. Continuously expanding our platform with new ready-to-deploy AI skills customizable to unique workflows helps manufacturers immediately improve quality.”

Advertisement

- Schneider Electric names new leader for its Canadian operations

- Registration now open for Automate 2024 coming to Chicago in May