Schneider Electric introduces EcoStruxure Plant Lean Management for data-driven decision making

February 29, 2024

By Manufacturing AUTOMATION

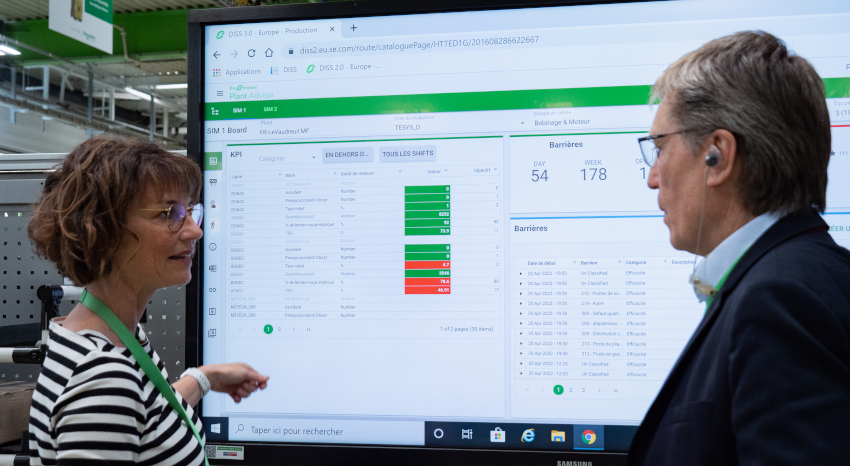

Photo: Schneider Electric

Photo: Schneider Electric Schneider Electric has launched EcoStruxure Plant Lean Management, a digital solution that reportedly collects and aggregates data across industrial operations to develop key performance indicators (KPIs) for short interval management (SIM) meetings, where shop floor teams review production cycles.

According to the company, EcoStruxure Plant Lean Management automatically collects the relevant Information Technology and Operational Technology data for KPIs on productivity, service levels, quality, safety and sustainability with real-time access to on-site or remote data. Its interface reportedly digitizes and optimizes SIM meeting cycles across one or multiple sites. The open platform, which can be implemented on any hardware, integrates with AVEVA Data Hub, a solution that aggregates and stores vast quantities of real-time data generated by Industrial Internet of Things (IIoT) devices.

“Digital transformation is not just a technological challenge, it requires a culture of collaboration and continuous improvement,” said Ali Haj Fraj, senior vice-president for the Digital Factory Line of Business at Schneider Electric. “EcoStruxure Plant Lean Management puts plant and supply chain information in the hands of workers, so they can make the best decisions in real time and boost productivity.”

Advertisement

Story continue below

Tags

- Global machine vision market to see recovery in 2024 and beyond: Interact Analysis

- Report: Canada’s manufacturing sector edges towards recovery in February