Parallel picking: How to improve order-picking efficiency and accuracy in manufacturing operations

January 19, 2011

By Kardex Remstar LLC

Parallel picking is an order-picking technique that can be used to improve the efficiency and accuracy of order-picking operations in the manufacturing industry. It is often implemented into manufacturing picking operations when standard picking methods become too slow or constrictive.

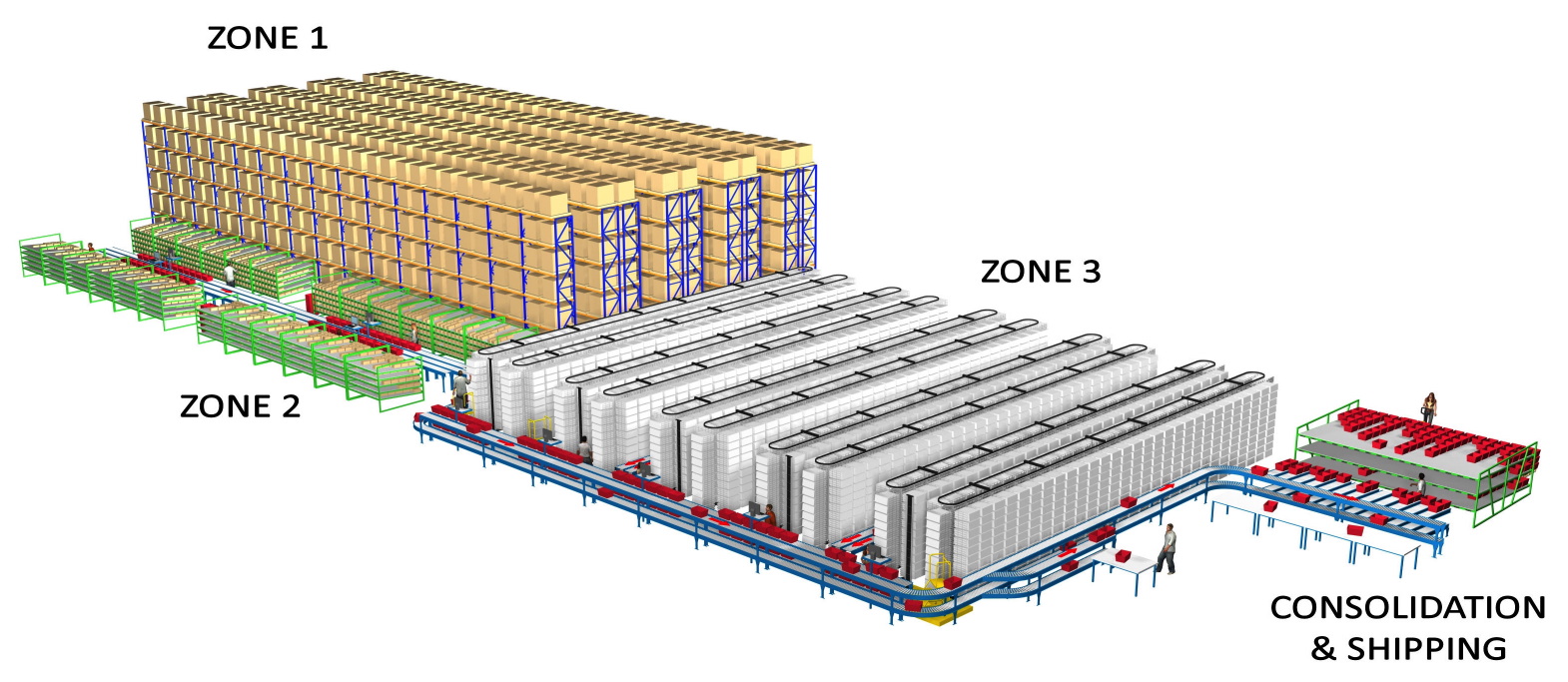

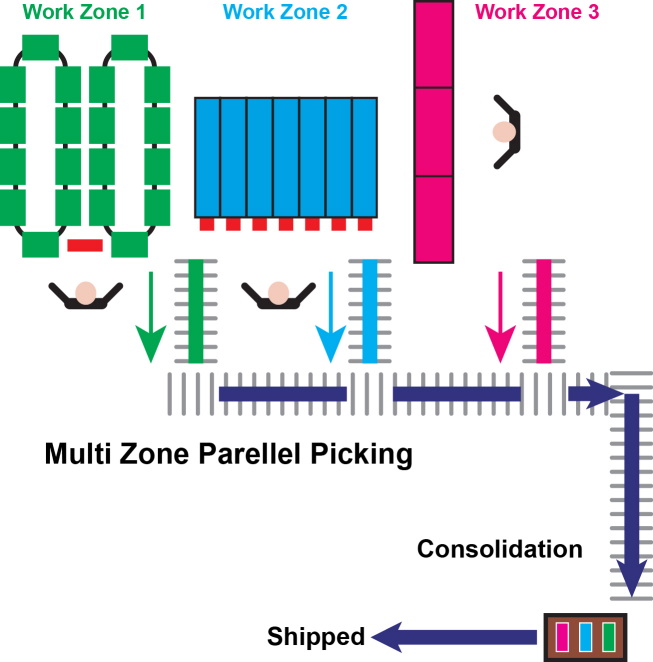

Using the parallel-picking method, the warehouse is divided into multiple picking zones. When orders are requested, stock keeping units (SKUs) are picked from each zone simultaneously, in parallel, and transported to order consolidation.

In a well-integrated parallel picking operation, each pick zone is matched with the optimum material handling technology. Based on the SKU profile of the work zone, material handling equipment, labour and velocity can be balanced to meet order-picking needs. For example, high volume parts can go into flow racks; medium to slow moving parts can go into vertical lift modules (VLMs), vertical and horizontal carousels; and very slow moving parts can go into rack and shelving systems. Using this approach, automated storage and retrieval systems can be used in conjunction with non-automated systems to provide optimum order-picking operations and create higher productivity.

Shifting philosophy

Parallel picking requires a shift in philosophy from picking an order to picking parts. In a traditional order-picking operation, employees criss-cross the warehouse, moving from storage location to storage location, searching for the parts necessary to fill a specific order. When an order is complete, it is delivered to a shipping area and the picker starts another order, retracing his earlier steps. Manufacturing operations that rely solely on traditional order-picking methods often can’t sustain the growth necessary to meet business objectives. Regardless of the number of order pickers added to the process, the quantity of orders eventually grows too large for the order pickers to keep up with.

Parallel picking, sometimes also referred to as zone picking, overcomes this problem by allowing the picker to focus on simply picking parts from an assigned zone, without concern for which order the part is destined. Once the parts are picked from a specific zone, they are sent to a consolidation area to await the parts required from the other zones. Once parts from each zone arrive at consolidation, the complete order is sent to packing and shipping. Keeping a picker in an assigned zone decreases walk and search time, and allows employees to spend more time picking, increasing productivity. Picking in a single zone also allows employees to become familiar with the technology associated with that zone, which in turn, allows them to make maximum use of the equipment.

When combined with inventory management software and pick-to-light technology, parallel picking can result in significant improvements in accuracy. Directing the picker to the exact location and cell of the part required can increase accuracy up to 99.9 percent. Parallel picking also offers organizations the flexibility to integrate technology, such as pick-to-light, in stages starting with high volume zones for an immediate improvement in accuracy.

The key to continued success is to review part locations monthly and move them to more appropriate zones as they change. Fast movers may become medium movers, and if they stay in the fast moving zone, the picking operation can lose efficiency. To maintain maximum picking efficiency, it is important to review parts inventory on a continual basis.