Syspro: Checking weather on Mars with ERP

September 19, 2011

By Syspro

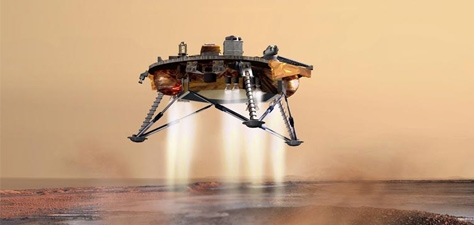

The Company: On October 23, 2008, NASA caught the attention of the world by announcing the detection of snow on Mars. The discovery was made by Canadian-made lidar (light detection and ranging) technology aboard NASA’s Phoenix Mars Lander, which touched down near the Martian North Pole on May 25, 2008.

Designed by Canadian-owned and operated Optech Incorporated, lidar probes and analyses the atmosphere above the lander.

“That’s us,” says Elizabeth Carswell, Optech’s chief financial officer. “We designed the lidar technology that sent the very first weather reports from Mars.”

Headquartered in Vaughan, Ont., Optech was incorporated in 1974 as a small research and development firm specializing in applications for laser technology. Today, with more than 200 employees and a wholly-owned U.S.-based subsidiary (Optech International), Optech is the global market leader in the development, manufacture and support of advanced laser-based surveying, mapping and imaging instruments. Each of Optech’s five major divisions shares a common mission — to use lidar in the design and manufacture of state-of-the-art precision measurement instruments.

The Challenge: In 1996, Optech installed Syspro ERP software to align its accounting and manufacturing processes, and to help the company conform with industry quality and compliance regulations. Today, Syspro is installed across all of Optech’s divisions, including its subsidiary in Kiln, Miss.

“We’ve been using Syspro for a long time,” Carswell says. “It was in the right price range at the time, and it really has grown with us.”

Two of Optech’s flagship products are the Airborne Laser Terrain Mapper (ALTM ) and the LYNX Mobile Mapper. The company uses Syspro’s Materials Resource Planning (MRP) module to build one-and-a-half of each of those every month.

“It’s a challenge to source the materials we need. Some of the parts are very high value, and we don’t want to receive them early. We’re looking forward to refining our MRP with the Advanced Trial Kitting module. In fact, we’re testing the latest version right now,” Carswell says.

Production, however, is only part of Optech’s business. Thirty-five percent of its work is R&D, all of which is done on a project basis. When Optech first looked at implementing an ERP system, the company was told by consultants that their Production and Research divisions would require two separate ERPs.

“Fortunately, we kept looking until we found Syspro, which had no problem running both departments,” Carswell says. “Syspro is very flexible – you can even use it with third-party applications. For example, we automate the input from timesheets using a different timesheet system. That’s allowed us to grow without changing everything in our accounting system.”

The Strategy: As Optech’s presence on the world stage has grown, the company has increased its number of Syspro licences on a regular basis, and added functionality by implementing additional Syspro modules.

According to Carswell, Optech uses a lot of Syspro modules, and not just for production and research.

“For example, we use Syspro to gather all the information we need for both Canadian and U.S. billings. When we’re working on a program for NASA, it goes through the Canadian Space Agency, and there are very strict billing requirements. In Canada we also have Scientific Research and Experimental Development (SR&ED) tax credits. Tracking the details for SR&ED is onerous, and we do all of that with Syspro,” she says.

To compete in the global — and extra-terrestrial — marketplace, Optech’s products must conform to stringent compliance regulations. The company’s quality management system facilitated the acquisition of CSA, FM and ATEX certifications. ATEX, in addition, requires Optech’s quality system to meet or exceed ISO 9002:2000 and prEN13980:2002.

“The Syspro operating environment played a major role in assisting Optech to achieve these agency certifications,” Carswell says.

A number of Syspro modules were used specifically to gain the required agency certifications. For example, the Sales Orders module processes and tracks customer deliverables and shipping dates, and allocates and reserves required inventory. Within the Purchase Orders module, Optech sets up its suppliers and tracks their efficiencies. In addition, all required parts for a product are processed through the Purchase Orders module to ensure accuracy and traceability.

The Inventory module provides Optech with the ability to align its warehouses with production process flow. It also allows the company to determine movement and duration of any particular component. Also within the Inventory module, the Product Configurator is used to identify mandatory and optional components during new product transfer to manufacturing.

“That allows us to easily track customer deliverables, thus ensuring accurate delivery of items to customers and timely invoicing,” Carswell points out.

The Bill of Materials module (BOM) is set up in conjunction with Optech’s design database tool to enable optimal accuracy of the overall component list for a product from design to production cycle. The component list is aligned with operations to ensure that the production process for that product is reflected on the BOM. Also through the BOM, multi-level trial kitting reports are used to monitor inventory levels and inventory turnover efficiencies.

Using the Valuation Report within the Work in Progress (WIP) module, jobs are created to track production build requirements and associated material and labour costs. This process permits Optech to monitor labour and material efficiencies against set standards and budgeted numbers. Moreover, WIP facilitates the streamlining of processes to further optimize product efficiencies in terms of labour and material.

The General Ledger module provides Optech with enterprise-wide financial reporting. The company runs labour, purchase price and warehouse variance reports, which allows it to further investigate any anomalies that might arise during the production build cycle, and to make modifications to the respective process if required. Finally, Optech uses the Accounts Payable and Accounts Receivable modules to improve its business processes and ensure compliance.

The Results: Currently, Optech is making plans to upgrade to Syspro’s latest version.

“Our business has grown and changed over the last 12 years,” Carswell says. “We’ve stayed with Syspro because of the ease with which it adapts to changes in the business process. Our industry is growing at about 15 percent each year, and Optech is expanding into new segments. Consequently, we’re predicting that our growth will accelerate, and we are confident that Syspro will continue to support us.”

A version of this case study ran as part of the 2011 Software Case Study Guide in the September 2011 issue of Manufacturing AUTOMATION.

Advertisement

- SolidWorks: Reducing production time with game-changing solution

- Software success: Controlling procurement and minimizing sales bias